Machining method for grooving of shaft workpiece

A technology for shaft workpieces and processing methods, which is applied in the field of grooving processing of shaft workpieces, can solve problems such as low processing efficiency, poor consistency, and difficult control of processing accuracy, and achieve improved processing efficiency, simple and convenient operation, and mobile feed high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The present invention will be further described below in conjunction with the drawings and embodiments.

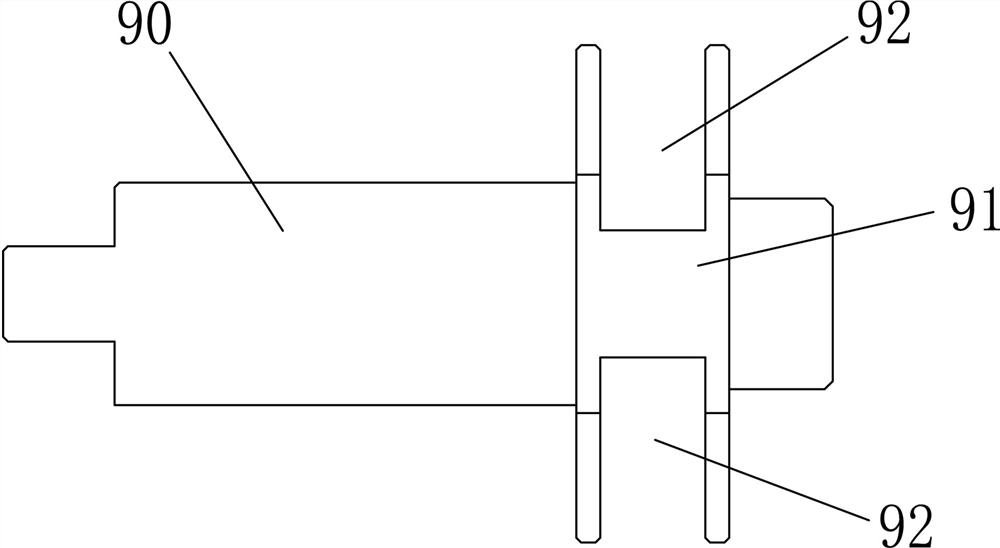

[0024]Such asfigure 1 The shown metal shaft workpiece 90 has a boss portion provided on its peripheral surface. The boss portion has symmetrical cutting planes 91 on its front and back sides, and the boss portion has symmetrical cutting grooves 92 on its upper and lower sides. The processing method of this embodiment is to process the groove 92 of the shaft workpiece 90.

