Multifunctional wool top pressing dust sticking mechanism

A multifunctional, wool-top technology, applied in textiles and papermaking, transportation and packaging, fiber processing, etc., can solve the problems of inconvenient wool surface looseness, inconvenient adjustment of wool top tension, poor dust removal effect, etc., to protect the vacuum cleaner and enrich practical functions , Concentrated cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

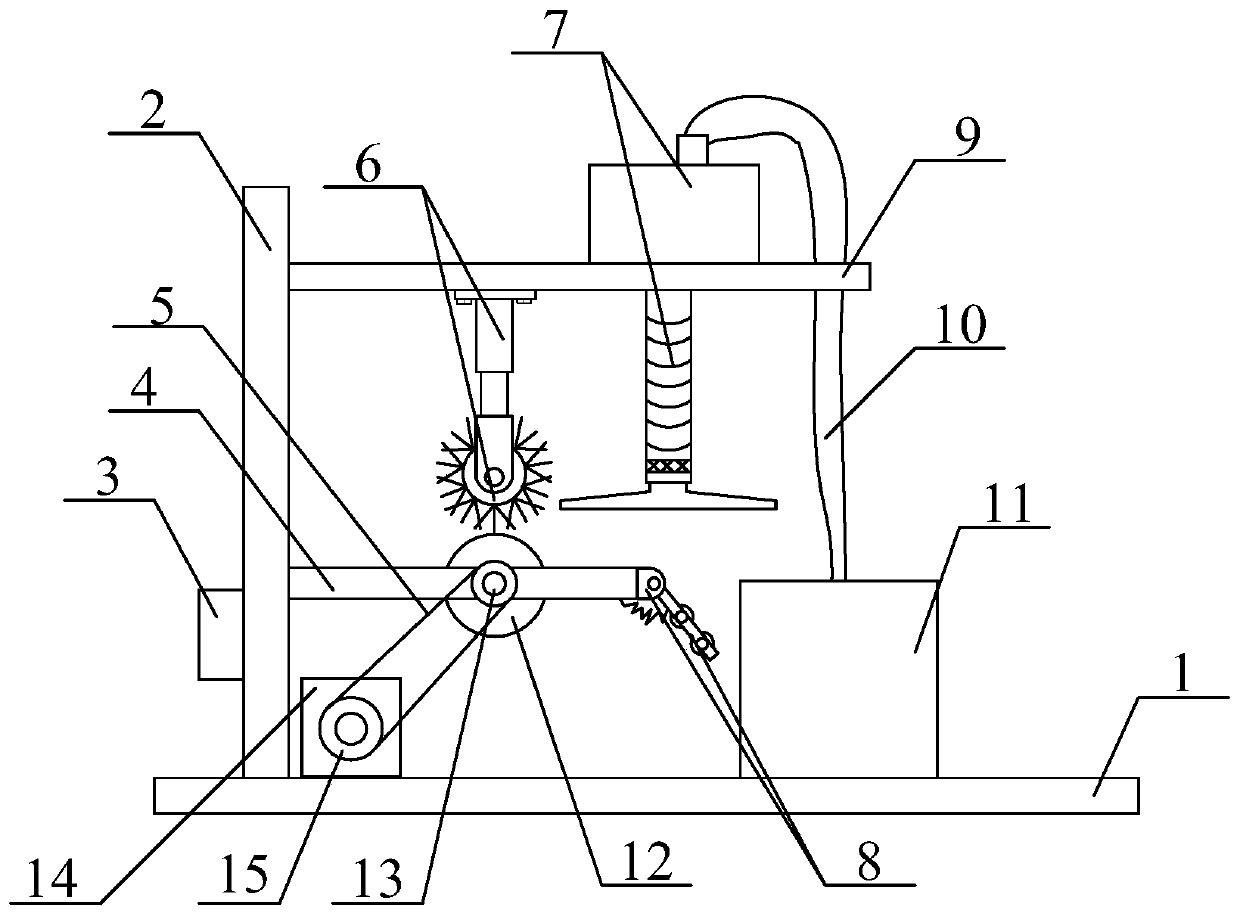

[0034] The present invention will be further described below in conjunction with accompanying drawing:

