Pipeline valve box and groove type wet processing equipment

A pipeline valve and pipeline technology, applied in mechanical equipment, pipeline systems, gas/liquid distribution and storage, etc., can solve the problems of operator injury, scattered valve settings, inconvenient operation, etc., achieve maintenance and repair safety, and prevent continuous , Reduce the effect of leakage hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

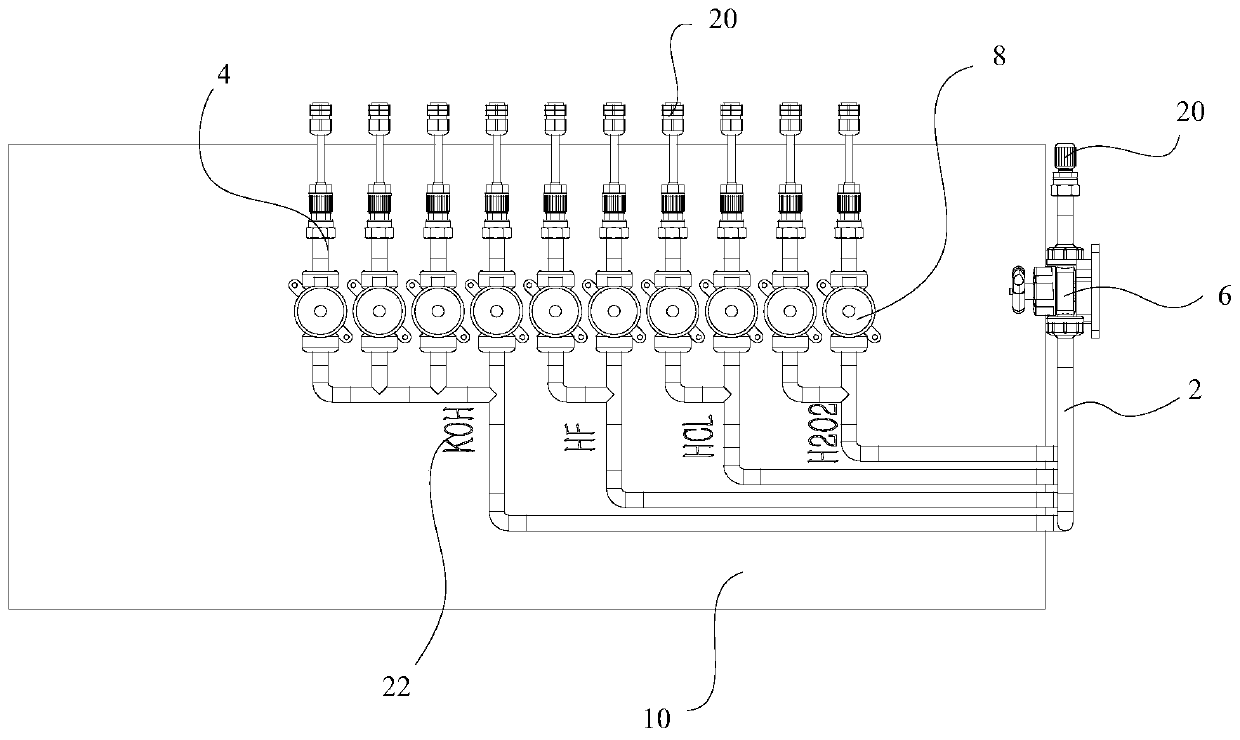

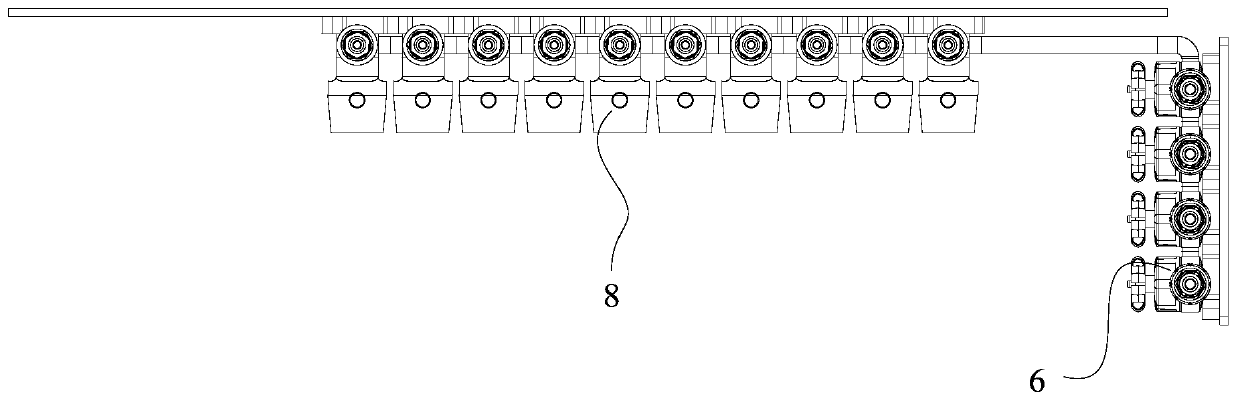

[0046] Such as Figure 1 to Figure 4 As shown, the first embodiment of the present invention provides a pipeline valve box including: a pipeline, a manual valve 6 , a pneumatic valve 8 and a box body 10 .

[0047] Wherein, the pipeline includes at least one supply pipeline 2, and each supply pipeline 2 communicates with at least one branch pipeline 4; the manual valve 6 is arranged on the supply pipeline 2; the pneumatic valve 8 is arranged on the branch pipeline 4; On the pipeline 2 and the branch pipeline 4 , the manual valve 6 and the pneumatic valve 8 are located in the box body 10 .

[0048] The present invention arranges the supply pipeline 2 and the branch pipeline 4 in the box body 10 through the arrangement of the pipeline, the manual valve 6, the pneumatic valve 8 and the box body 10, the manual valve 6 is arranged on the supply pipeline 2, and the pneumatic valve 8 is arranged on the branch pipeline. On the pipeline 4, the manual valve 6 and the pneumatic valve 8 t...

Embodiment 2

