Combined lifting type pipe fitting welding device

A pipe fitting welding and lifting technology, applied in the field of parts welding, can solve problems such as poor welding efficiency, inability to ensure that the parameters meet the requirements, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

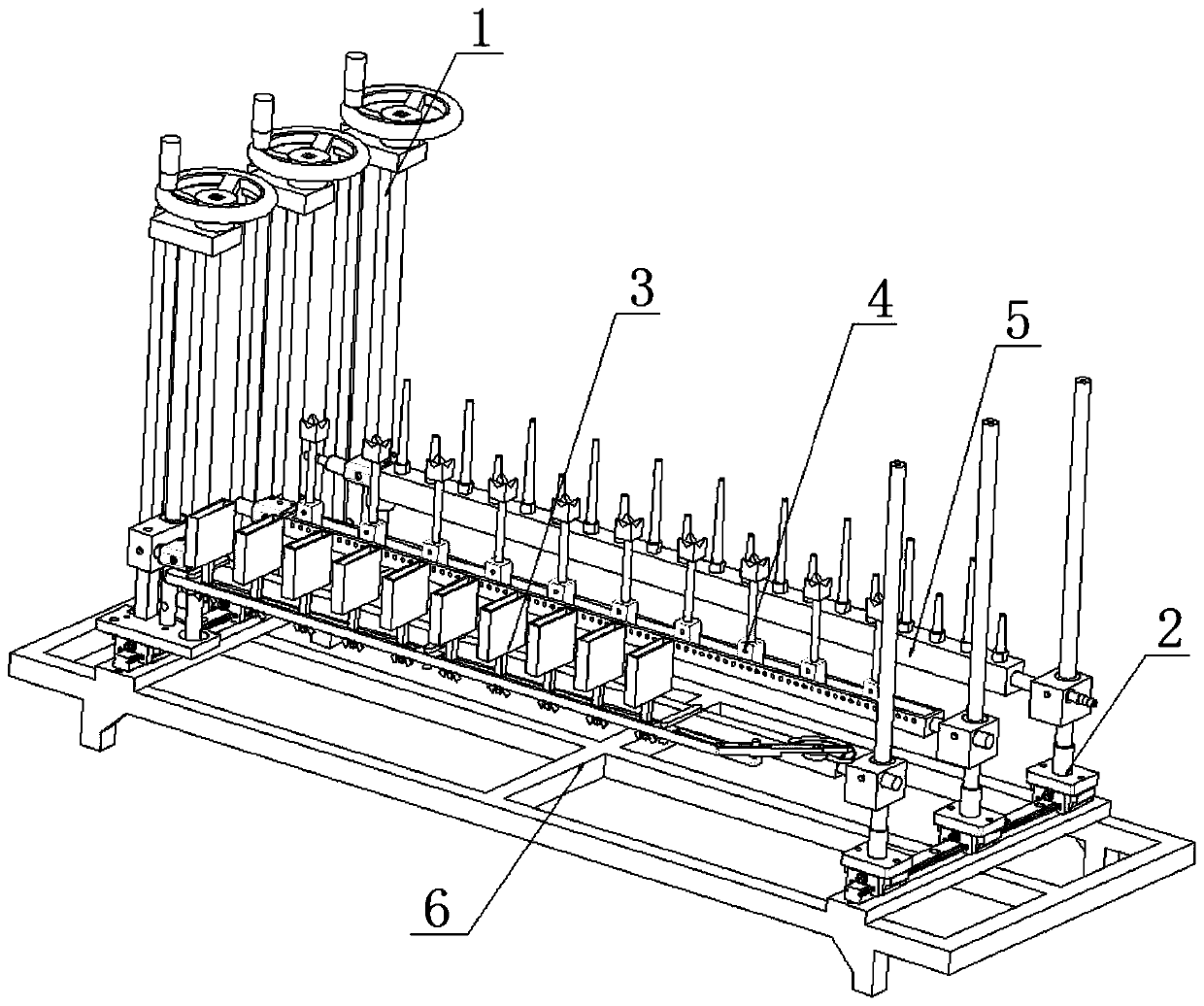

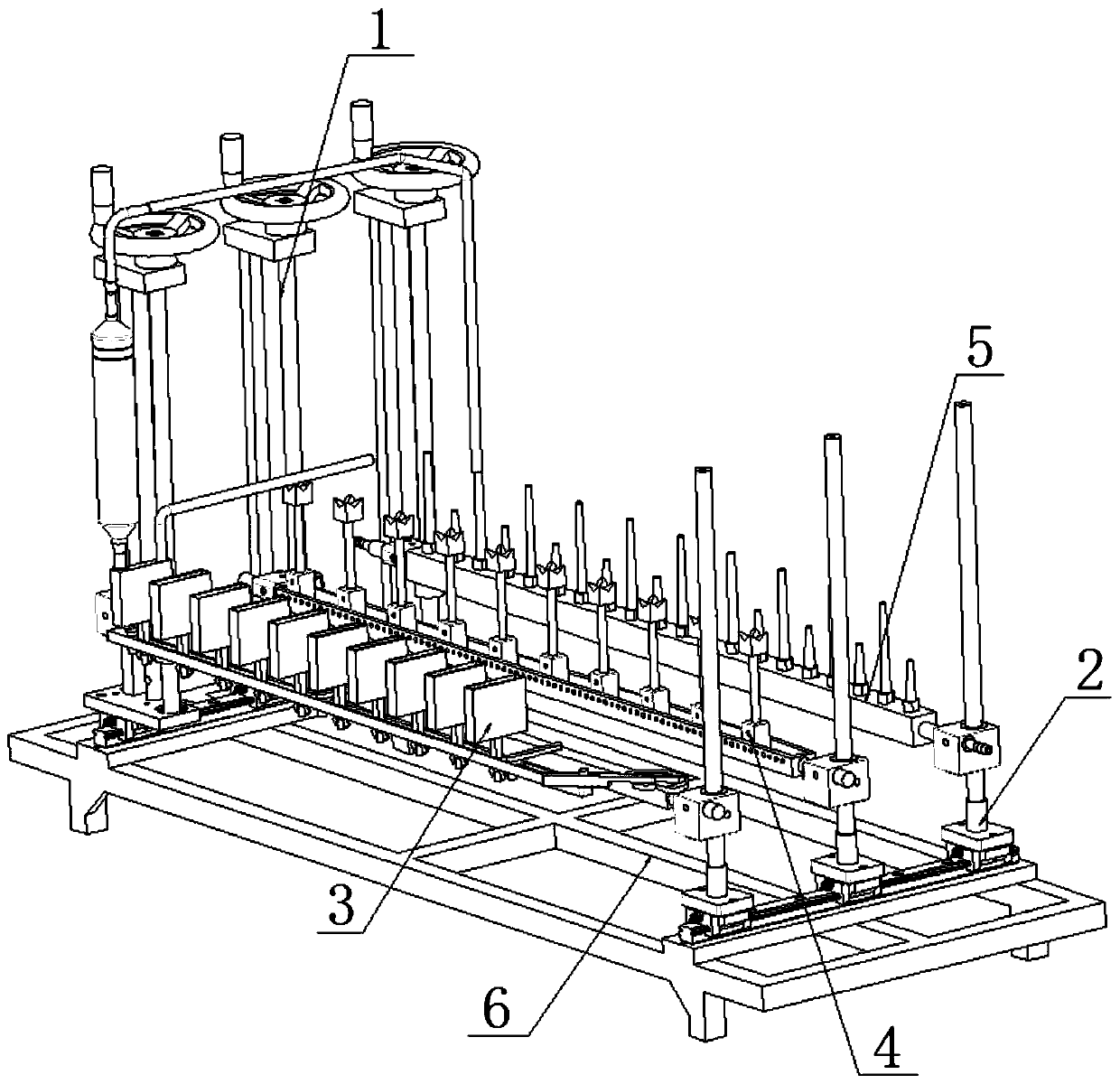

[0031] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix Figure 1-9 , understanding of the present invention.

