Machining method for connecting parts of segmented machine frames of marine diesel engine

A technology of marine diesel engine and processing method, which is applied to the processing of the connecting parts of the marine diesel engine segmented frame and the processing of diesel engine parts, can solve the problems of high processing difficulty, processing deformation, difficult control of shape and position difference, etc. Simple and convenient operation, high-precision processing, and the effect of controlling the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

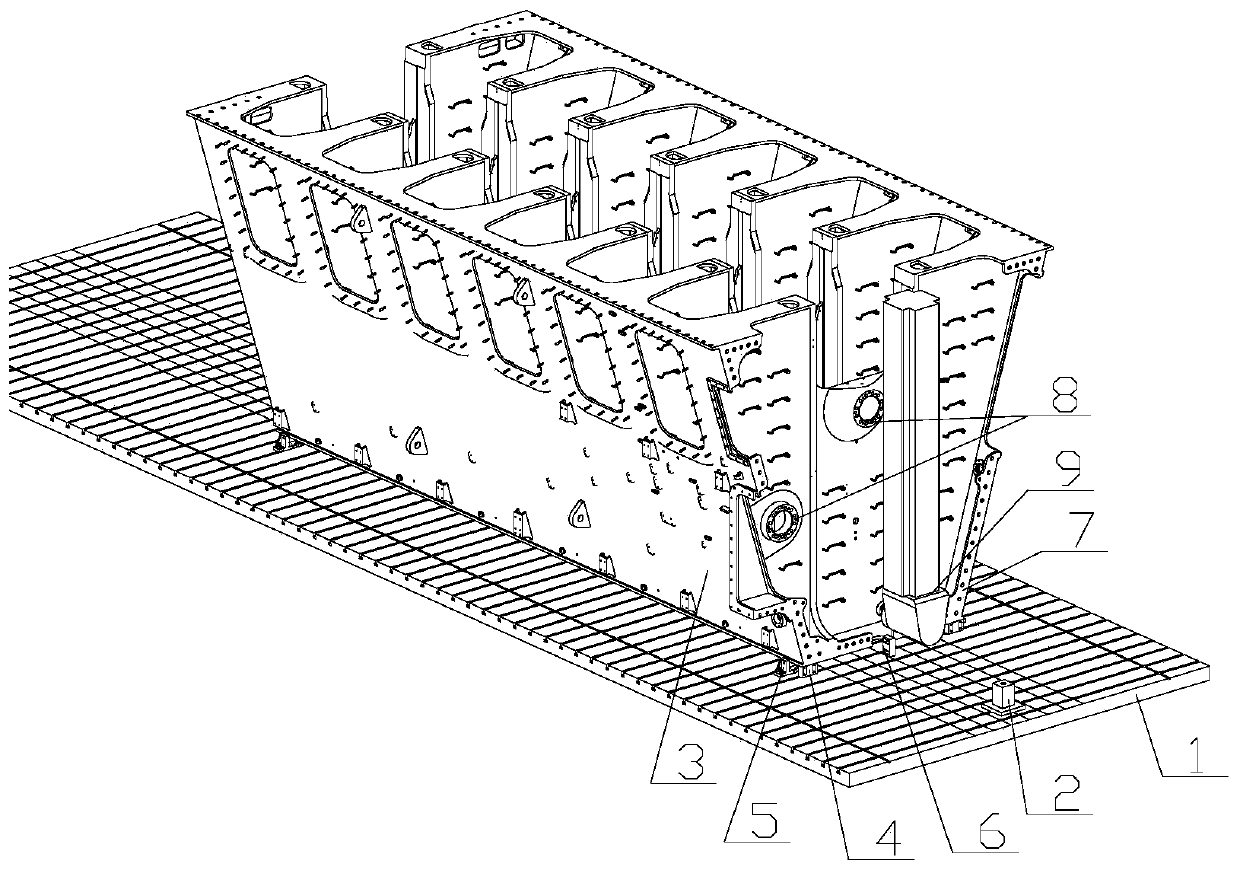

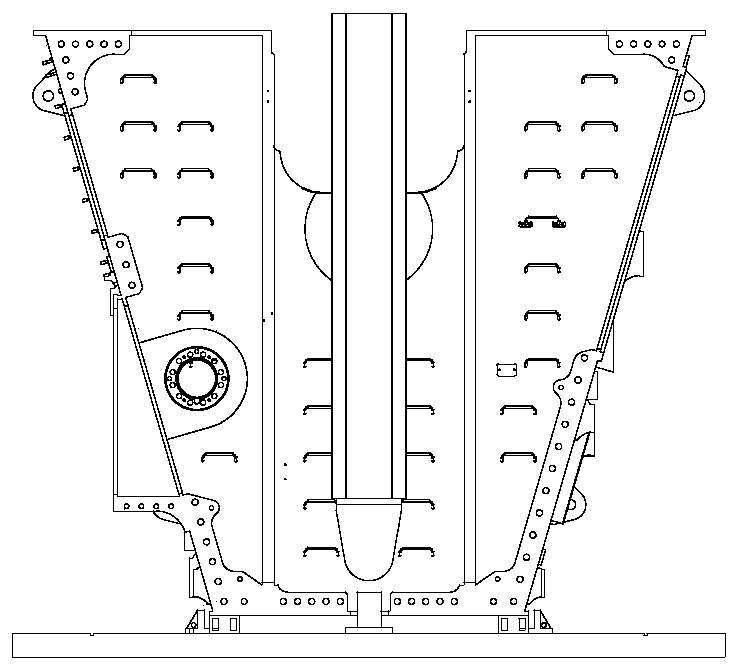

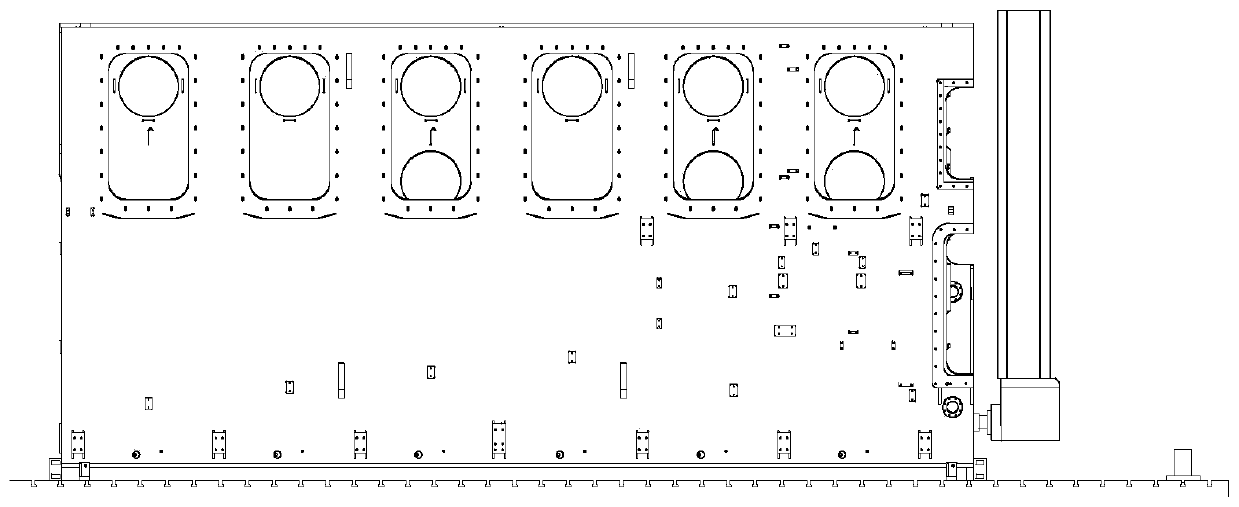

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples, but the protection scope of the present invention cannot be limited by this.

[0032] The processing method of the segmented frame connection part of the marine diesel engine of the present invention comprises:

[0033] Delineate the X, Y, Z coordinate reference line, the center line of the frame and the margin lines for the segmented frame blank; the adjustable cushion block, support backer, correction block and reference conversion tool setting block on the gantry milling machine table are set The connecting surface of the front section frame and the rear section of the frame faces the gantry and puts it upside down on the car, and the connection surface is processed through the calibration and setting of the adjustable pad, the support, the calibration block and the reference conversion tool setting block. ;The connecting surfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com