[0051] Such as Figure 1 to Figure 4 As shown, the first embodiment of the present invention provides a pipeline valve box including: a pipeline, a manual valve 6 , a pneumatic valve 8 and a box body 10 .

[0052] Wherein, the pipeline includes at least one supply pipeline 2, and each supply pipeline 2 communicates with at least one branch pipeline 4; the manual valve 6 is arranged on the supply pipeline 2; the pneumatic valve 8 is arranged on the branch pipeline 4; On the pipeline 2 and the branch pipeline 4 , the manual valve 6 and the pneumatic valve 8 are located in the box body 10 .

[0053] Further, the pipeline valve box further includes: a liquid leakage detection switch, which is arranged on at least one of the branch pipeline 4 , the supply pipeline 2 and the box body 10 .

[0054] In this embodiment, due to the sporadic nature of liquid leakage in the production process, there are usually no full-time personnel to observe whether there is liquid leakage in the pipe...

Embodiment 3

[0058] Such as Figure 1 to Figure 7 As shown, the first embodiment of the present invention provides a pipeline valve box including: a pipeline, a manual valve 6 , a pneumatic valve 8 and a box body 10 .

[0059] Wherein, the pipeline includes at least one supply pipeline 2, and each supply pipeline 2 communicates with at least one branch pipeline 4; the manual valve 6 is arranged on the supply pipeline 2; the pneumatic valve 8 is arranged on the branch pipeline 4; On the pipeline 2 and the branch pipeline 4 , the manual valve 6 and the pneumatic valve 8 are located in the box body 10 .

