Pole lug cutting device and pole lug cutting system

A cutting device and pole ear technology, applied in welding equipment, laser welding equipment, metal processing, etc., can solve the problems of instability, high working temperature, shortened belt life, etc., to achieve long service life, improve stability, and ensure cutting quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

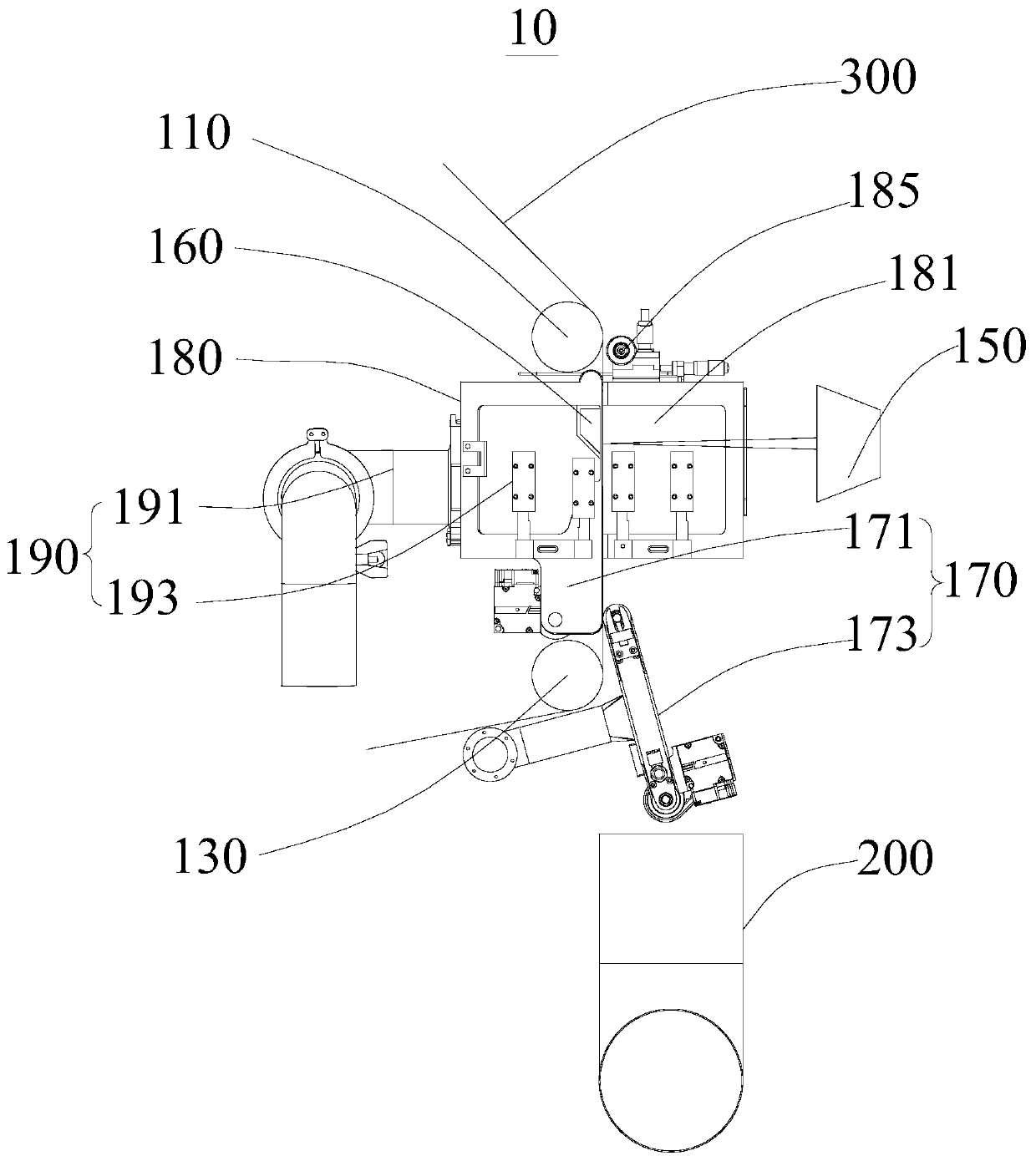

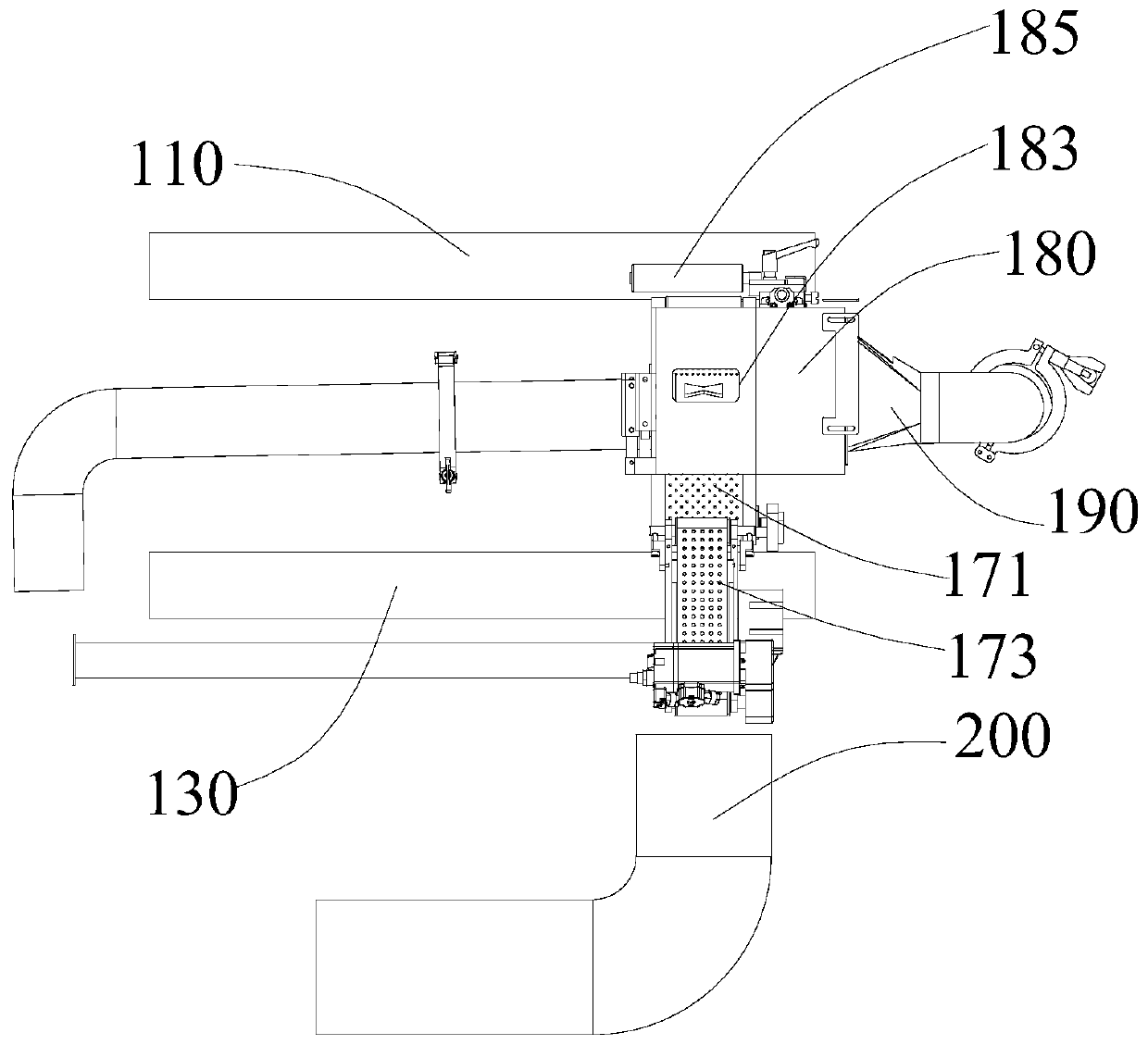

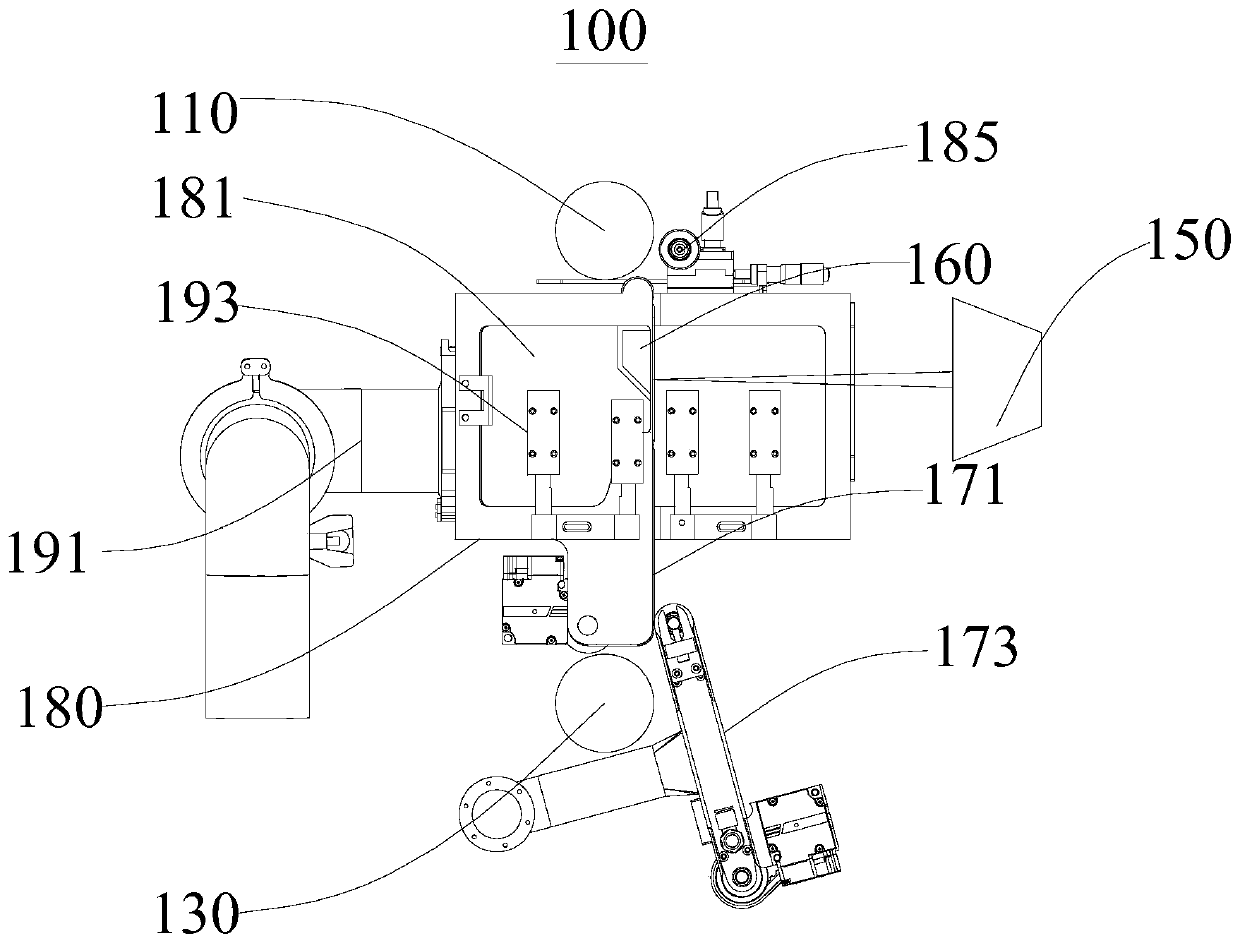

[0036] see in conjunction Figure 1 to Figure 5 , this embodiment provides a lug cutting system 10, including a waste pipeline 200 and a lug cutting device 100, the lug cutting device 100 is used to cut the pole piece 300 and send out the waste generated by cutting, the waste pipeline 200 is set in Below the tab cutting device 100, the waste generated by cutting is collected by gravity.

[0037] The tab cutting device 100 provided in this embodiment includes a first support roller 110, a second support roller 130, a cutting bottom plate 160, a laser cutting part 150, a lower waste mechanism 170, a cutting housing 180 and a dust removal mechanism 190. The first support The roller 110 and the second support roller 130 are arranged in parallel and at intervals for conveying the pole piece 300 , the cutting bottom plate 160 is arranged between the first support roller 110 and the second support roller 130 for supporting the pole piece 300 , and the laser cutting part 150 It is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com