Cast-in-situ bored pile head stirring and crushing device

A technology for bored piles and crushing devices, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of difficult removal of concrete pile heads, high risk of pile head hoisting, and long construction period, saving manpower and material resources. , easy to operate, the effect of reducing the degree of solidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

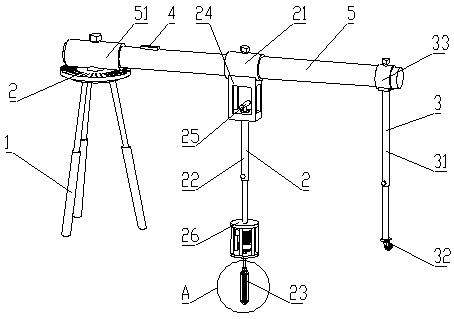

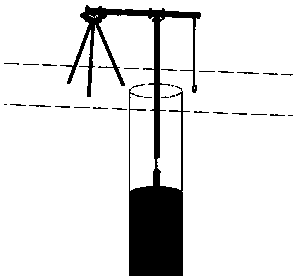

[0038] see figure 1 and figure 2 , the present invention provides a stirring and crushing device for bored cast-in-place pile heads, comprising a tripod 1, and a crossbar 5 horizontally arranged on the upper side of the tripod 1, the top of the tripod 1 is rotatably connected to one end of the crossbar 5, and the other end of the crossbar 5 One end is provided with a vertically downward support assembly 3; the middle part of the cross bar 5 is provided with a vertically downward stirring assembly 2;

[0039] The three supporting legs of the tripod 1 are all telescopic supporting legs;

[0040] The stirring assembly 2 includes a stirring assembly sleeve 21 sleeved in the middle of the cross bar 5 rod body, a vertical stirring main rod 22 is arranged on the lower side of the stirring assembly sleeve 21, and a stirring head 23 is provided at the lower end of the stirring main rod 22;

[0041] The support assembly 5 includes a support main rod 31 arranged below the end of the c...

Embodiment 2

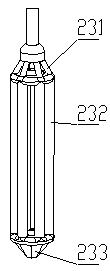

[0067] On the basis of Example 1, different from Example 1, the stirring head 23 includes three integrated upper, middle and lower parts, the upper part 231 and the lower part 233 are conical, and the middle part 232 is a columnar body;

[0068] Both the upper part 231 and the lower part 233 are composed of several inclined rods in a circumferential array, the tip of the upper part 231 is located at the upper end, the tip of the lower part 233 is downward, and several vertical rods are fixedly arranged between the inclined rods of the upper part 231 and the lower part 233, so that Said middle part 232 is made up of said several vertical bar body circle arrays;

[0069] The outer periphery of the junction of the upper part 231 and the middle part 232 and the outer periphery of the junction of the middle part 232 and the lower part 233 are respectively fixed with ring bodies.

[0070] The horizontal bar 5 of this scheme is made of commonly used shelf pipes, with a nominal diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com