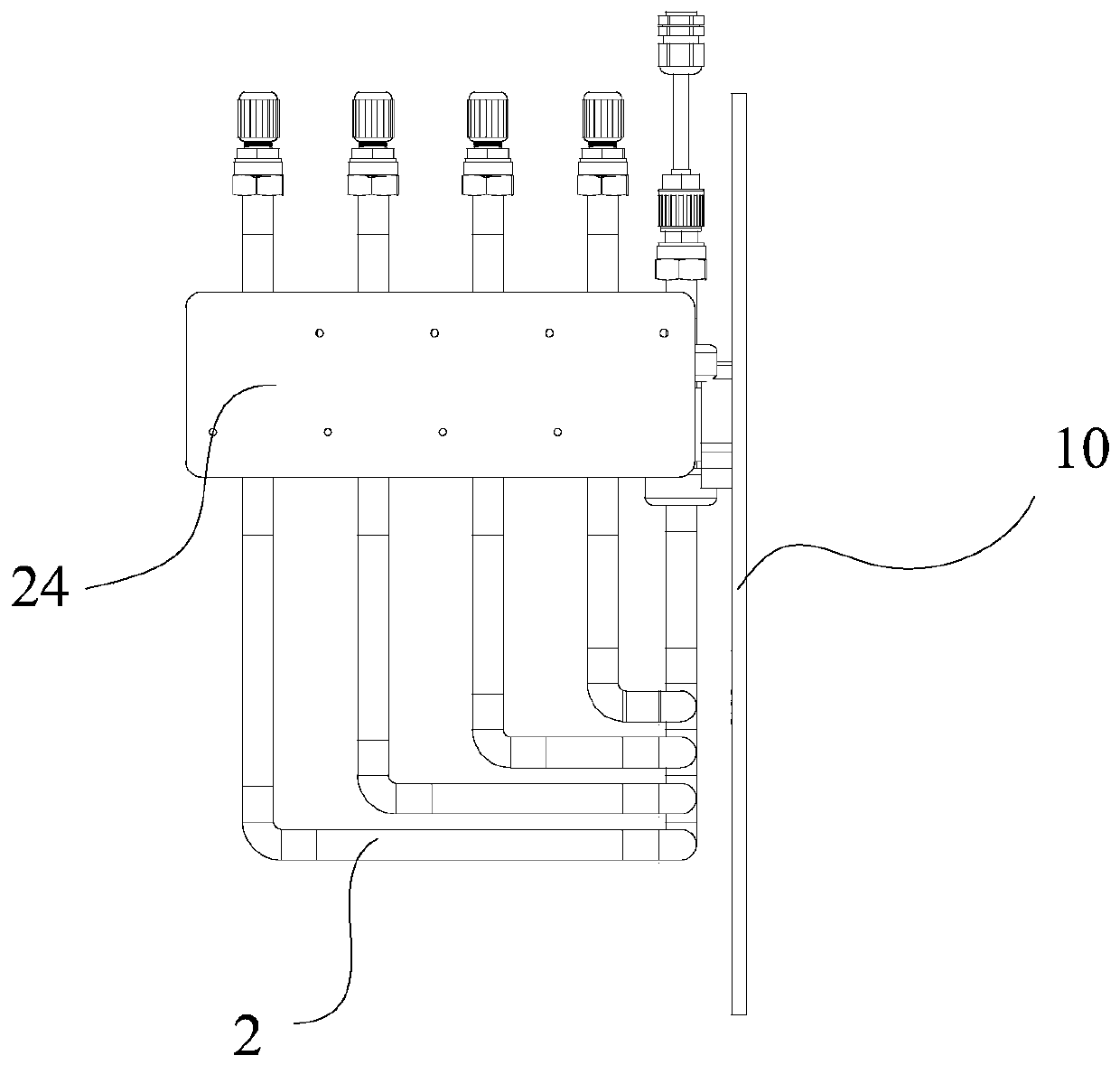

[0060] Further, as Figure 5 Shown, box body 10 comprises: box body body 12; Top plate 14, is hinged on box body body 12 tops, and branch pipeline 4 stretches out box body body 12 through the gap between box body body 12 and top plate 14; Bottom plate 16, connects In the box body 12, it is located at the bottom of the box body 12; the pipeline fixing plate 24, the supply pipeline 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com