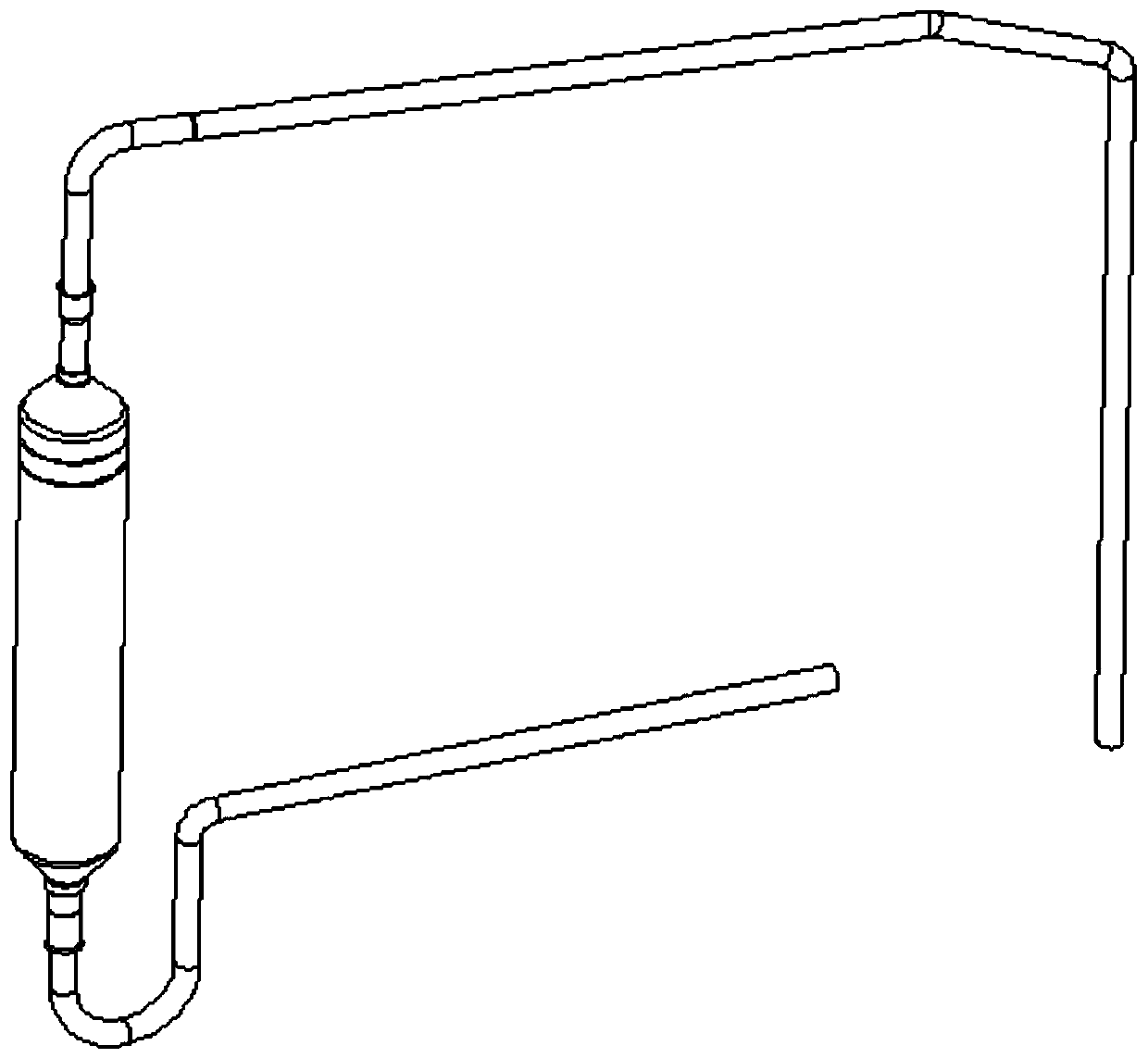

[0032] The pipe fittings of the existing cooling heat exchange system of the room air conditioner need to be combined and welded by multiple pipe fittings to be integrated, and the requirements such as direction, angle, position, height, etc. between the pipe fitting connections cannot be realized. Such as figure 2 It is the parts diagram of the pipe fittings. The invention created by the invention can quickly fix the height and position the welding of each sub-pipe through combined lifting, adjusting and positioning, so as to ensure that the parameters and indicators of the pipe fittings meet the requirements after forming. Multi-station welding can improve Welding efficiency and welding quality, standardization of on-site operations, saving device costs, and improving generalization rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com