Gas injection device applied to lotus-root-shaped structure low-capacitance coaxial line

A low-capacitance, coaxial line technology, applied in the direction of electrical components, coaxial cables, circuits, etc., can solve the problems of unstable air hole uniformity inside the insulation, unstable capacitance value and impedance value of the finished insulated wire, etc., to increase Capacitance stability, effect of small insulation outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be explained more clearly and completely through the description of preferred embodiments of the present invention in conjunction with the accompanying drawings.

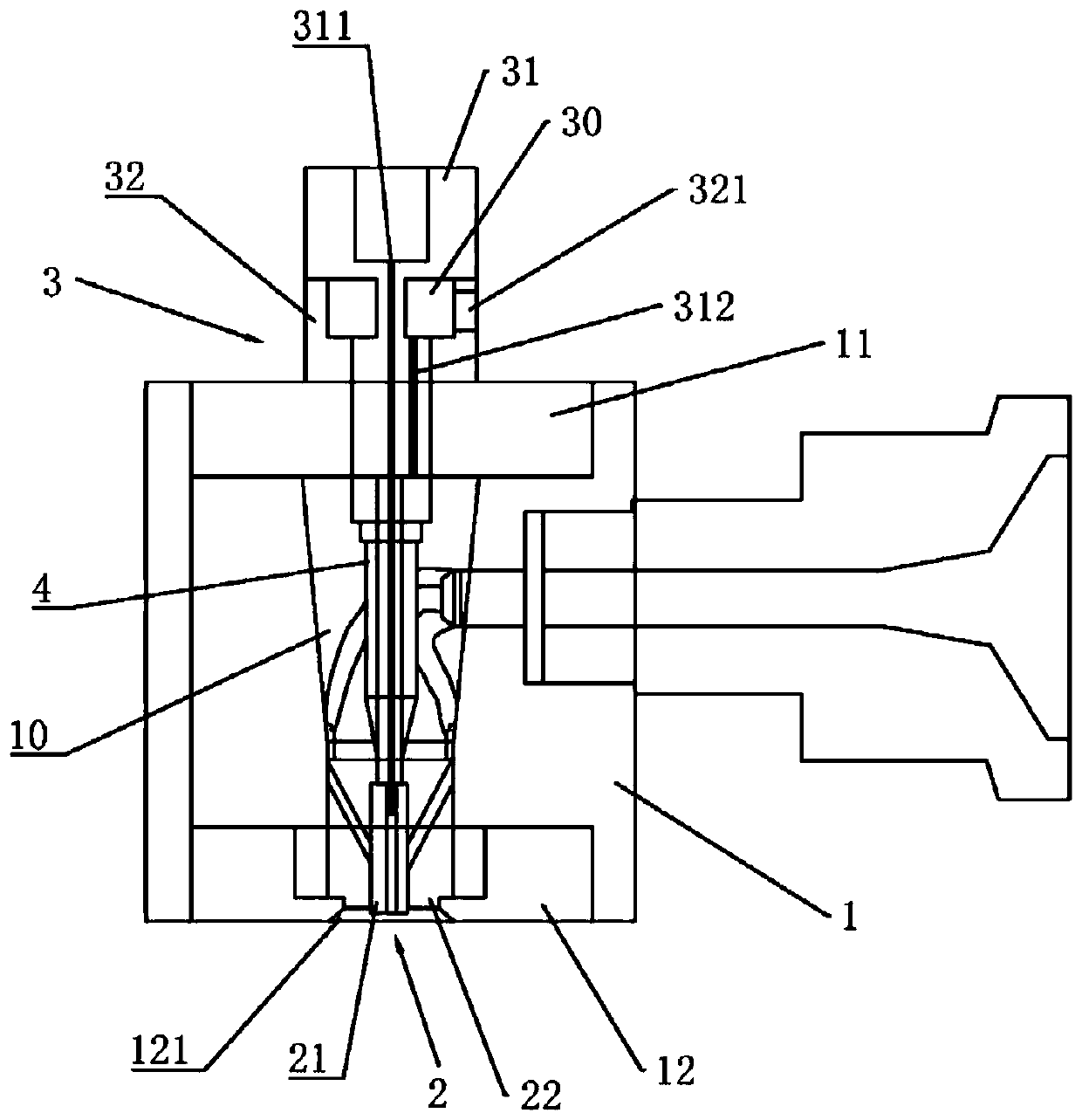

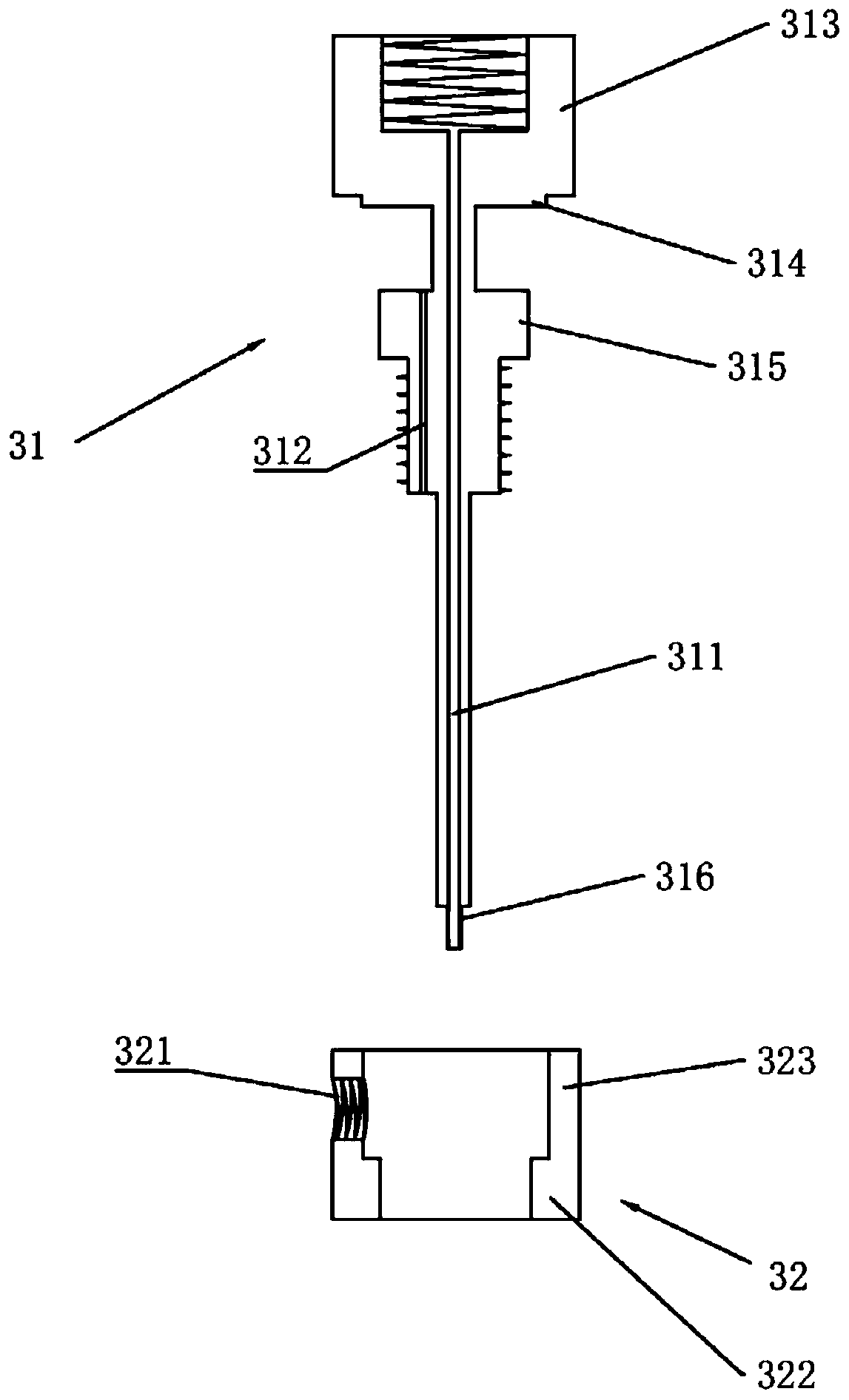

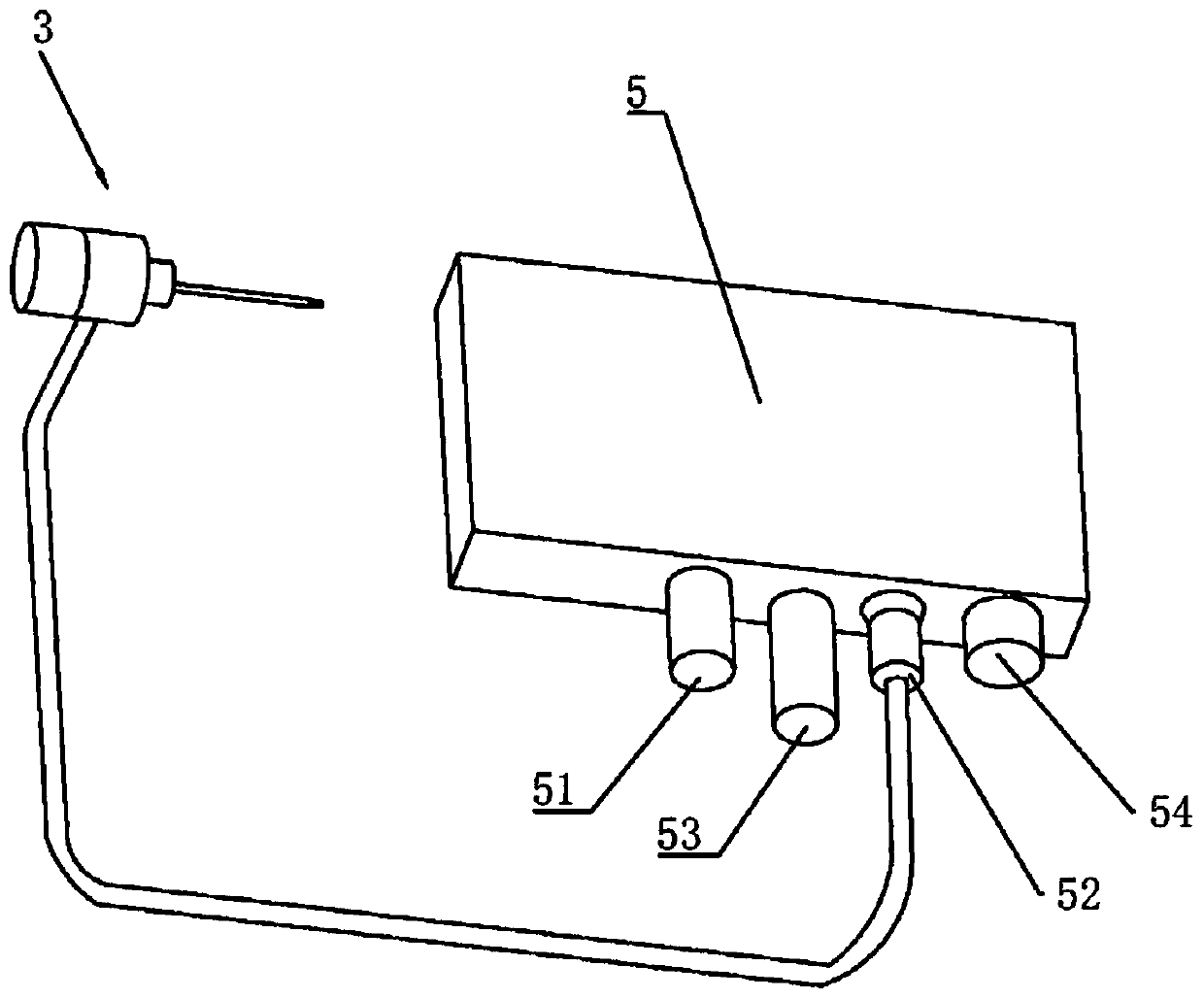

[0023] Such as figure 1 As shown, the preferred embodiment of the present invention is a gas injection device applied to a low-capacitance coaxial line with a lotus structure, including an extruder head 1 arranged on a fluoroplastic extruder, and the upper and lower ends of the extruder head 1 are open and placed A through accommodation chamber 10 is formed between the openings at both ends. The accommodation chamber 10 is vertically arranged. The molten plastic extruded from the head of the fluoroplastic extruder flows downward in the vertical direction in the extrusion head 1, so that the molten fluorine When the plastic is extruded, it is in a state of natural drooping, which can avoid deformation and internal collapse caused by gravity. The top of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap