Casting molten metal smelting system and a mounting method thereof

A technology of casting metal and installation method, which is applied in the direction of crucible furnace, furnace, lighting and heating equipment, etc., can solve the problems of damaged furnace lining, inconvenient replacement of crucible, leakage of furnace, etc., so as to ensure the reliability of use, enhance high temperature resistance, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

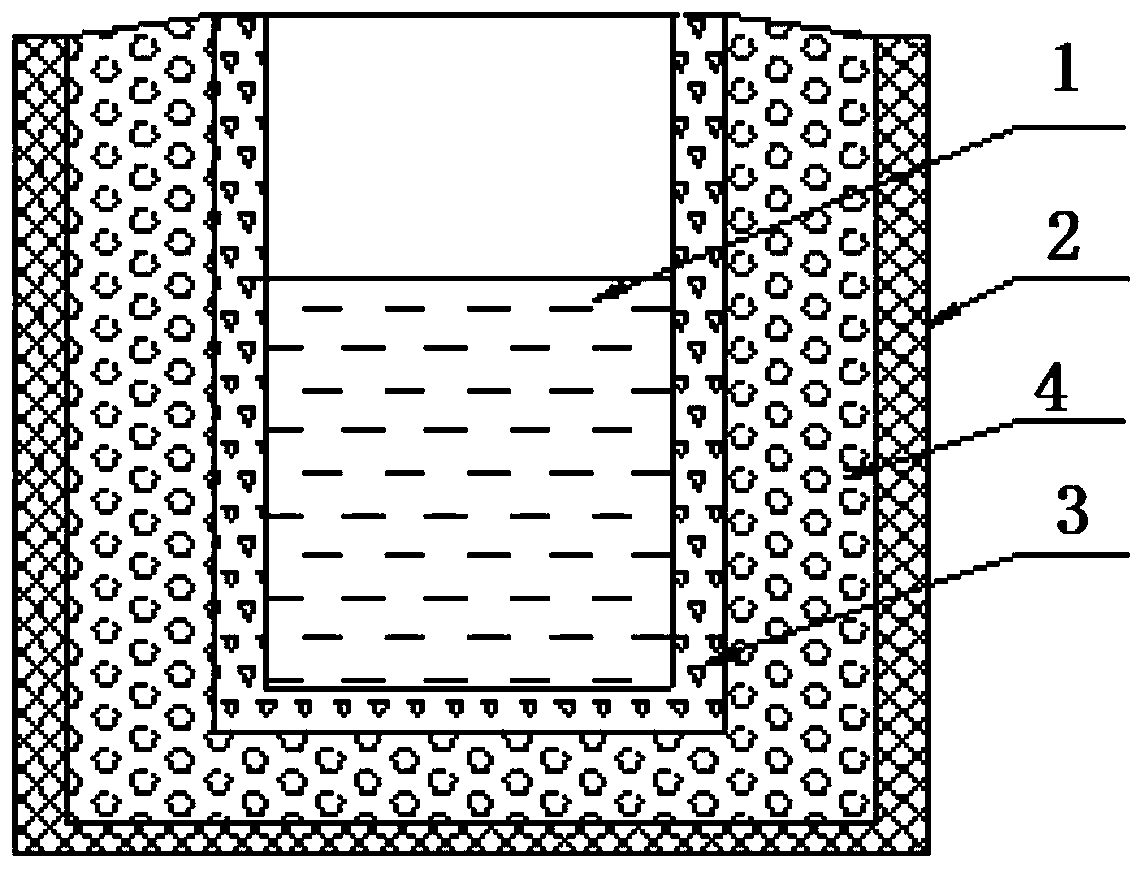

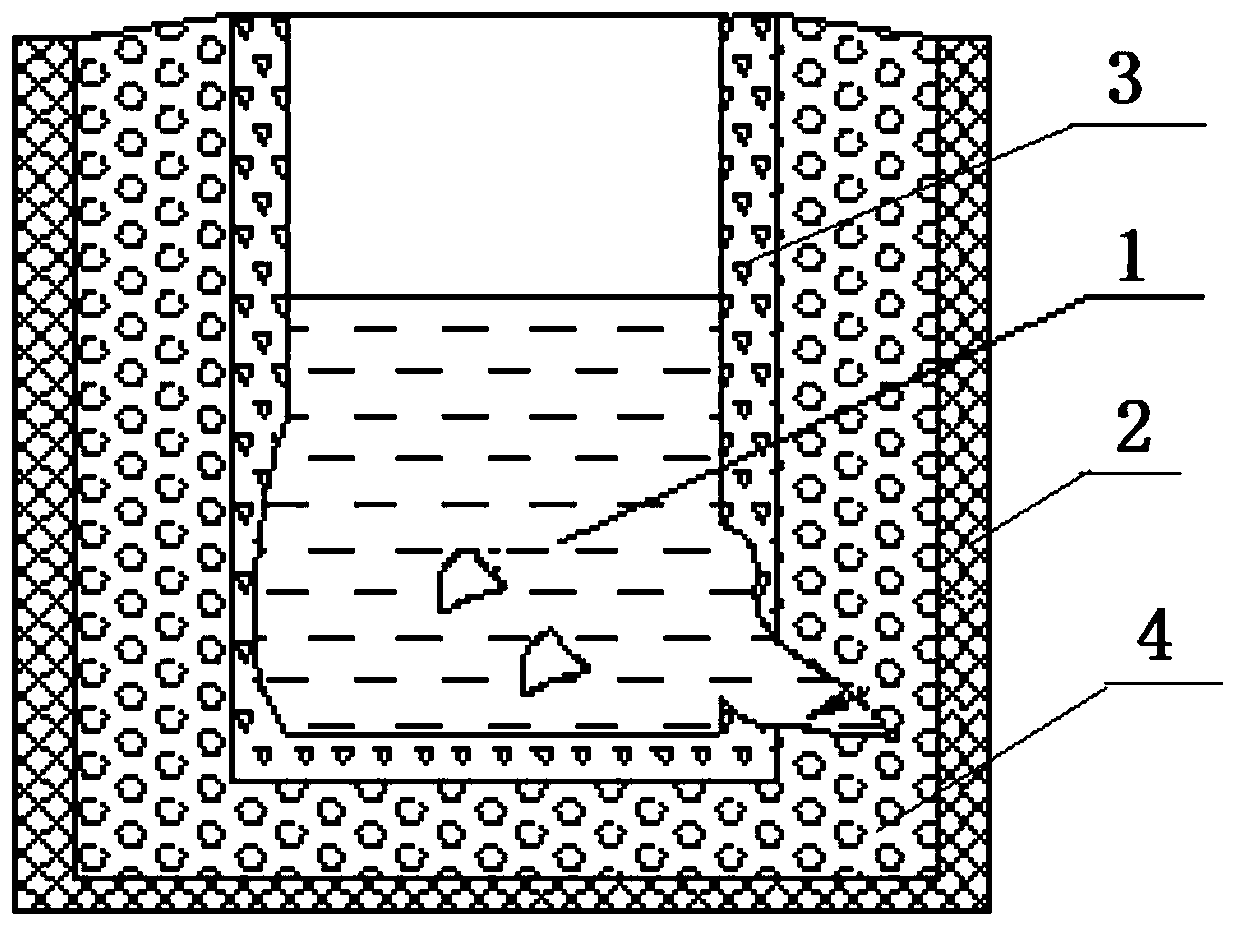

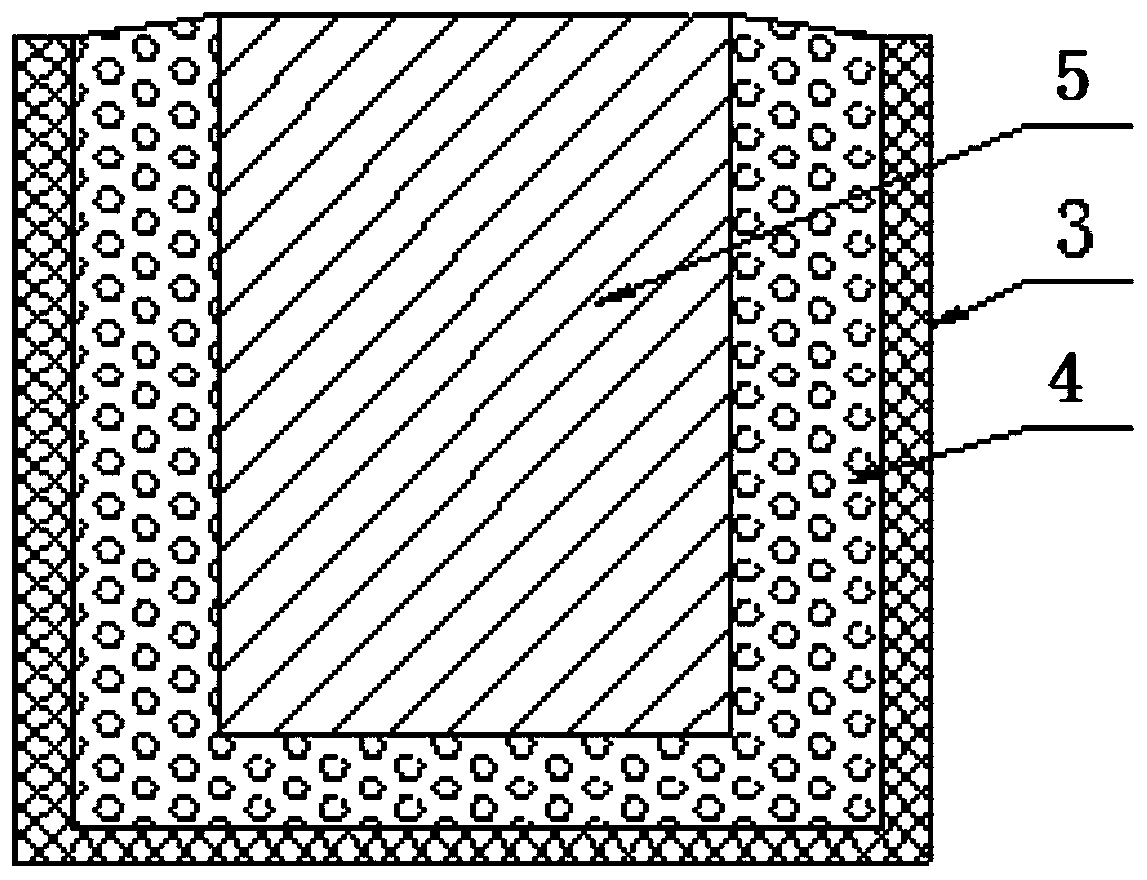

[0026] Such as image 3 , Figure 4 and Figure 5 As shown, the present invention provides a method for installing a casting molten metal smelting system, comprising the following steps:

[0027] Step 1: Provide a heating device 2 with one end open, a crucible 3 with an open end and a granular furnace lining material, and then prepare a crucible mold 5 according to the shape of the crucible 3, so that the shape of the crucible mold 5 is consistent with the crucible 3, and the outline of the crucible mold 5 The difference between the dimension and the outline dimension of the crucible 3 is Δδ, and Δδ is a non-zero positive real number; further, the difference Δδ between the outline dimension of the crucible mold 5 and the outline dimension of the crucible 3 in step 1 is 6mm to 8mm. The pot mold in the preferred step 1 is made of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com