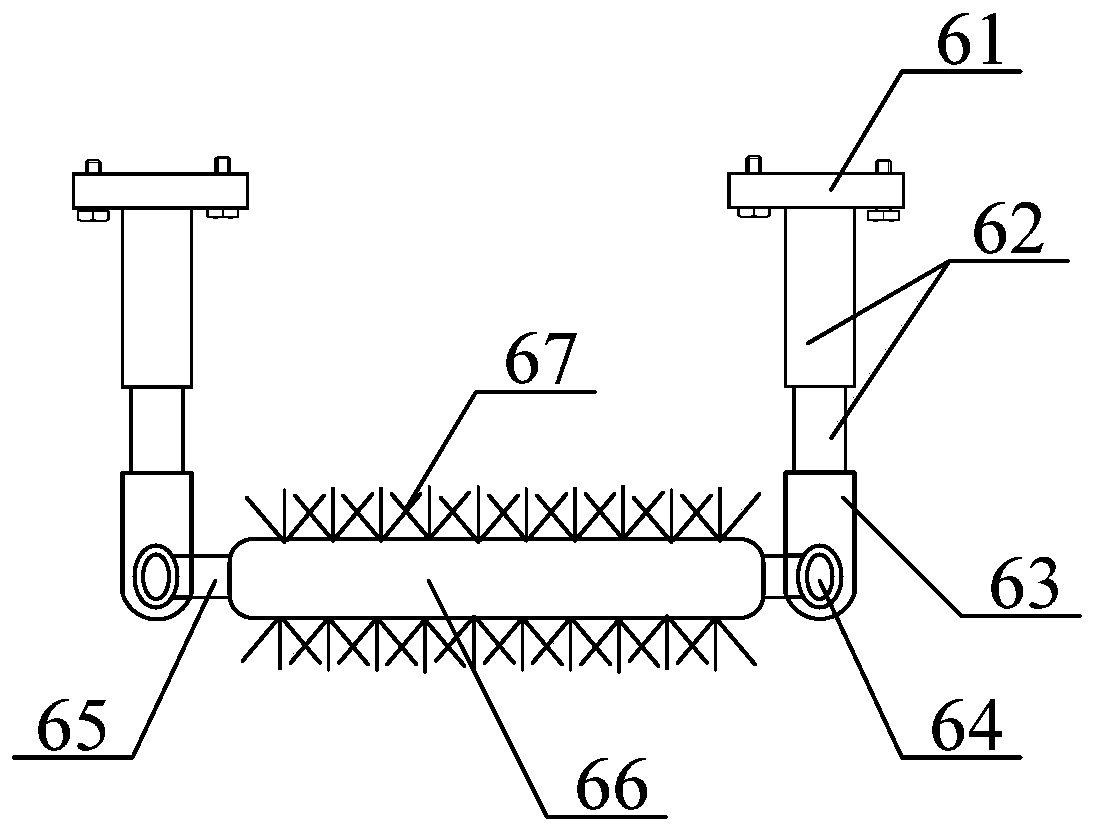

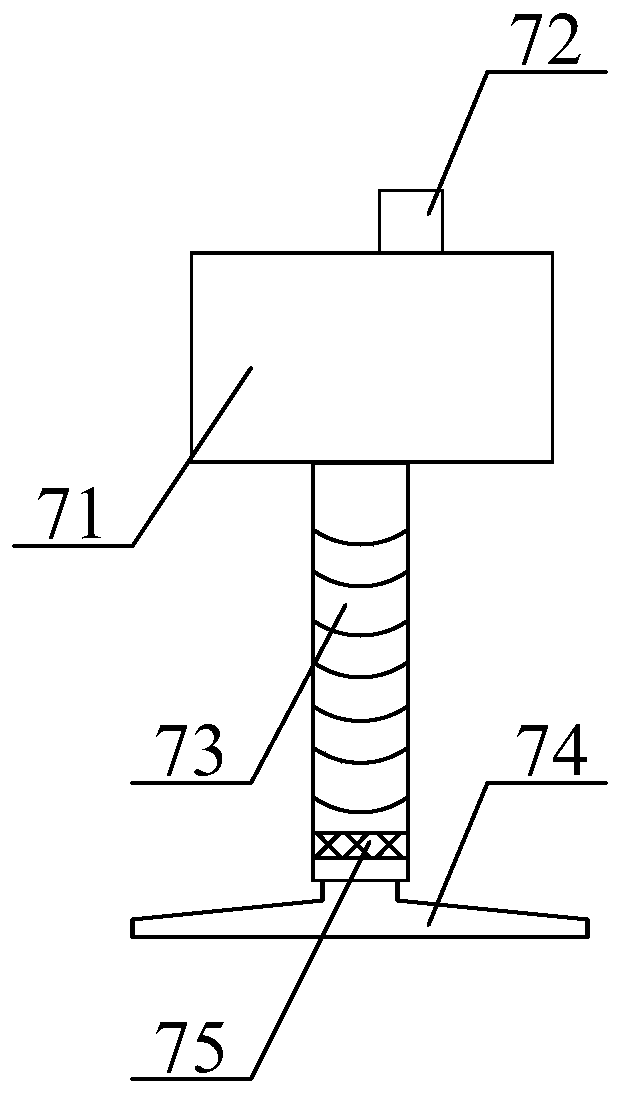

[0035] as attached figure 1 To attach figure 2As shown, the present invention provides a multi-functional wool top pressing and sticking dust mechanism, including a support base plate 1, a support column 2, a control box 3, a lower horizontal strut 4, a drive belt 5, and a structure of a wool surface loosening roller with adjustable pressure 6. Filterable dander collection pipe structure 7, wool top tension adjustment frame structure 8, upper cross support rod 9, dust guide pipe 10, storage box 11, driving roller 12, driven wheel 13, driving motor 14 and driving wheel 15, The support column 2 is bolted to the left side of the upper surface of the support base plate 1; the control box 3 is bolted to the lower left side of the support column 2; the lower horizontal strut 4 is bolted to the support The lower position on the right side of the column 2; the drive belt 5 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com