Novel electric hammer

An electric hammer, a new type of technology, applied in the direction of impact tools, light impact tools, manufacturing tools, etc., can solve the problems of easy oil leakage, high noise, and low drilling rate of the casing, and achieve high performance utilization of magnetic steel. The overall performance is improved and the production process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

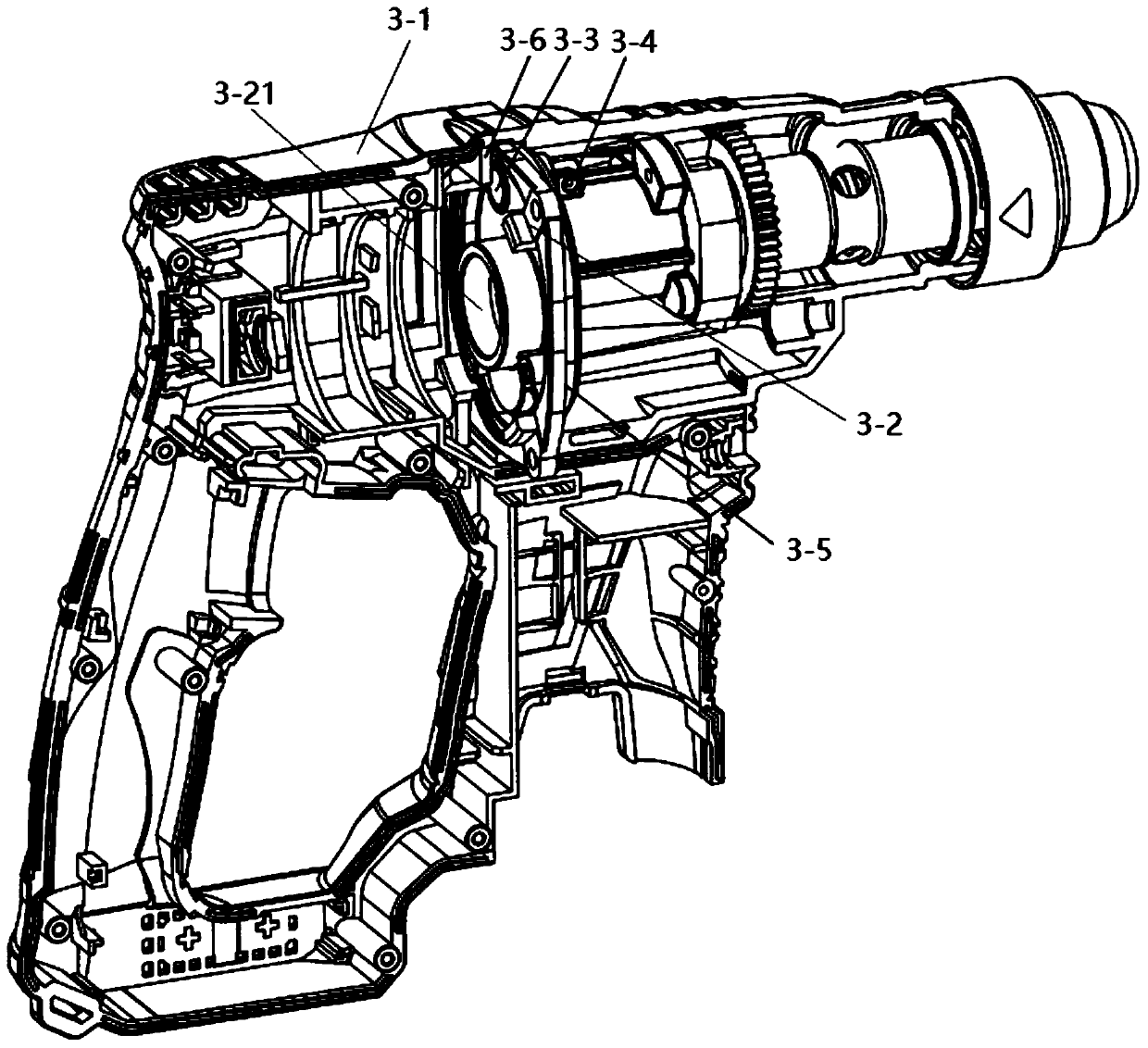

