Servo driver and servo drive system

A servo drive and servo drive technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve problems such as poor reliability of data communication and unsatisfactory data frame transmission speed, so as to solve communication obstacles and improve data transmission rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

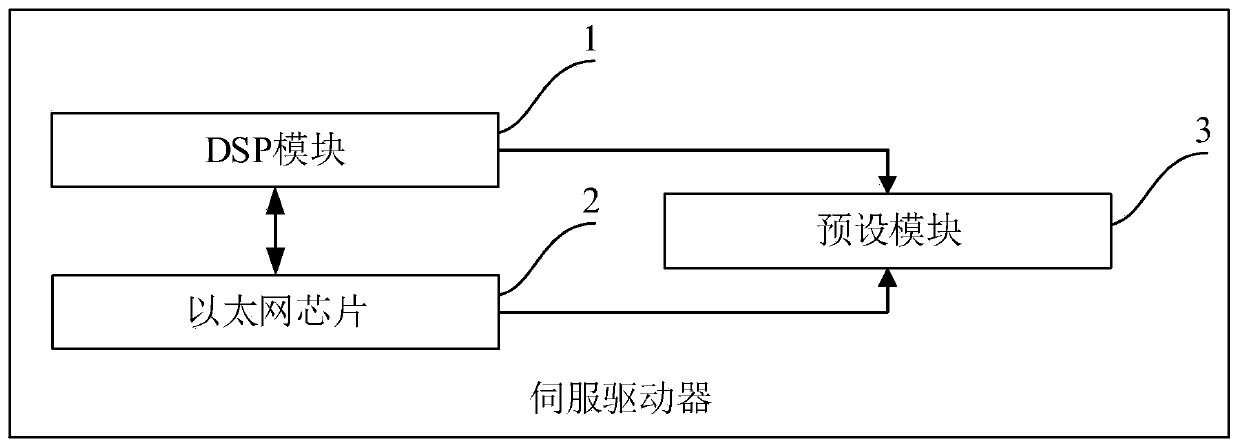

[0046] Such as figure 1 As shown, the servo driver of this embodiment includes a DSP module 1 , an Ethernet chip 2 and a preset module 3 .

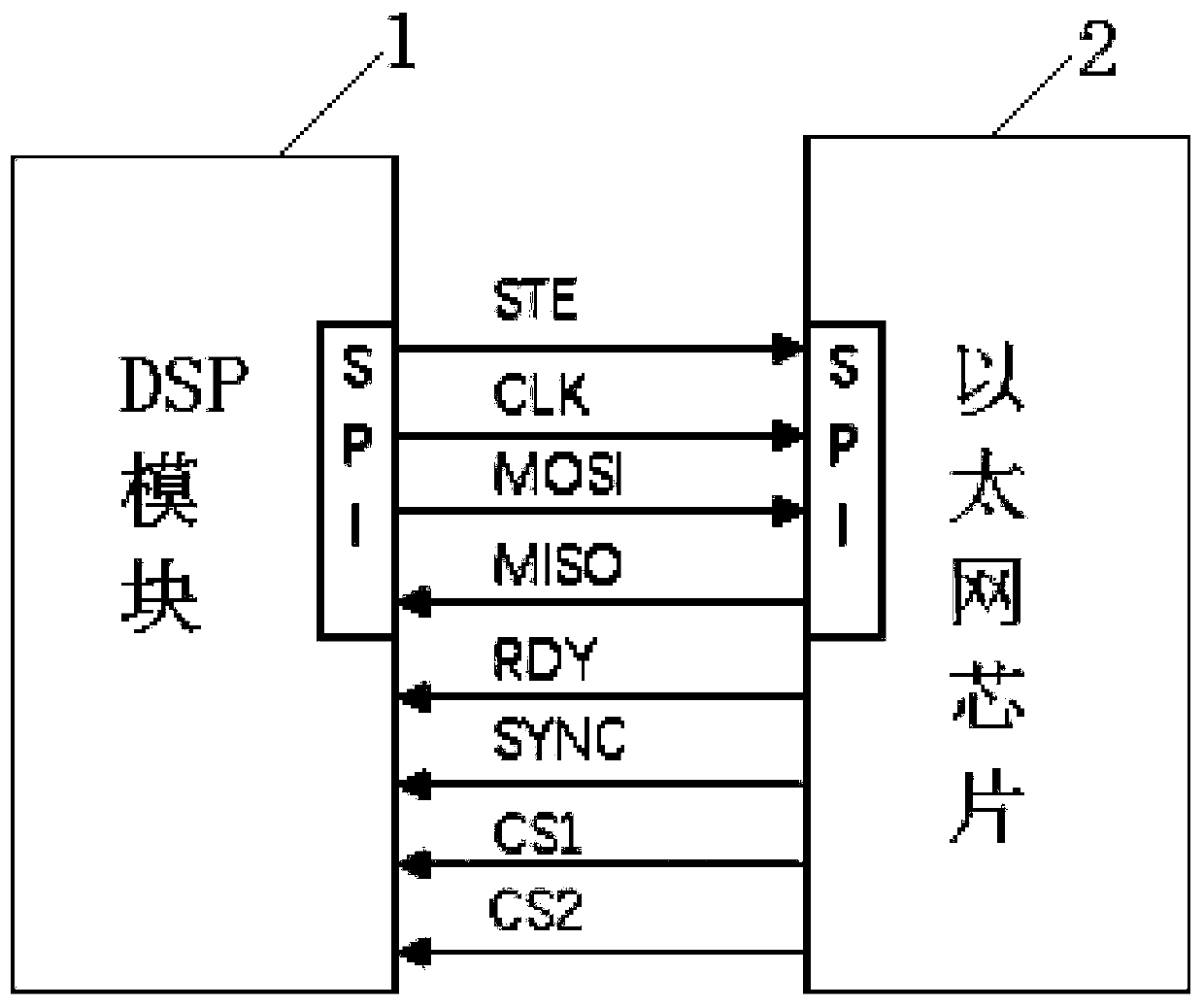

[0047] The communication connection between the DSP module 1 and the Ethernet chip 2 is carried out through the SPI interface;

[0048] Wherein, the DSP module 1 corresponds to the first communication protocol, and the Ethernet chip 2 corresponds to the second communication protocol;

[0049] Specifically, the DSP module 1 may use a TMS320F2809 chip, or other chips such as DSP28 series. Wherein, the communication protocol adopted by the DSP module 1 is the Modbus protocol.

[0050] Ethernet chip 2 is a chip supporting EtherCAT communication function, such as XMC4300 chip, or combination of STM32 chip and ET1100 chip, combination of STM32 chip and ET1200 chip, combination of DSP and ET1100 chip, combination of DSP and ET1200 chip, etc. Among them, the XMC4300 chip integrates the functions of the STM32 chip (or DSP) and ET1X00, and the X...

Embodiment 2

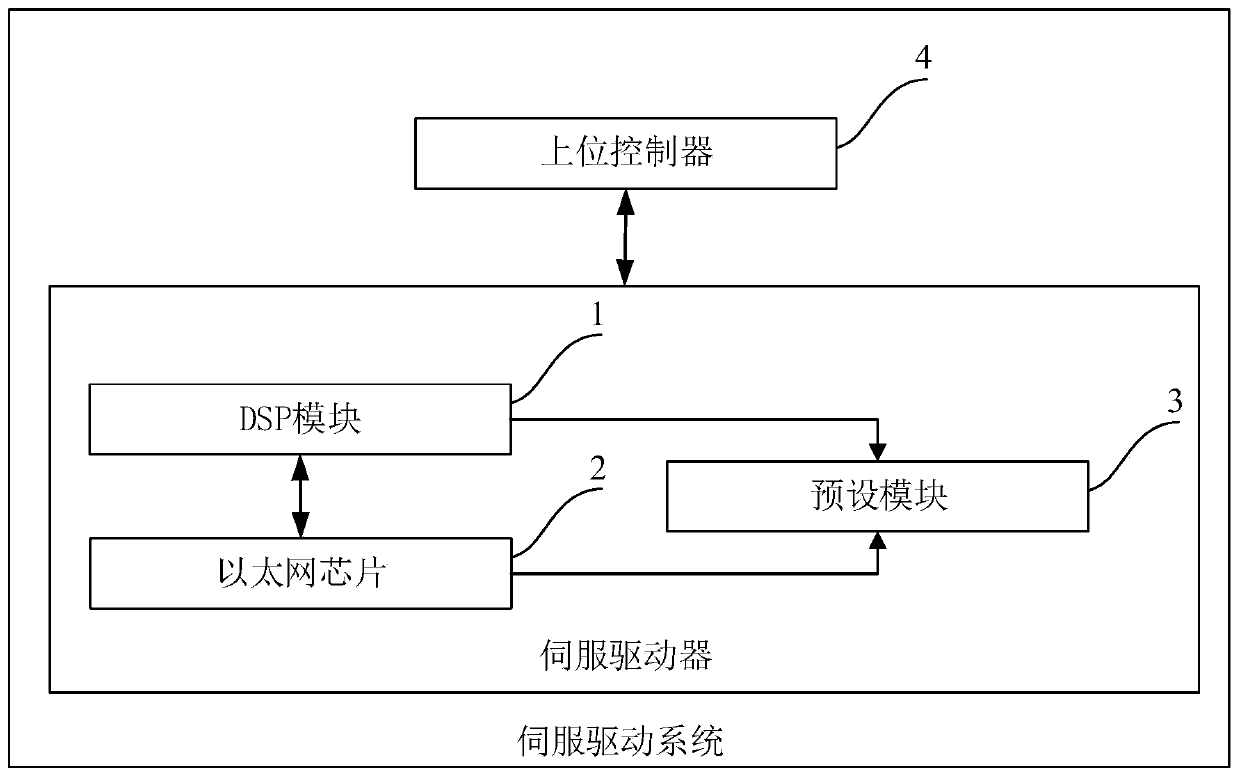

[0072] Such as image 3 As shown, the servo drive system in this embodiment includes the servo drive in Embodiment 1, and the servo drive system also includes a host controller 4 .

[0073] The host controller 4 communicates with the Ethernet chip 2;

[0074] During EtherCAT communication transmission, the Ethernet chip 2 acts as the master station, and the DSP module 1 acts as the slave station. The master station is used to send request data to the slave station, and the slave station is used to send the required data to the slave station.

[0075] The data transmission between DSP module 1 and Ethernet chip 2 follows the requirement that a command (request or response) corresponds to a data value, wherein the length of the command and data is 1 word, and the upper two bits in the command word are the command The type (request or response), the lower 14 bits of the command word is the address value, see the following table for details:

[0076]

[0077] During EtherCAT ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com