MEMS microphone

A microphone and filter technology, which is applied in the direction of microphone structure association, microphone mouth/microphone accessories, microelectronic microstructure devices, etc., can solve problems such as MEMS microphone interference, large resistance, and MEMS microphone signal-to-noise ratio reduction, and achieve Effects of maintaining acoustic performance, preventing airflow impact, and reducing package size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

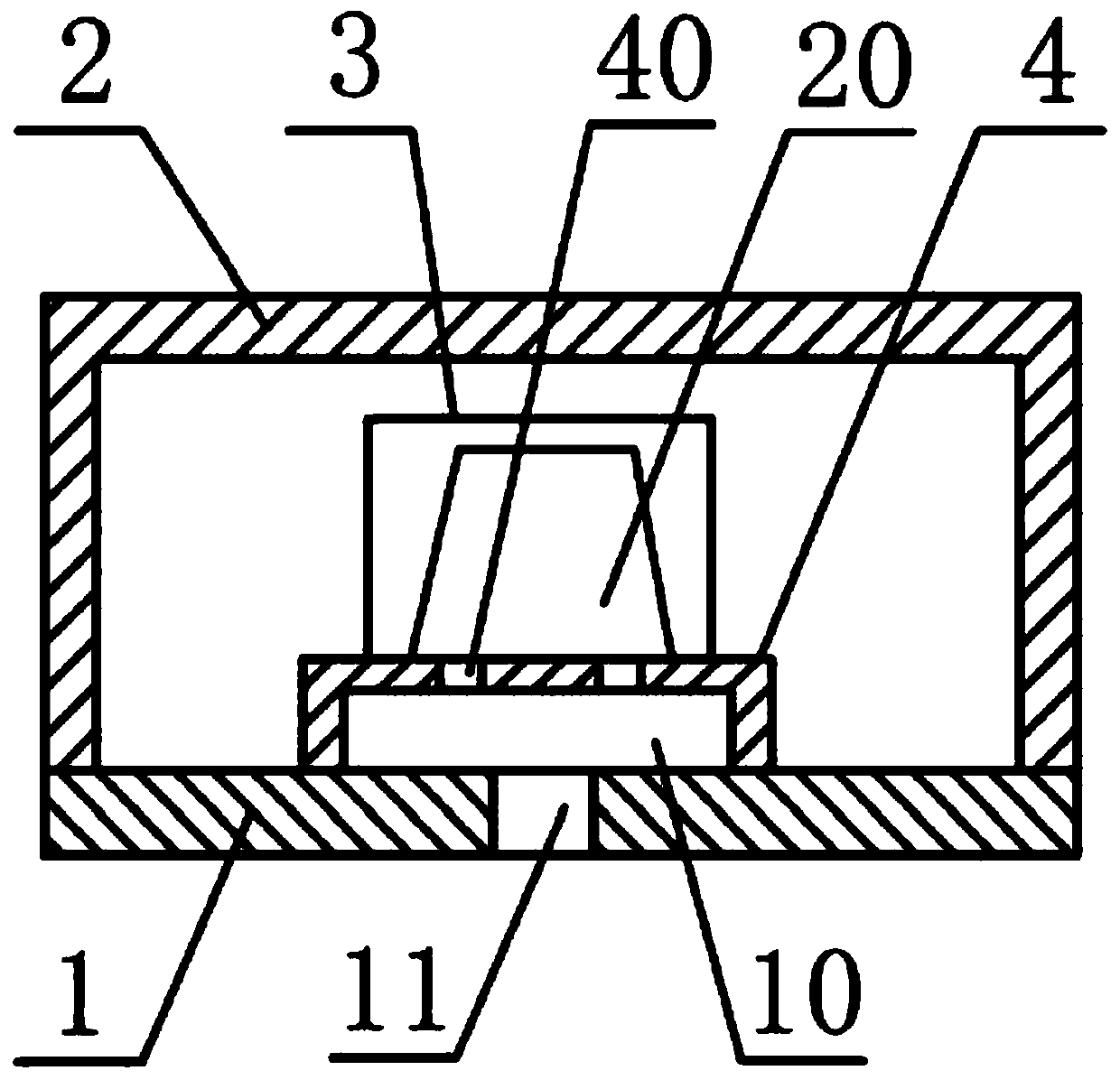

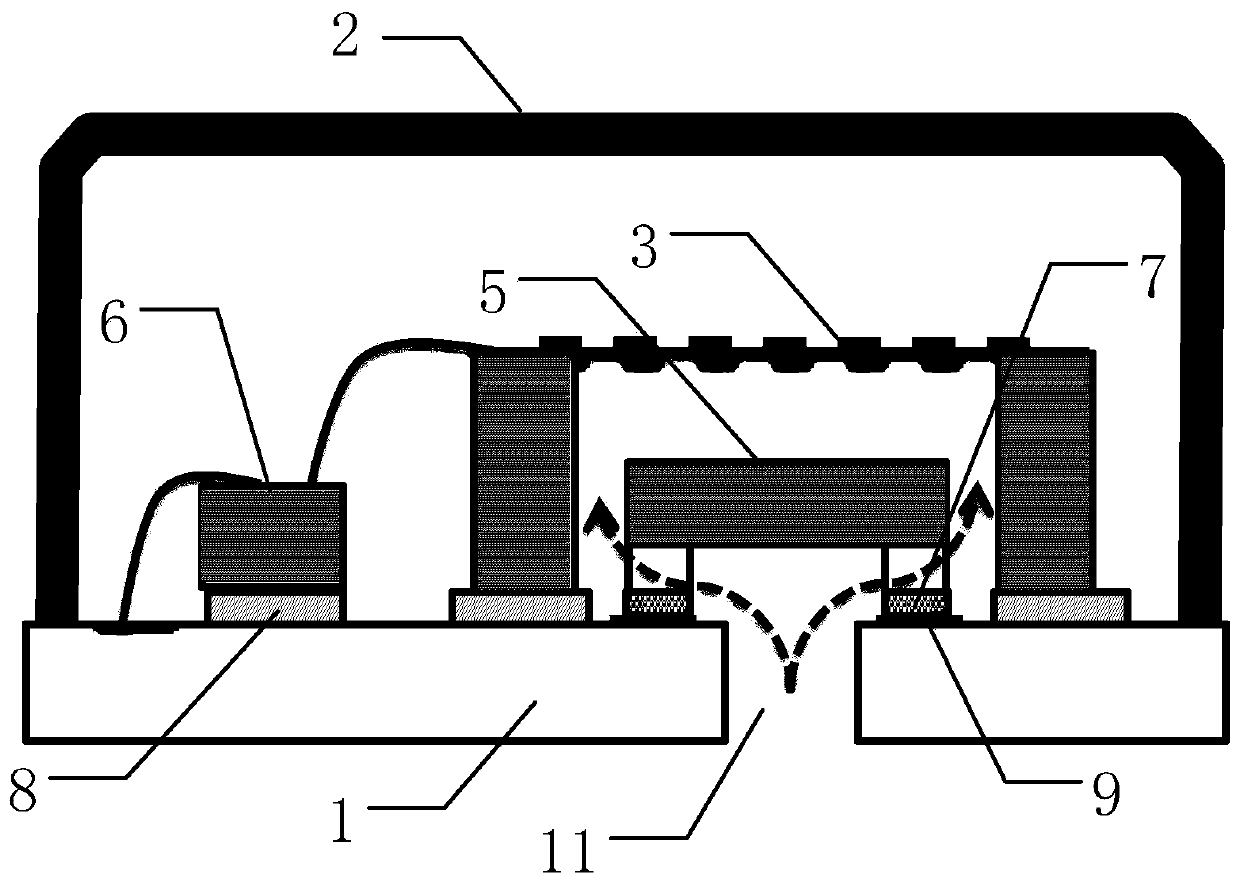

[0038] figure 2 It is a schematic diagram of a MEMS microphone structure provided by an embodiment of the present invention, such as figure 2 As shown, the MEMS microphone of the present invention includes a package structure surrounded by a PCB substrate 1 and a housing 2. The package structure is provided with a MEMS microphone 3, one end of the housing 2 is open, and the PCB substrate 1 basically seals the opening side of the housing 2. An acoustic hole 11 is provided on the PCB substrate 1 at a position corresponding to the MEMS acoustic-electric chip 3. The MEMS microphone also includes a filter 5 embedded in the back hole of the MEMS acoustic-electric chip 3. The filter 5 is connected to the PCB substrate 1. A horizontal hole is left b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com