Charging pile efficiency optimization module scheduling method

A scheduling method and charging pile technology, applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems of low module work efficiency, large module power loss, unreasonable even distribution of power modules, etc., to reduce work efficiency Low, best utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

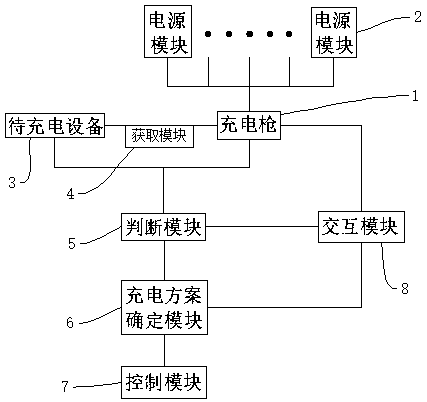

[0045] like figure 1 and figure 2 As shown, a method for optimal module scheduling of charging pile efficiency, the charging pile includes at least one charging gun 1, and the at least one charging gun 1 is configured to output the electric energy of at least one power supply module 2, and the method includes:

[0046] Receive a charging request from the device 3 to be charged, and the charging request includes the required voltage Un and the required current In of the device 3 to be charged;

[0047] Acquiring power output efficiency information of at least one power module 2;

[0048] Based on the charging request of the device to be charged 3 and the power output efficiency information of at least one power supply module 2, a charging scheme under the current charging request is determined, and the charging scheme at least includes the number of power supply modules 2 put into operation and the output current of each power supply module 2. I and output voltage U;

[004...

specific Embodiment 1

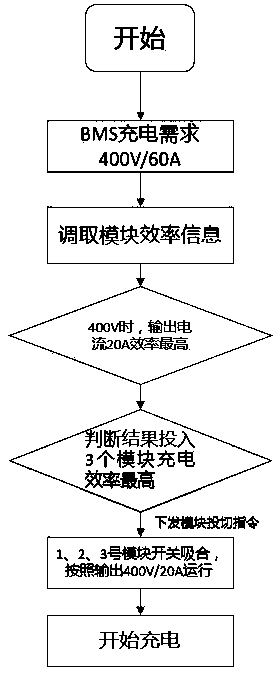

[0071] like image 3 As shown, this charging pile contains eight 15kW charging modules of the same brand.

[0072] Step 1: Connect the electric vehicle to the charging pile;

[0073] Step 2: The charging pile reads the charging requirements and charges at 400V / 60A;

[0074] Step 3: The charging pile retrieves the module efficiency curve;

[0075] Step 4: Judging that the module output current is 20A under the condition of 400V, the efficiency is the highest;

[0076] Step 5: Issue the module switching instruction, put the modules numbered 1, 2, and 3 into work, and the working current is 20A;

[0077] Step 6: The switches of modules 1, 2, and 3 are closed and charging starts.

specific Embodiment 2

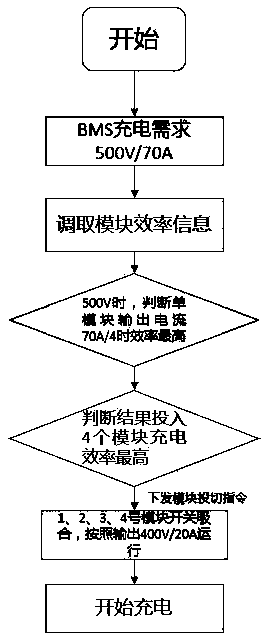

[0079] like Figure 4 As shown, this charging pile contains eight 15kW charging modules of the same brand.

[0080] Step 1: Connect the electric vehicle to the charging pile;

[0081] Step 2: The charging pile reads the charging requirements and charges at 500V / 70A;

[0082] Step 3: The charging pile retrieves the module efficiency curve;

[0083] Step 4: Take m as an integer, and 1≤m≤8, when it is judged that the output current of a single module is 70A, the output efficiency of the module is the highest;

[0084] Step 5: judge m to be 4;

[0085] Step 6: Issue the module switching instruction, put the modules numbered 1, 2, 3, and 4 into operation, and the working current is 17.5A;

[0086] Step 7: The switches of modules 1, 2, 3, and 4 are pulled in and charging starts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com