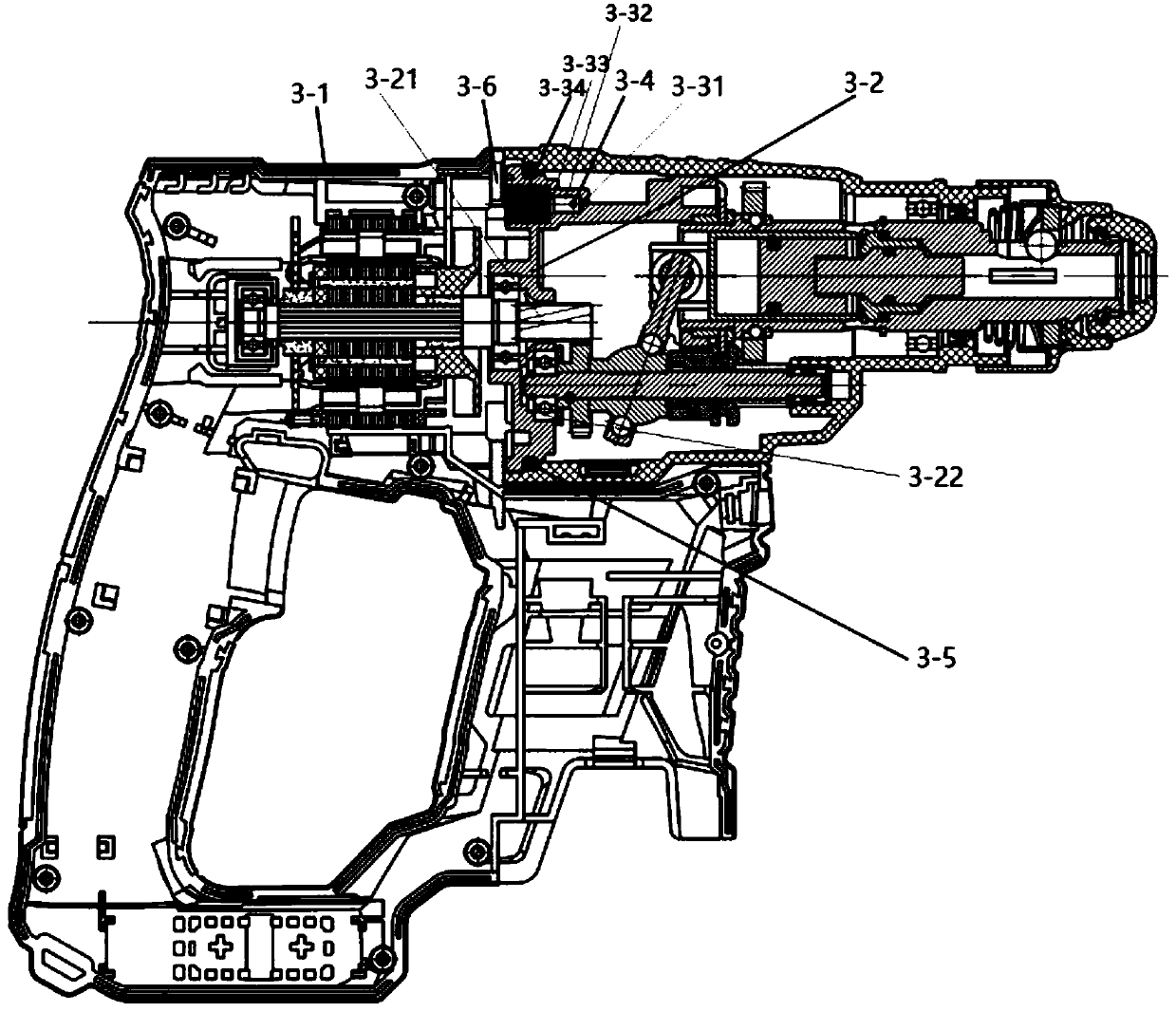

[0051] Such as figure 1 , figure 2 As shown, a new type of electric hammer includes a power tool body 3-1, a bracket 3-2, a swing rod bearing transmission structure, a brushless motor 1-7 and a battery assembly; the bracket is arranged inside the power tool body 3-1, without The brush motor 1-7 and the battery assembly are respectively arranged on both sides of the bracket; a through hole is set in the middle of the bracket for the gear of the brushless