Wheel disc type false twist compact spinning device with broken-end breakpoint control function

A compact spinning and breaking point technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve problems such as increased energy consumption, different yarn forming processes, and different mechanism settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

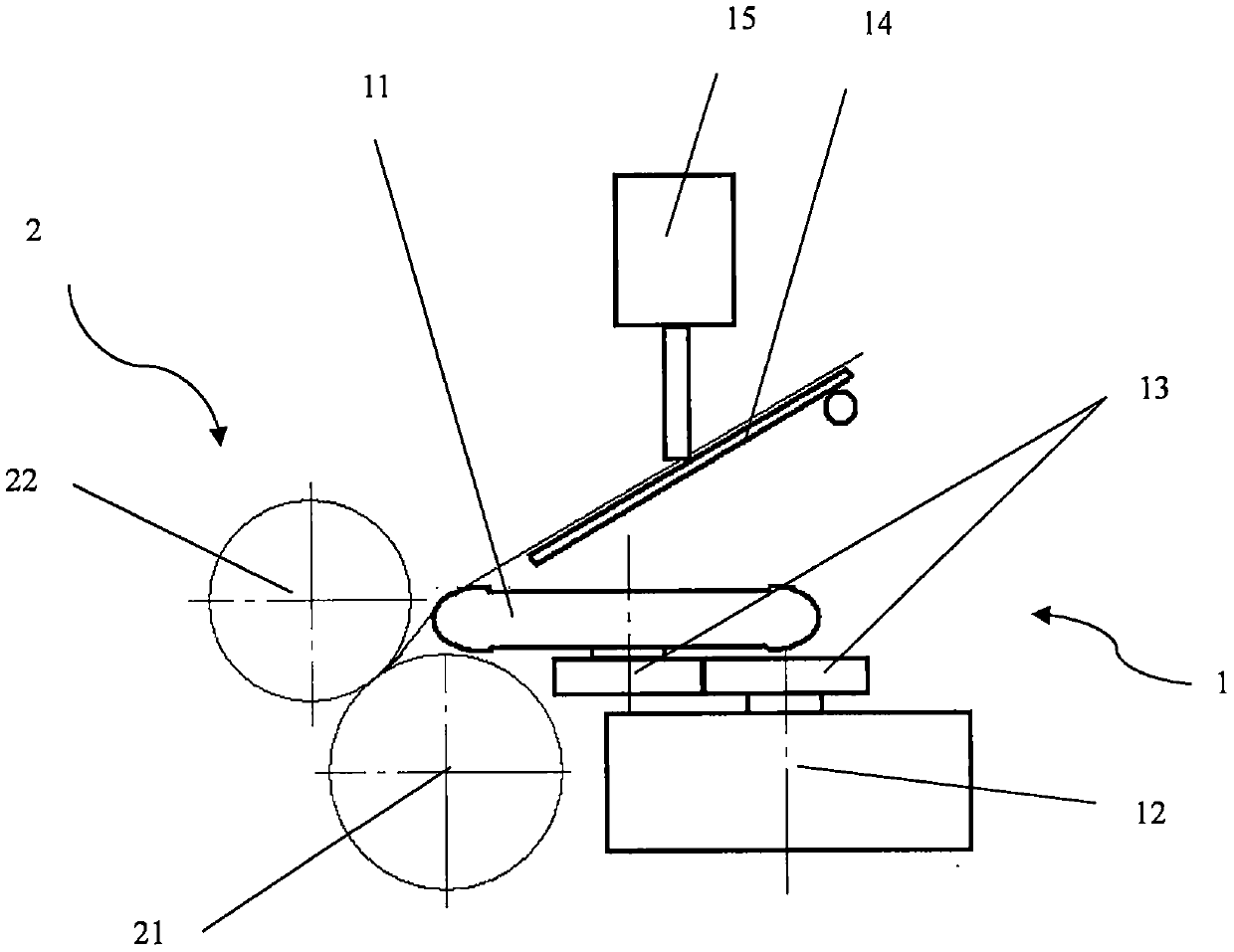

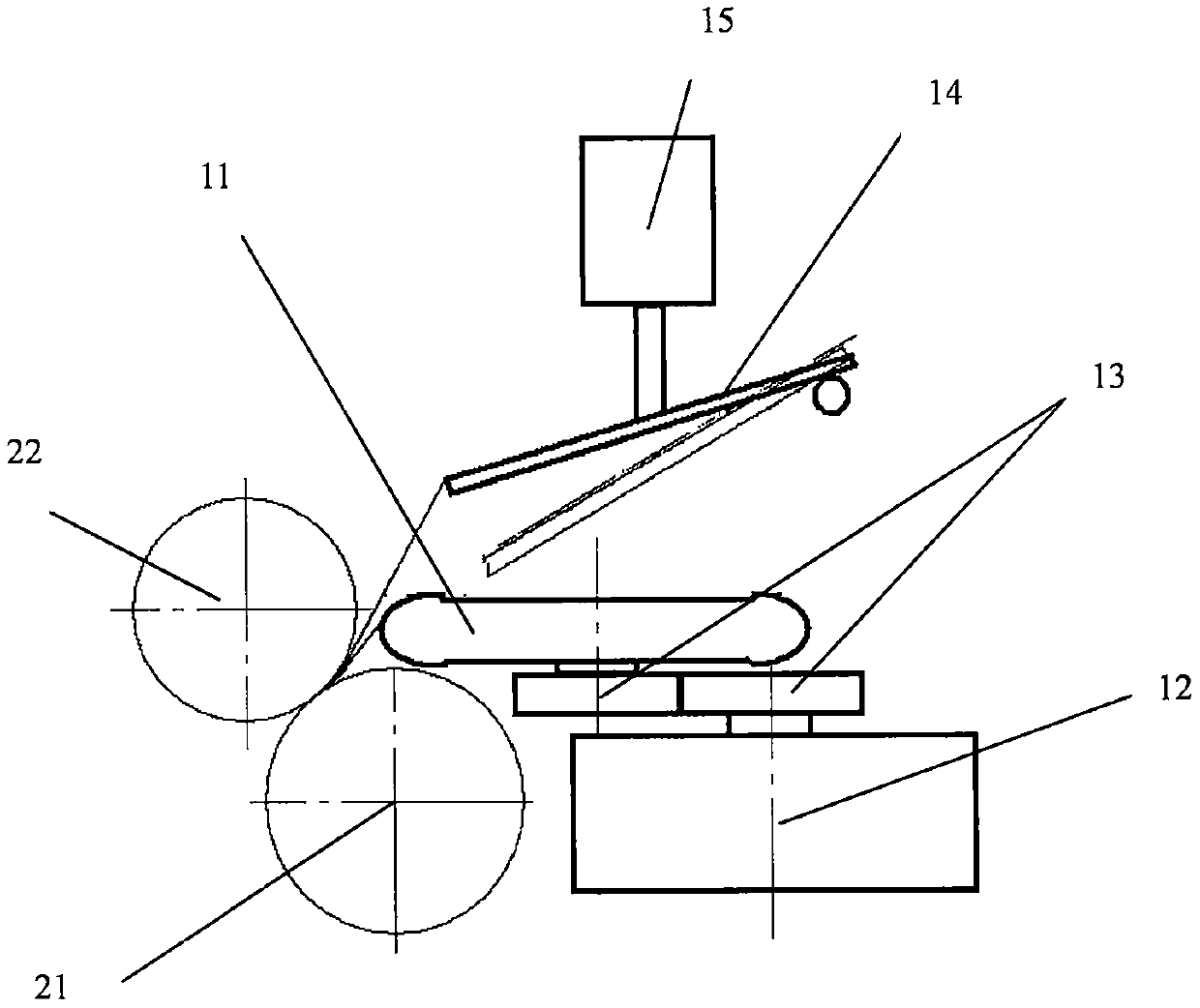

[0015] figure 1 As shown, a wheel-type false-twist compact spinning device 1 with end-break point control is located on the output side of the front roller of the drafting mechanism and the input side of the lead-out roller 2. Each spindle position includes a friction wheel 11. Transmission wheel 12, transmission gear 13, hairiness suppressor 14, breakpoint control mechanism 15, friction wheel 11 and transmission wheel 12 in the device are installed on the base, transmission wheel 12 transmits friction wheel 11 through gear 13, transmission wheel 12 is driven by a transmission belt, the edge of the friction wheel 11 is in contact with the fiber strands, and the friction drives the fiber strands to rotate to form a false twist twist. The broken end break point control mechanism 15 is to control the hairiness suppressor. signal, the breakpoint breakpoint control mechanism rotates the hairiness suppressor ( figure 2 As shown), the plane in contact with the fiber whiskers is def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com