Firmly-mounted ceiling

A ceiling and ceiling technology, applied in building components, buildings, ceilings, etc., can solve the problems of single assembly method, inconvenient combined installation, and insufficient installation, and achieve the effect of firm installation, convenient assembly and disassembly, and simple assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

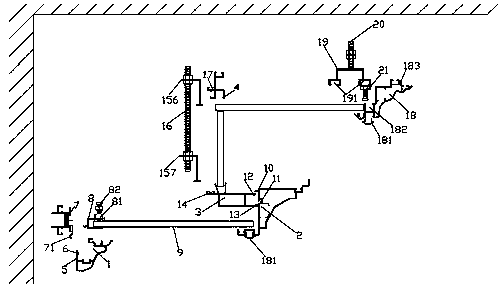

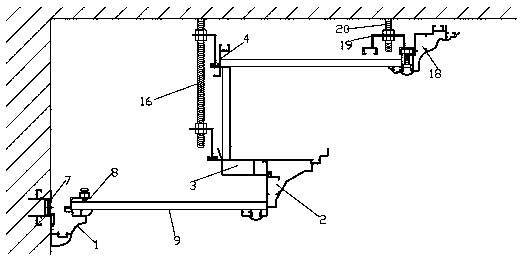

[0031]An upper tab 12 and a lower tab 13 are installed on the secondary beam 3 of the ceiling, and the upper tab 12 and the lower tab 13 are used as a connection transition part, so that the ceiling connecting plate 2 passes through the upper slot 10 and the lower slot 11 The upper tab 12 and the lower tab 13 are connected to each other on the secondary beam 3 of the ceiling, and the secondary beam 3 of the ceiling and the transition bar 4 of the ceiling are respectively provided with wallboard placement grooves, and the wallboards 9 are respectively fixed and installed. In the wall panel placement groove on the ceiling secondary beam 3 and the ceiling transition bar 4, a lower hanging buckle groove 14 is also installed on one side of the wall panel placement slot on the ceiling secondary beam 3, and at the same time on the ceiling transition bar 4 An upper hanging buckle groove 17 is also installed on one side of the wallboard placing groove, the upper hanging buckle groove 17...

Embodiment 2

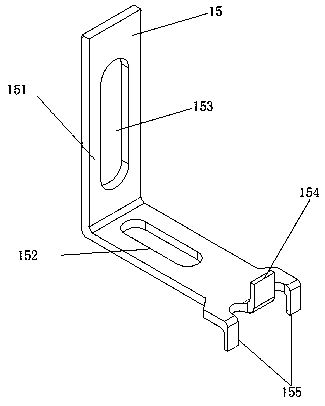

[0034] The ceiling main keel 19 is fixed on the ceiling frame gusset 18 through bolts 22, and the lower end of the ceiling main keel 19 is equipped with a bolt installation groove 22, and the bolt 21 is used as a transitional connection part so that the ceiling transition strip 44 is connected to the ceiling main keel 19 At the same time, the second threaded rod 20 is installed on the main keel 19 of the ceiling, and the first threaded rod 16 is respectively connected and fixed by the hanging buckle 15 to the secondary ceiling beam 3 and the ceiling transition bar 4, and between the ceiling secondary beam 3 and the ceiling transition bar 4 Wall panels 9 are installed respectively, and the first threaded rod 16 and the second threaded rod 20 are directly installed and fixed on the ceiling, and both are fixed at the same time, so that the installation of the whole ceiling is firmer, and the bearing pressure of the main keel 19 of the ceiling is also alleviated. At the same time, ...

Embodiment 3

[0037] A firmly installed ceiling provided by the present invention is abutted and fixed on the wall by the edge surface 5 on the ceiling edge strip 1. A hook 6 is provided on the upper end of the edge surface 5, and an engaging portion is provided on the fixed track 7. 71, the fixed rail 7 is engaged with the hook 6 through the occlusal part 71, and the fixed rail 7 is installed inside the wall. A building block 8 is installed in the groove at the upper end of the ceiling edge strip 1, and a screw mounting groove 81 is provided on the building block 8, and a screw 82 is installed on the screw mounting groove 81, and the screw 82 directly abuts on the wallboard 9, which also plays a role The role of fixed wall panels. There is a chute on the ceiling connection plate 2, and the wall panel 9 is stably installed between the ceiling edge strip 1 and the ceiling connection plate 2 through the building block 6 and the chute. 1 is abutted and fixed on the wall, and at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com