motor 1-7 to pass through, and a placement hole 3-22 is set below the through hole for the swing rod bearing transmission structure Pass; the drive structure of the swing rod bearing is meshed with the brushless motor 1-7.

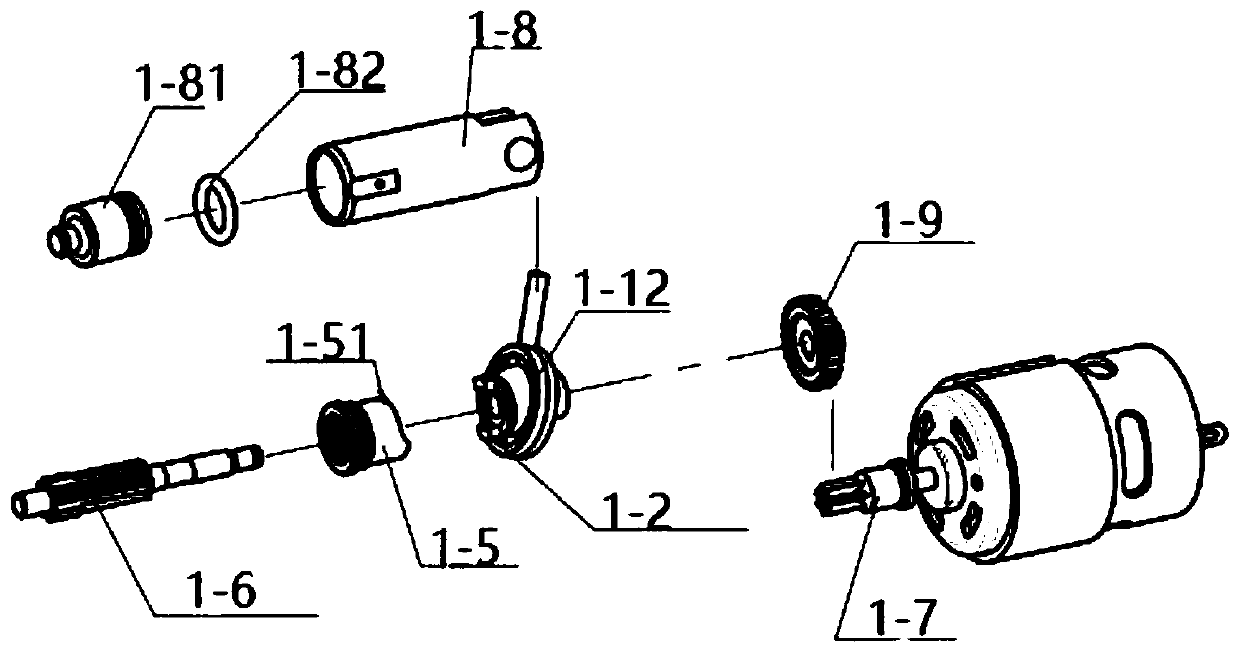

[0052] The specific swing rod bearing transmission structure, such as Figure 3-Figure 9 Shown, comprise fork bearing, clutch 1-5, intermediate shaft 1-6 cylinder 1-8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com