Equipment for implanting grating optical fiber sensor into steel strand cable body

A technology of sensor equipment and grating optical fiber, applied in the field of steel strand wire body implanted grating optical fiber sensor equipment, can solve the problems of drilling deviation, easy deviation, drilling precision drilling verticality deviation, etc., so as to reduce torsion The probability of phenomenon, the improvement of forming accuracy, the effect of improving the slotting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

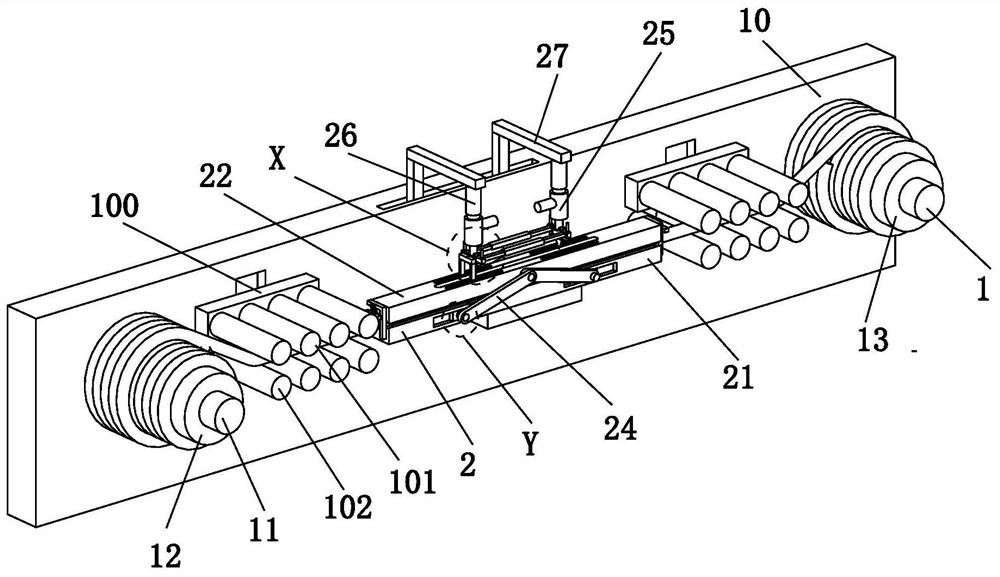

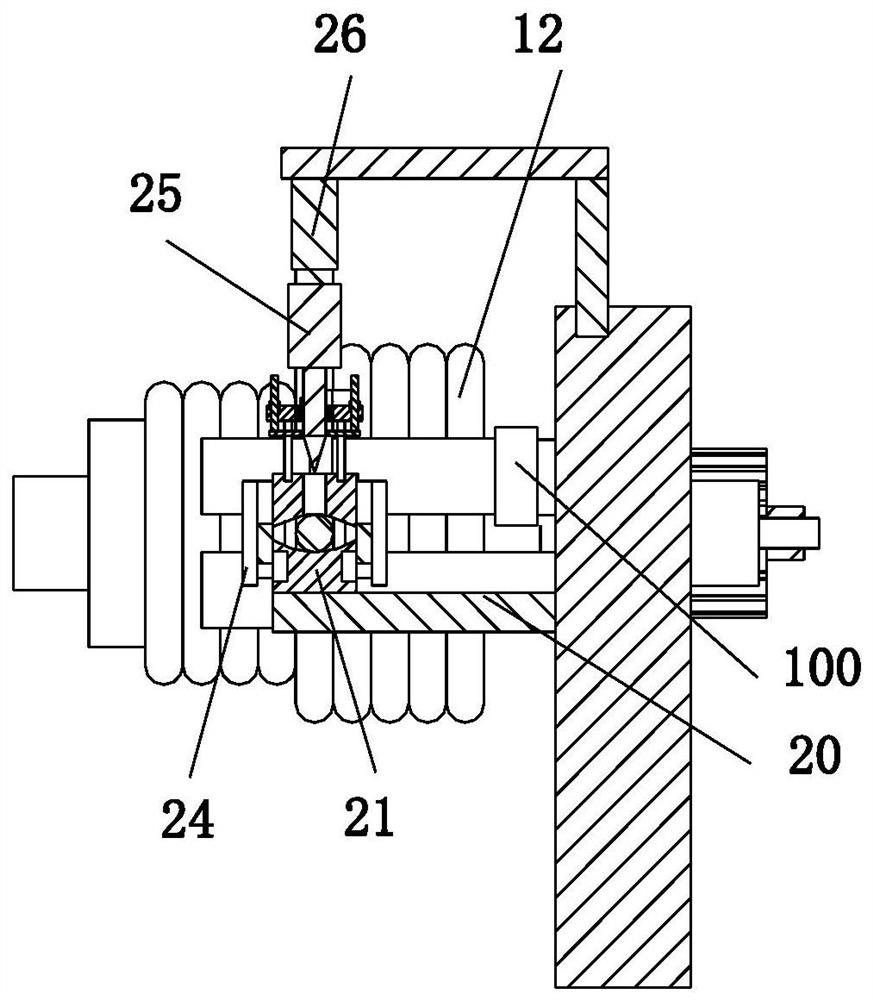

[0039] like Figure 1 to Figure 9 As shown in the figure, a steel strand cable body is implanted into a grating optical fiber sensor device, including a winding mechanism 1 and a clamping mechanism 2. The lower end of the winding mechanism 1 is installed on the existing working ground, and the winding mechanism 1 The middle of the front end is provided with a clamping mechanism 2 .

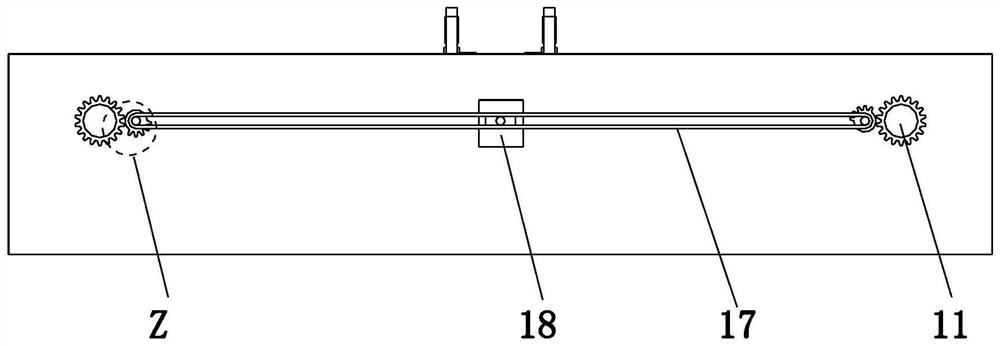

[0040] The winding mechanism 1 includes a vertical frame 10, an installation shaft 11, a coil 12, a winding core 13, a main gear 14, a shaft rod 15, an incomplete gear 16, a belt 17 and a motor 18. The lower end surface of the vertical frame 10 Installed on the existing working ground, the left and right ends of the vertical frame 10 are symmetrically installed with installation shafts 11 through bearings. The front end of the 11 is installed with the winding core 13 by screwing, and the rear end of the installation shaft 11 is installed with the main gear 14. The main gear 14 is located on the r...

Embodiment 2

[0050] On the basis of Embodiment 1, when the electric slider 23 slightly loosens the wire body of the steel strand between the upper clamping block 22 and the lower clamping block 21, the wire body of the steel strand is rotated 180 degrees by the existing equipment or manually, according to the implementation In the operation steps of Example 1, re-drilling processing and implantation operation are performed to realize the implantation operation function of two grating optical fiber sensors.

Embodiment 3

[0052] On the basis of the first embodiment, when the electric slider 23 slightly loosens the wire body of the steel strand between the upper clamping block 22 and the lower clamping block 21, the wire body of the steel strand is rotated by 120 degrees through the existing equipment or manually, according to the implementation The operation steps of Example 1 are to drill again and implant the spraying operation. After the second optical grating optical sensor is implanted and sprayed, the operation is performed again according to the above steps to realize the implantation operation function of the three optical grating optical sensors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com