A folding bridge detection arm and detection vehicle

A bridge detection and folding technology, which is applied in bridges, bridge construction, bridge parts, etc., can solve the problems of long distance between the camera and the detection part, occlusion, detection blind area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

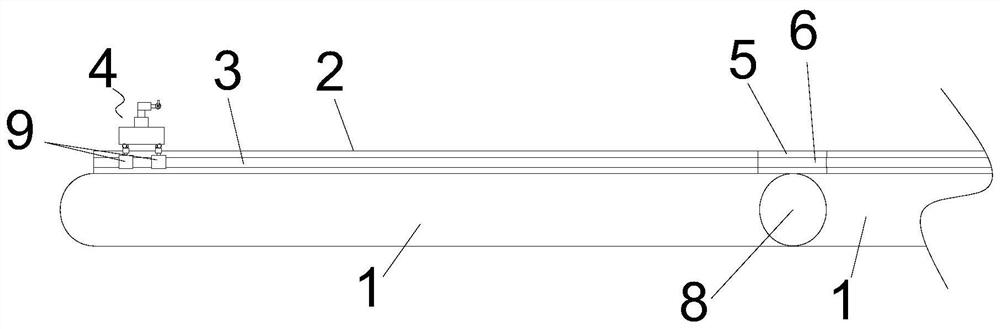

[0026] Such as Figure 3-6 A folding bridge detection arm shown includes n support arms 1 that are hingedly connected to each other, and a first slide rail 2 is fixed on the upper surface of the support arm 1; The first slide bar 3; the first slide bar 3 is slidably connected with a bridge detection device 4; the upper surface of the hinge of the first slide rail 2 is fixed with a flexible slide rail 5; the adjacent first slide rails 2 are mutually connected by the flexible slide rail 5 Connection; the flexible sliding rail 5 is formed with a second sliding bar 6 that is fixedly connected with the first sliding bar 3; the hinge of the support arm 1 is connected with a rotating mechanism 7; n≥3.

[0027] Two adjacent support arms 1 are hinged to each other through a rotating shaft 8, and one supporting arm 1 is pivotally connected to the rotating shaft 8 and is fixedly connected to the casing of the rotating mechanism 7, and the other supporting arm 1 is fixedly connected to th...

Embodiment 2

[0034] Such as Figure 7 and 8 Shown, do following improvement on the basis of embodiment 1:

[0035] On the first slide bar 3 and the flexible slide rail 5, all are fixed with some magnets 15 arranged at intervals along the N pole and the S pole in the length direction, forming the base of the linear motor; The groove pulley 9 matched with the slide bar 3 and the second slide bar 6; the groove pulley 9 is connected with the mounting seat 131, and the mounting seat 131 is connected with the linear motor mover seat 16 through the damper 13 and the torsion spring 11; The sub-base 16 is connected with a camera 20 and an illumination device 14 through an angle adjustment mechanism.

[0036] That is, in this embodiment, conventional motors are replaced by linear motors, so that the control of the operation of the bridge detection device 4 is more convenient and accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com