Sheet metal part bending and edge lap joint structure

A technology of sheet metal parts and long folding, applied in the field of sheet metal, can solve problems such as difficult positioning, achieve the effect of convenient welding, overcome elasticity, and facilitate welding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

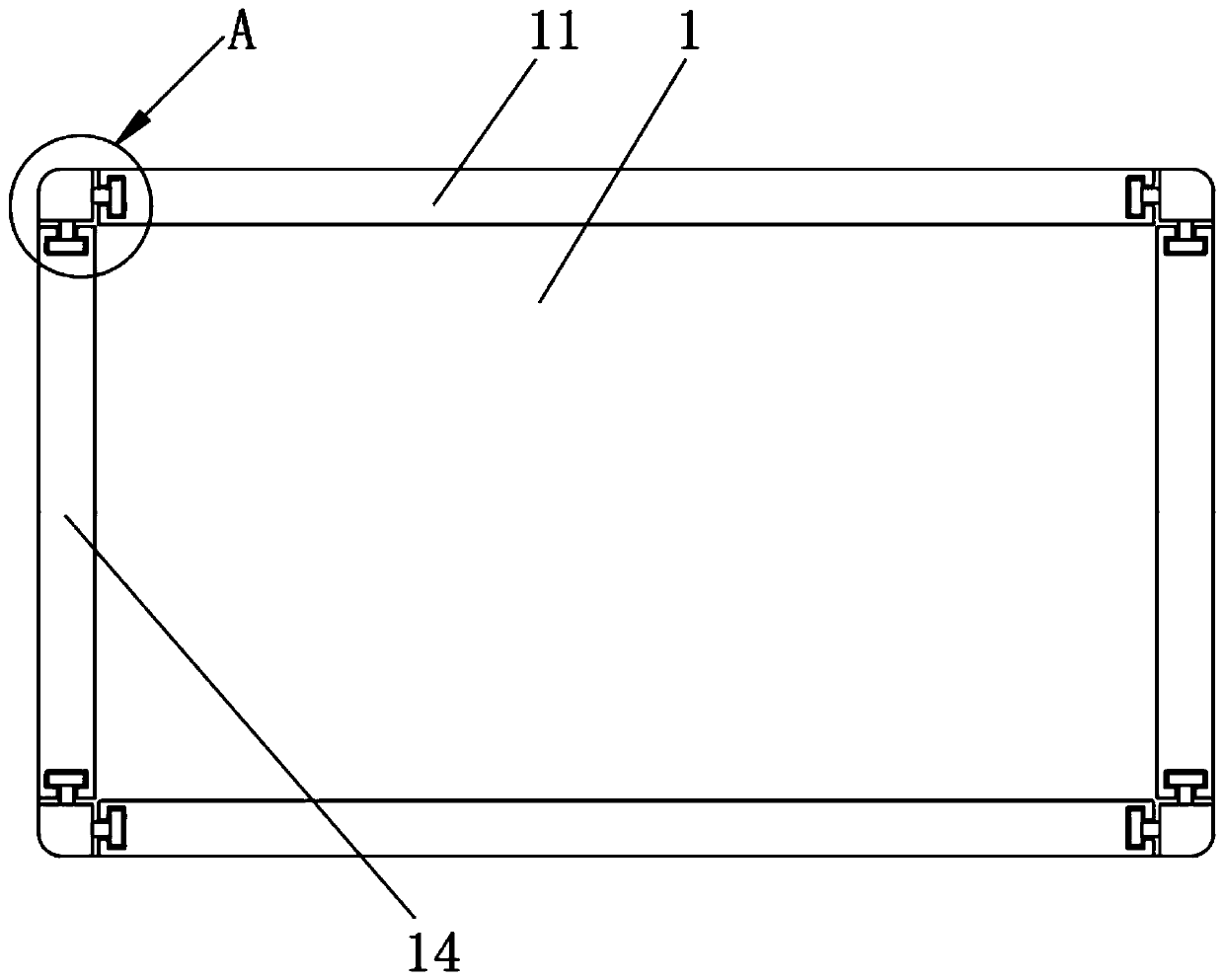

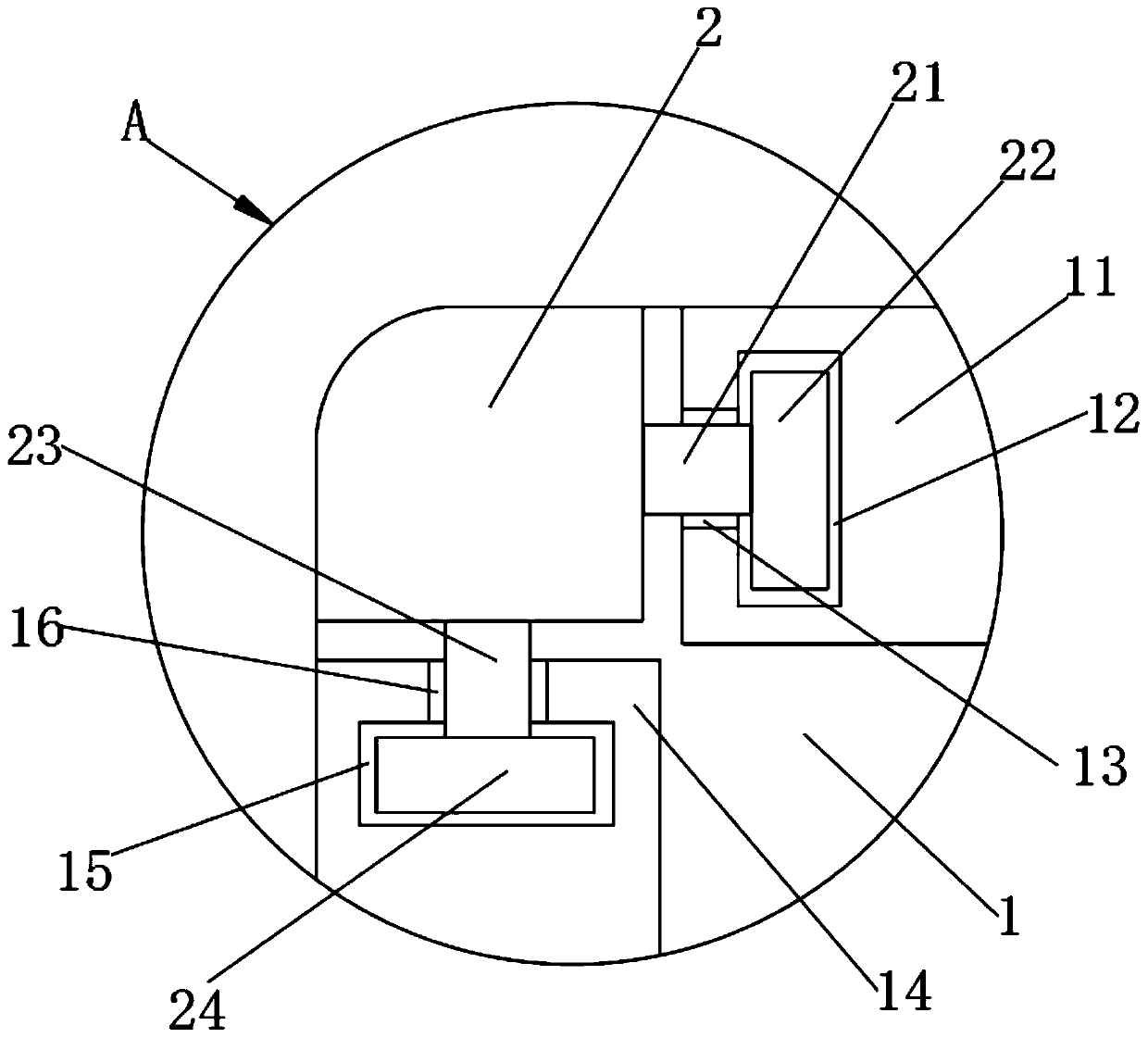

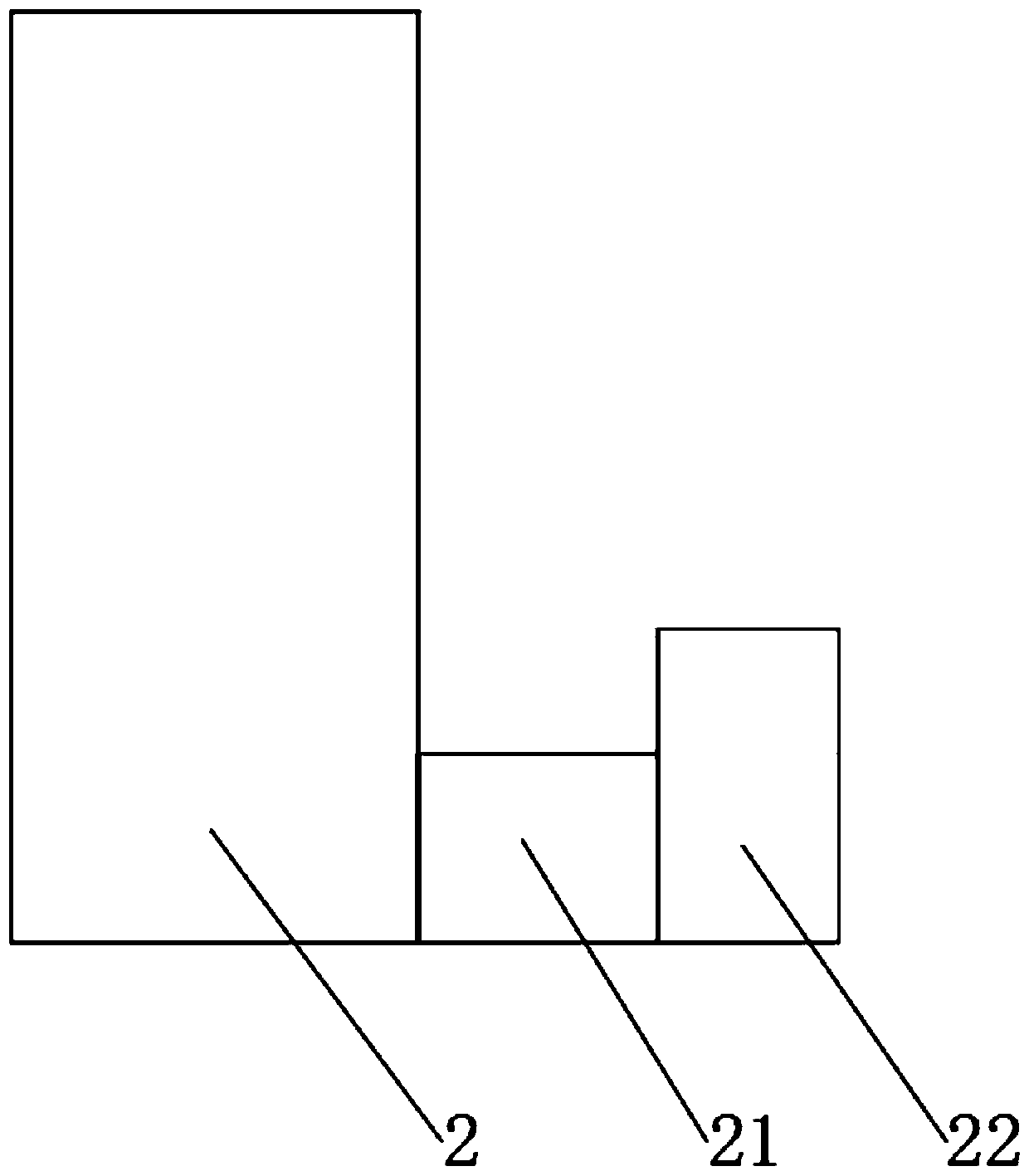

[0022] see figure 1 , figure 2 , a sheet metal bending lap structure, including a cover plate 1, the upper and lower ends of the cover plate 1 are provided with long folds 11, and the long folds 11 are provided with a first clamping groove 12 and a first connecting groove 13, The left and right sides of the cover plate 1 are provided with short folds 14, the short folds 14 are provided with a second card slot 15 and a second connecting groove 16, and the edges of the long folds 11 and the short folds 14 are provided with lap strips 2. The surface of the lapping strip 2 is provided with a first connecting block 21, the end of the first connecting block 21 is provided with a first clamping block 22, the lower end of the lapping strip 2 is provided with a second connecting block 23, and the second connecting block 23 The lower end of the second block 24 is provided.

[0023] see figure 2 , the first clamping slot 12 communicates with the first connecting slot 13 , the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com