Automatic sleeving machine for lead-acid battery panel calandria

A technology of lead-acid batteries and plate tubes, applied in the direction of lead-acid batteries, lead-acid battery electrodes, lead-acid battery construction, etc., can solve the problems of large differences in manual operations, large labor occupation, and harsh working environments, and achieve Quick and reliable clamping, less labor occupation, and improved working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

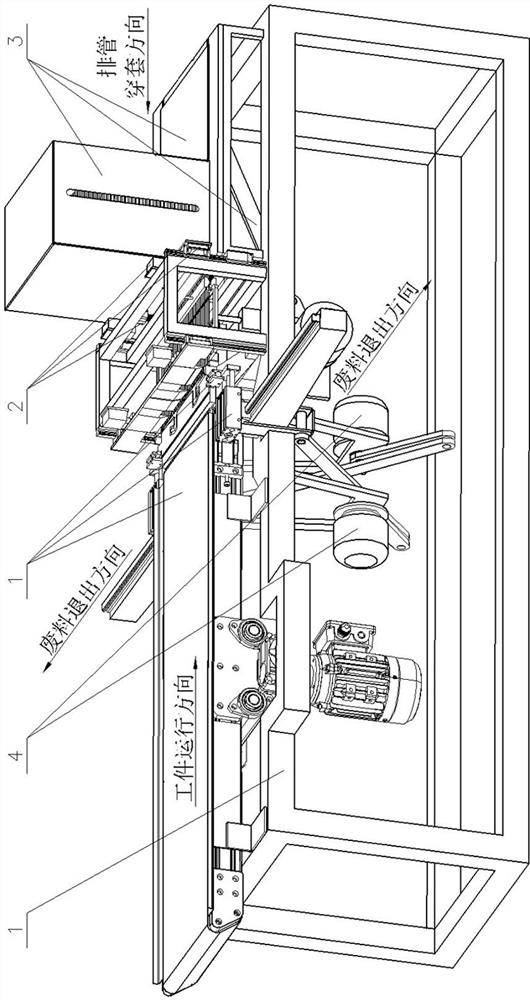

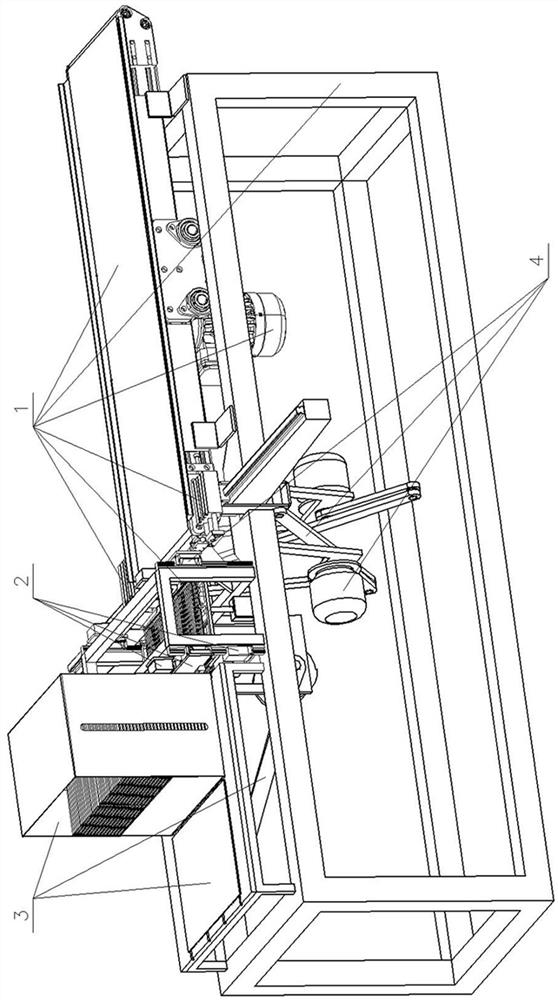

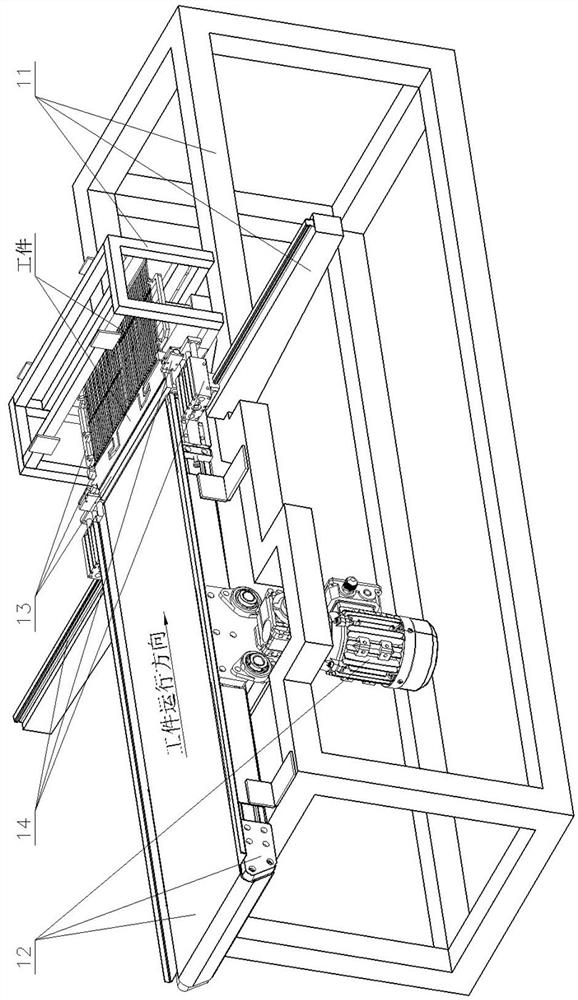

[0064] 1. Conveying and clamping device 11, frame 110, underframe 111, outrigger I 112, U-shaped frame I 113, beam 114, longitudinal beam 115, installation plate I 116, installation plate II 117, support plate 12, conveying device 121. Conveying frame 1210, rectangular frame 1211, supporting plate 1212, limiting plate 1213, right-angle support plate 1214, adjusting block 1215, screw 1216, nut 1217, chute 122, conveying driving device 1221, driving plate 1222, driving roller 1223 , Conveying drive motor 1224, pressure roller 123, reversing assembly 1231, reversing plate 1232, reversing roller 124, tensioning assembly 1241, tensioning plate 125, conveyor belt 13, positioning device 131, positioning plate 1311, lug I 132, Bracket Cylinder 133, Bracket 1331, Lug II 14, Clamping Device 141, Returning Guide Rail 142, Returning Slider 143, Clamping Cylinder 144, Clamping Plate 145, Finger Cylinder 1451, Clamping Finger 2 , comb straight and end cutting device 21, comb straight device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com