Green roof system applied to sponge city construction

A sponge city and green technology, applied in roofing, application, construction, etc., can solve the problems of complex construction and heavy loads of green roofs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

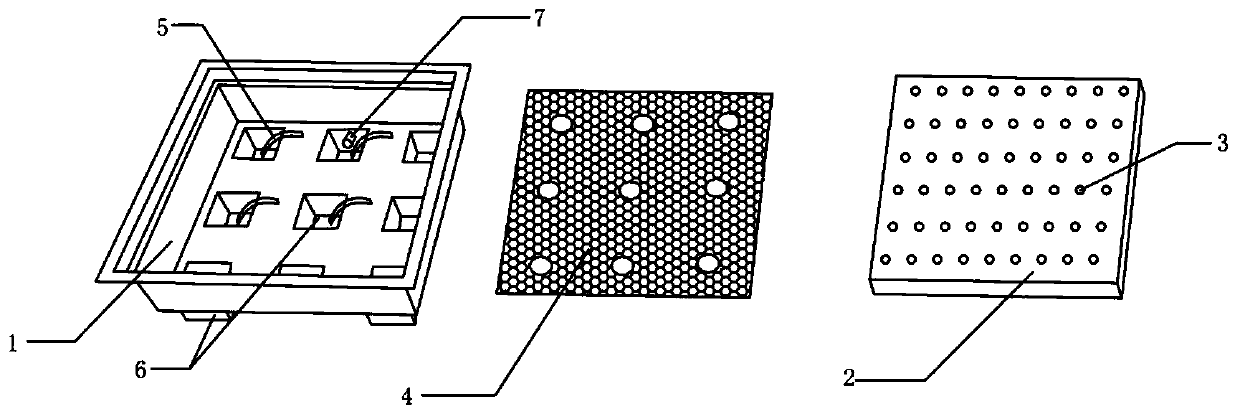

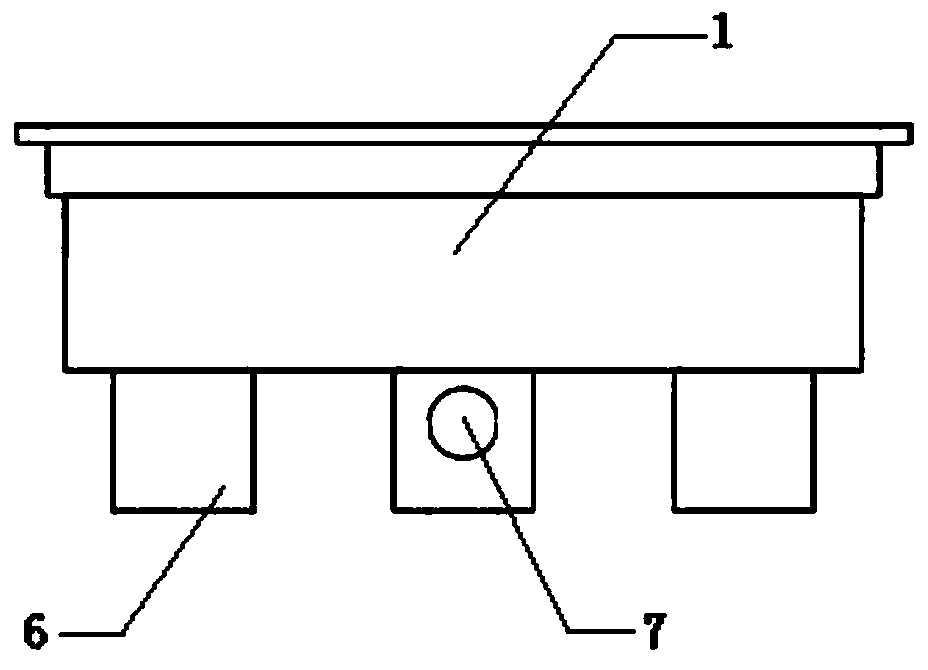

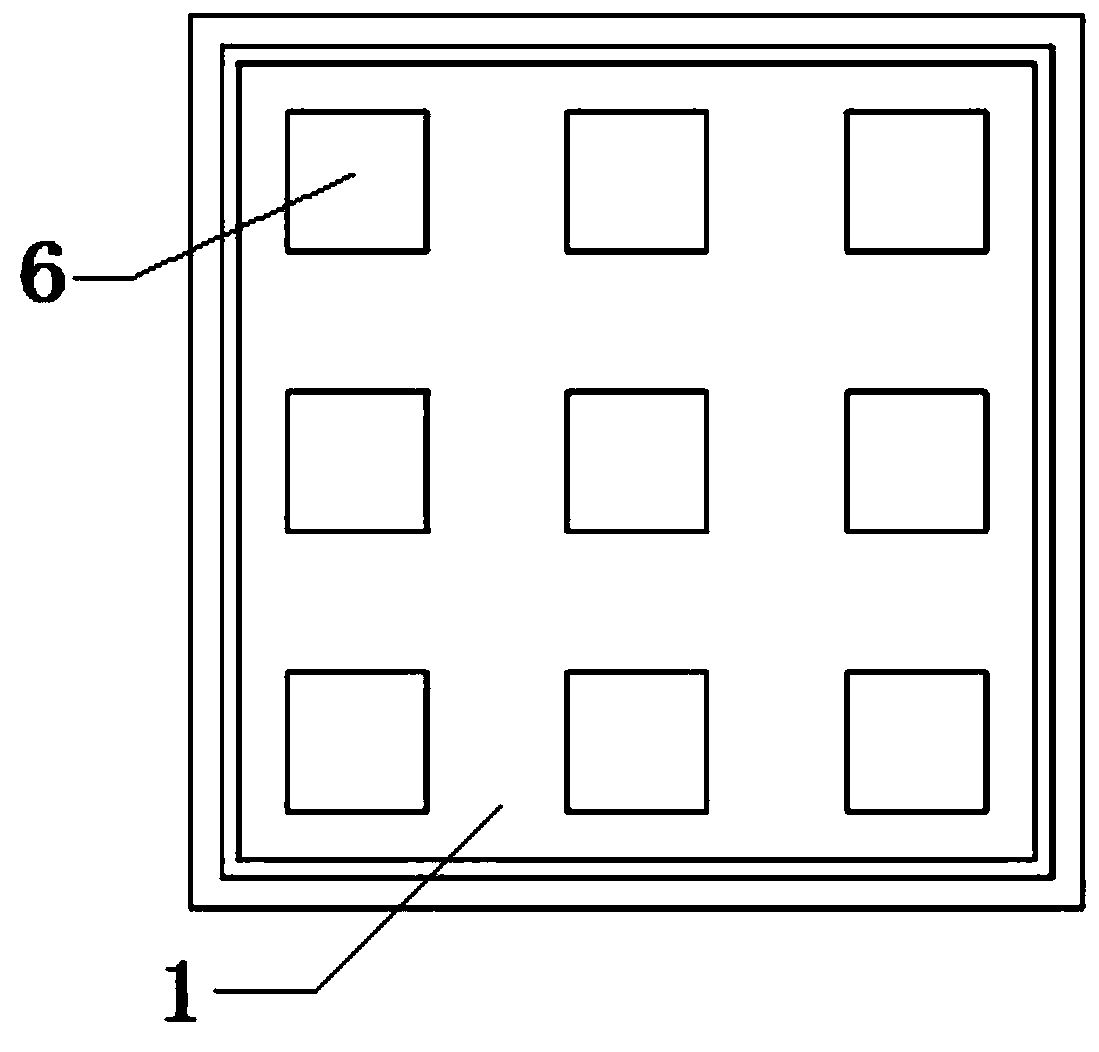

[0026] like Figure 1 to Figure 4 As shown, the present embodiment provides a green roof system for sponge city construction. The green roof system has the characteristics of cutting type, light weight, and rain-fed type. It includes a plurality of modular containers 1 and a porous sponge cultivation substrate 2. , a filter screen 4 and a plurality of absorbent cotton strips 5, and a plurality of modular containers 1 are placed on the roof. It should be noted that the modular container 1 has a relatively small structure, which splits the large area of the roof into multiple small areas for planting green plants. When greening the roof, it is only necessary to arrange multiple modular containers 1 side by side or Just place it on the roof, and then plant plants in the module container 1, and the operation is very convenient.

[0027] Specifically, the interior of the modular container 1 is hollow to form a planting space, and an opening is provided on the top of the modular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com