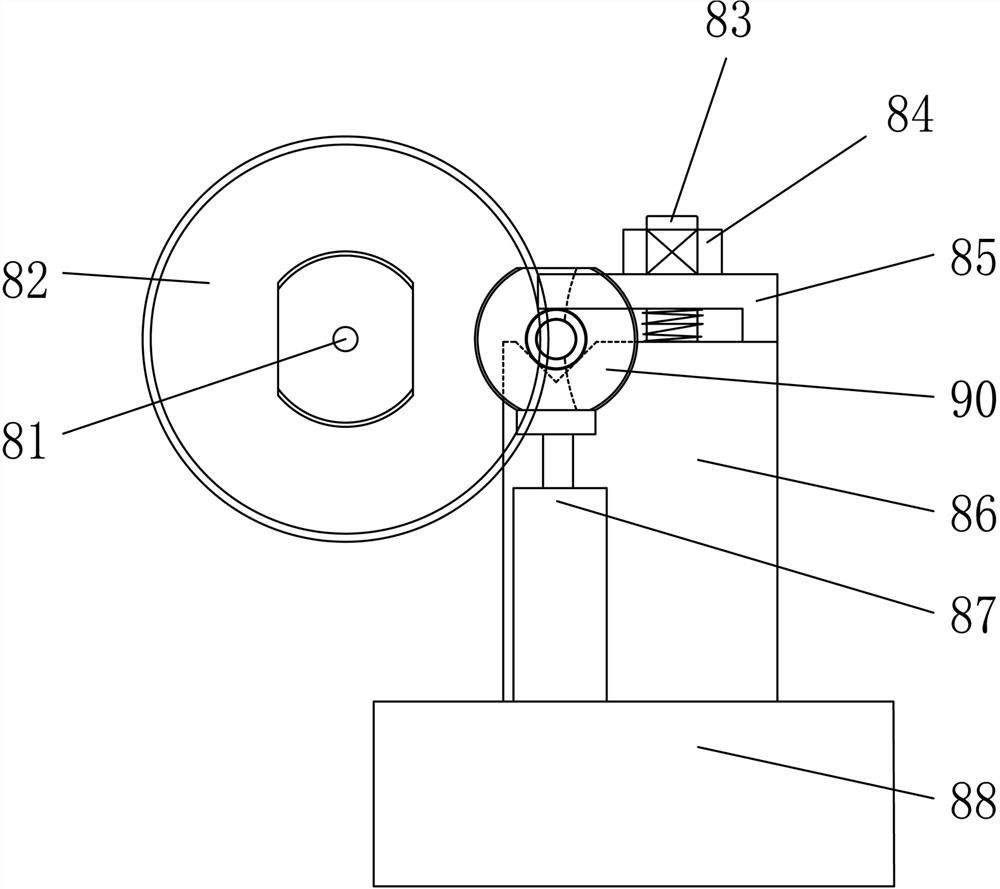

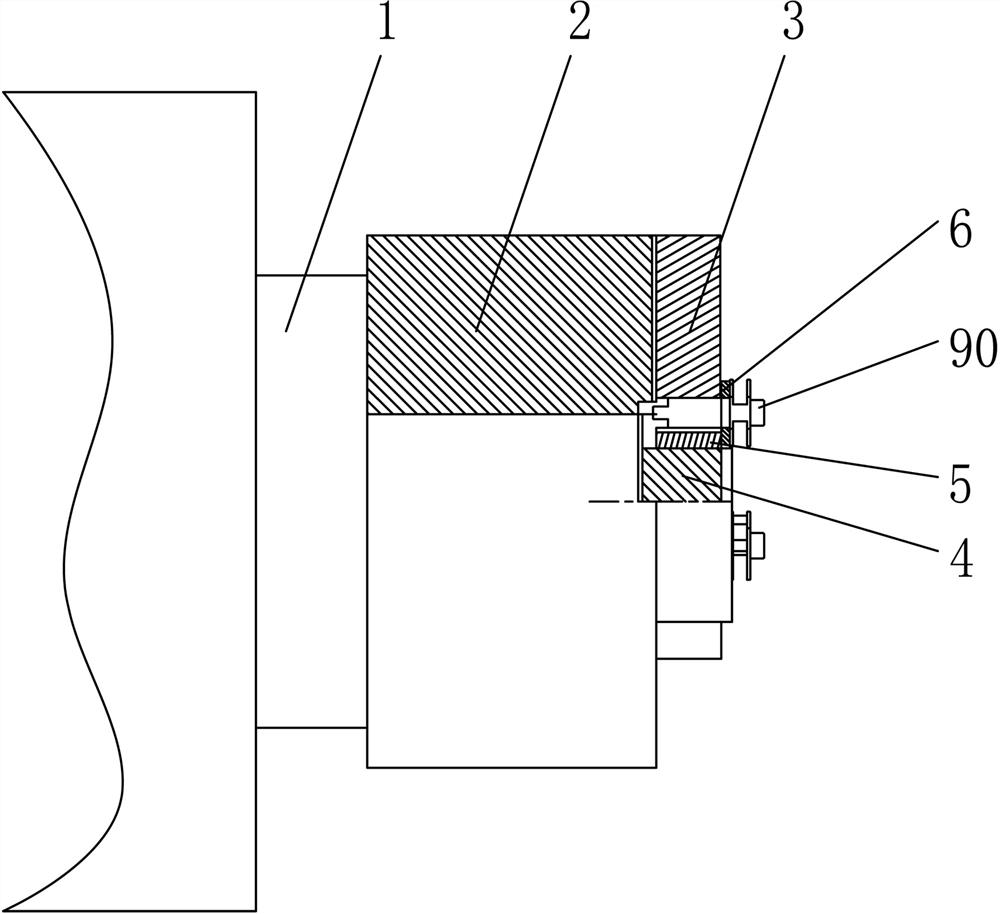

[0025]Seeimage 3 ,Figure 4 withFigure 5 , The processing device of this example includes a main shaft 1, the main shaft 1 is provided with a hydraulic three-jaw chuck 2, the hydraulic three-jaw chuck 2 is connected with three coaxially adjustable clamping claws 3, the clamping claws 3 through the first hexagon socket screw 11 is fixedly connected with the hydraulic three-jaw chuck 2. The hydraulic three-jaw chuck 2 is provided with a screw hole for screwing with the first hexagon socket screw 11, and the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com