Open caisson non-drainage sinking construction system and construction method thereof

A construction method and caisson technology, which are applied in caisson, infrastructure engineering, non-variable-capacity pumps, etc., can solve the problems of water and sand at the bottom of the well, inclination of the caisson, sudden sinking, etc., so as to avoid inclination or sudden sinking, Avoid caisson inclination or sudden sinking, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

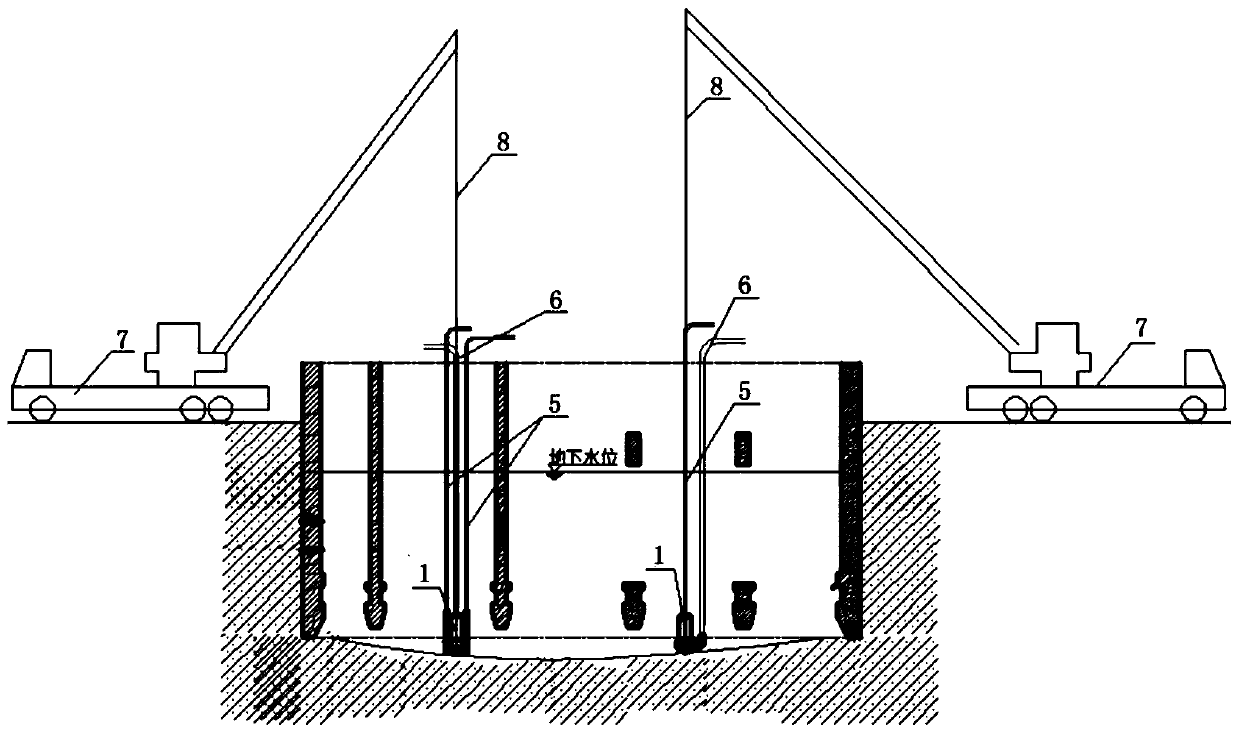

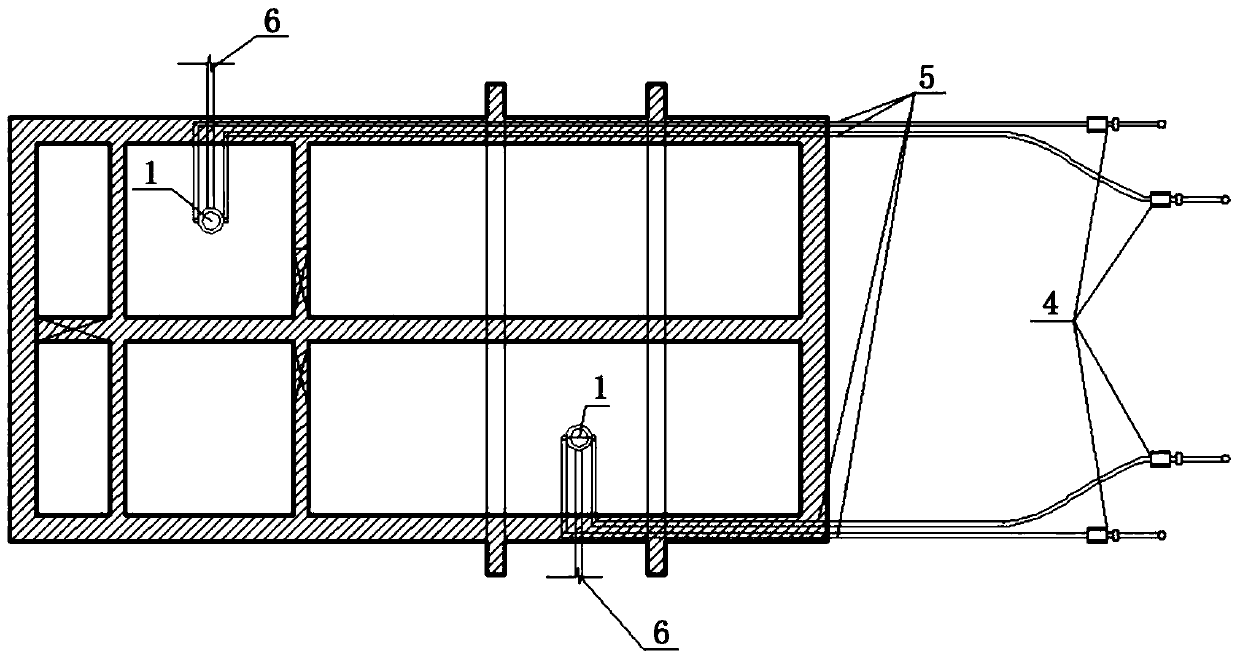

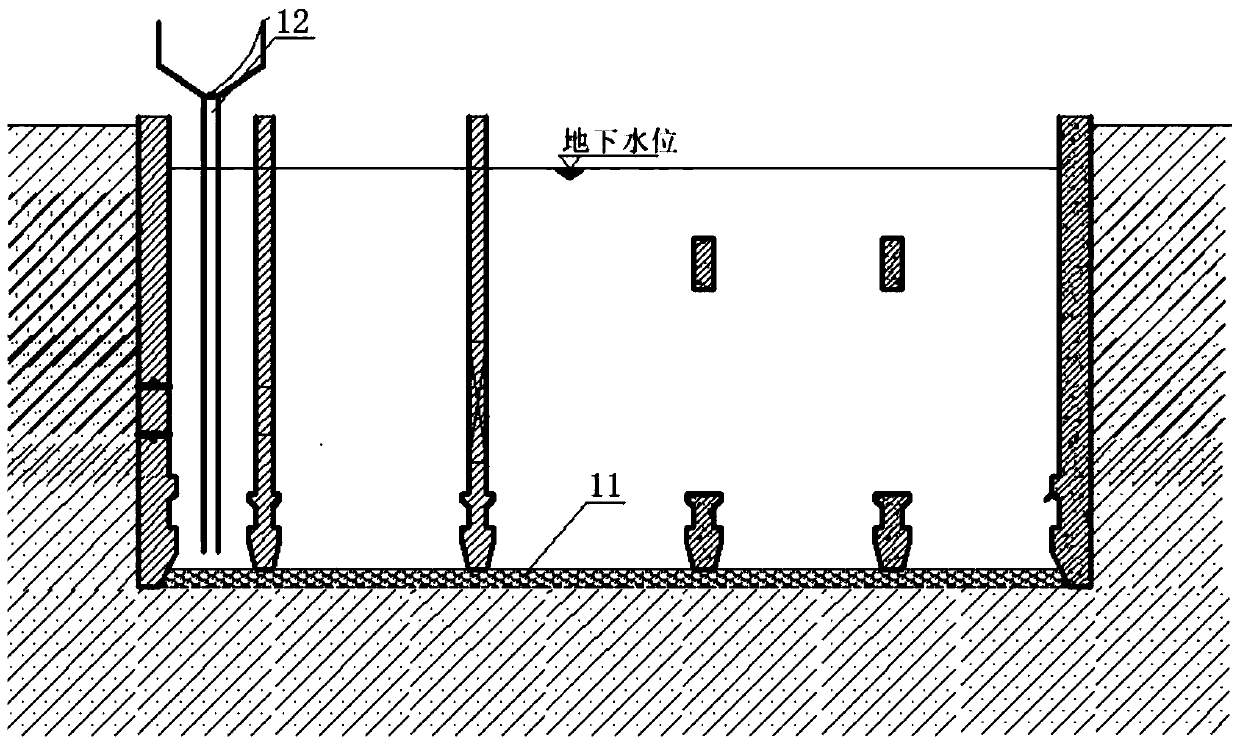

[0033] like Figure 1~5 As shown, the undrained caisson sinking construction system provided by the present invention has simple structure, scientific and reasonable design, and is easy to use, which can effectively avoid inclination or sudden sinking during the construction process of caisson sinking, and can effectively eliminate water gushing at the bottom of the well , The potential safety hazard of sand gushing, and can effectively improve the efficiency of caisson sinking construction. The undrained sinking construction system of the caisson of the present invention includes a truck crane 7 located on the ground at the side of the caisson, installed on the traction rope 8 of the truck crane 7 for diving to the bottom of the caisson through the truck crane 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com