A kind of hydrophobically associated anionic polyacrylamide water-in-oil emulsion and preparation method thereof

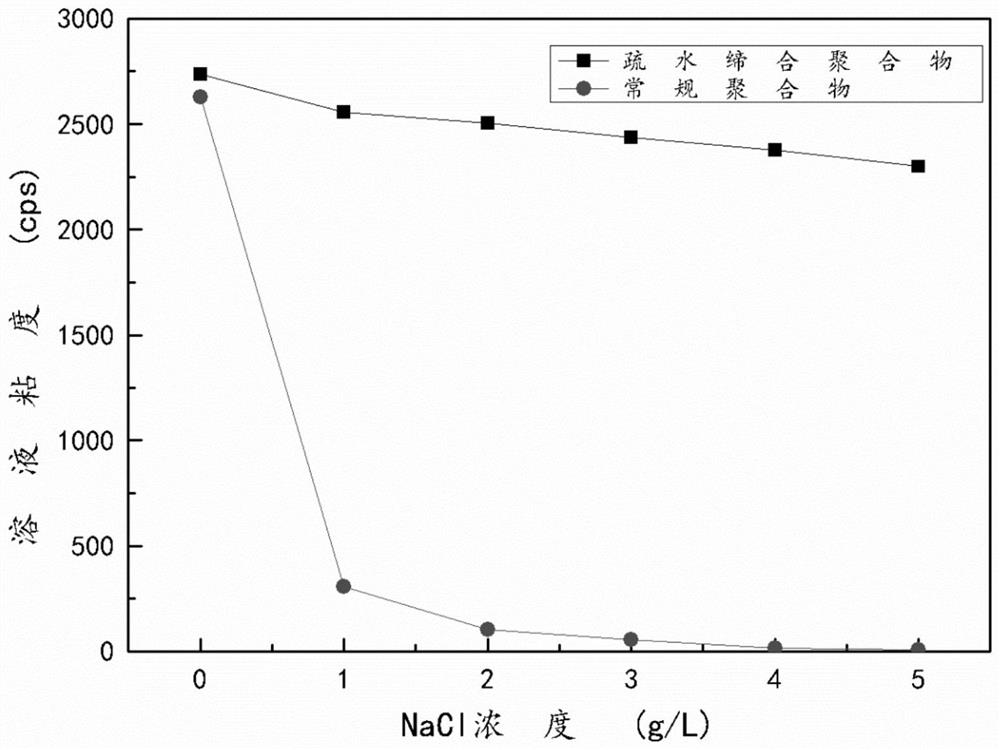

A technology of polyacrylamide and water-in-oil emulsion, which is used in the preparation of hydrophobically associated anionic polyacrylamide water-in-oil emulsion and the field of water emulsion, can solve the problem of low association of hydrophobic groups, large energy consumption and slow dissolution rate and other problems, to achieve the effect of good stability, improved shear resistance and salt resistance, and fast dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Dissolve 6g of emulsifier T81 (emulsifier A, accounting for 15% of the total amount of emulsifier) in 100g of deionized water, stir evenly, and then add 17.5g of styrene (hydrophobic monomer, accounting for 5% of the total amount of monomer) dropwise , then stirred at high speed for 30min, then added 122.5g of solid acrylamide, 420g of anionic monomer ammonium acrylate aqueous solution (the mass concentration of anionic monomer is 50%, accounting for 60% of the total amount of monomers), 10g of EDTA with a mass concentration of 5%. -2Na aqueous solution (complexing agent), 0.5g mass concentration of 1% tert-butyl hydroperoxide aqueous solution (water-soluble oxidizing agent) and 15g urea (dissolution accelerator), stirring and dissolving, adjusting pH to 7.2, replenishing water to 700g, Then stir at high speed for 30 minutes to make an aqueous phase solution;

[0050] 10g emulsifier S80 (emulsifier B) and 24g emulsifier T81 were dissolved in 262g D80 solvent oil to ma...

Embodiment 2

[0055] Dissolve 5g of emulsifier Atlas G-1096 (emulsifier A) in 100g of deionized water, stir well, then add 17.5g of hexadecyl (meth)acrylate (hydrophobic monomer) dropwise, and stir at high speed for 30min , then successively add 122.5g solid acrylamide, 420g anionic monomer sodium acrylate aqueous solution (the mass concentration of anionic monomer is 50%), 10g mass concentration is 5% EDTA-2Na aqueous solution (complexing agent), 1g mass concentration is 1% potassium bromate aqueous solution (water-soluble oxidant) and 15g urea (dissolution accelerator), stirring and dissolving, adjusting the pH to 7.5, replenishing water to 700g, and then stirring at high speed for 30min to make an aqueous phase solution;

[0056] Dissolve 13g emulsifier HYPERMER-1038SF (emulsifier B) and 22g emulsifier Atlas G-1096 in a mixed solvent oil of 262g D80 and 5# oil to make an oil phase solution;

[0057] Add the prepared water-phase solution dropwise to the oil-phase solution, and stir at hig...

Embodiment 3

[0061] Dissolve 6g of emulsifier Atlas G-2116 (emulsifier A) in 100g of deionized water, stir evenly, then add 17.5g of dodecafluoroheptyl (meth)acrylate (hydrophobic monomer) dropwise, and stir at high speed for 30min , then successively add 122.5g solid acrylamide, 420g anionic monomer ammonium methacrylate aqueous solution (the mass concentration of anionic monomer is 50%), 10g mass concentration is 5% EDTA-2Na aqueous solution (complexing agent), 1g mass concentration Concentration is 1% potassium bromate aqueous solution (water-soluble oxidant) and 15g urea (dissolution accelerator), stirring and dissolving, adjusting pH to 7, replenishing water to 700g, and then stirring at high speed for 30min to make an aqueous phase solution;

[0062] Dissolve 14g emulsifier HYPERMER-B210 (emulsifier B) and 20g emulsifier Atlas G-2116 in 262g Isopar M white oil to make an oil phase solution;

[0063] Add the prepared aqueous phase solution dropwise to the oil phase solution, and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com