Filter element, fluid filter assembly and assembly method thereof

A technology of filter components and filter elements, which is applied to the assembly of the components, diesel filter components, filter elements of fluid filter components, and the field of fluid filter components, and can solve complex assembly and disassembly operations, complicated joining methods, and the impact of filter element replacement, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

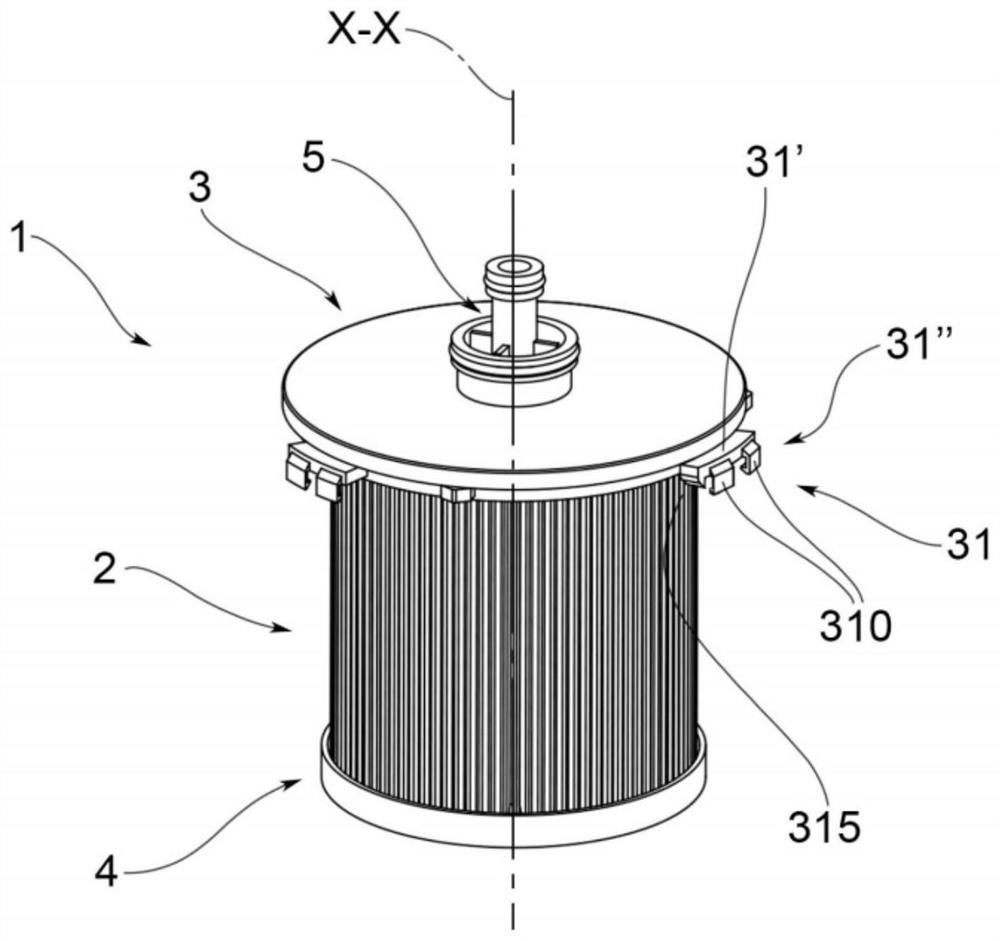

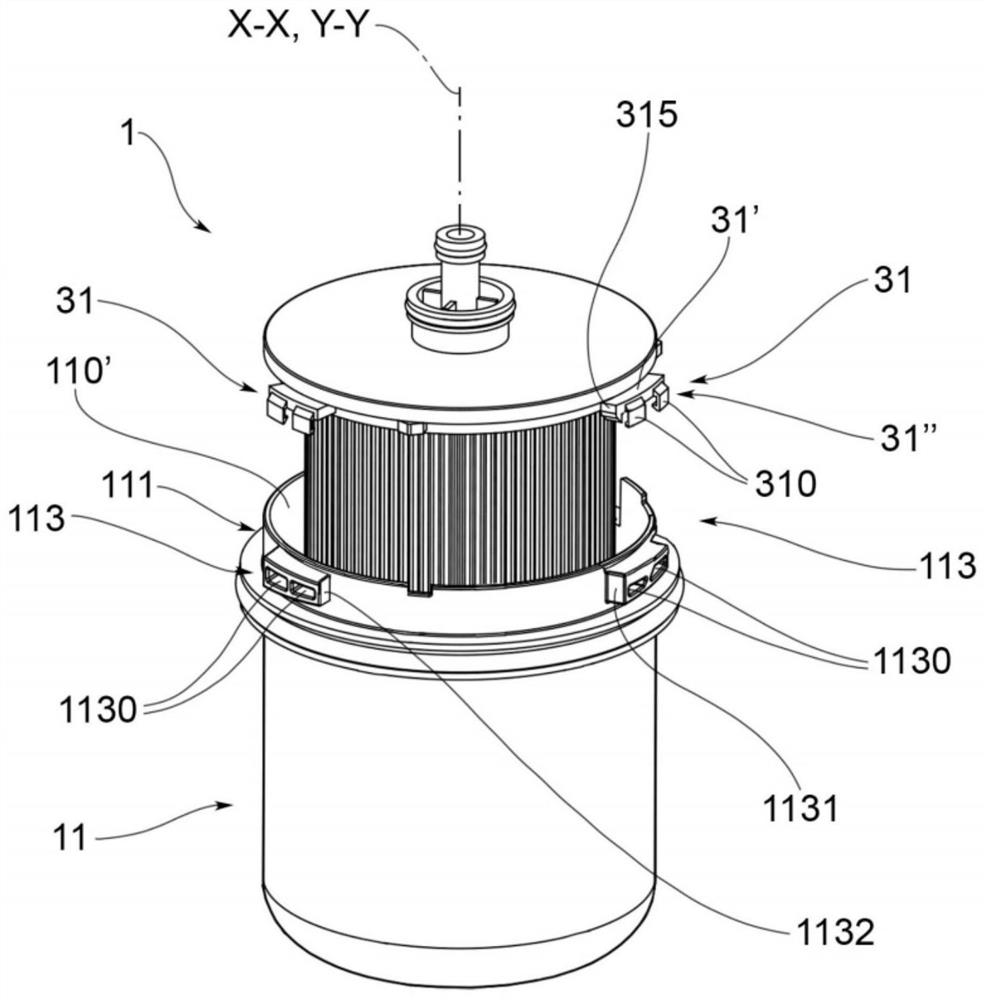

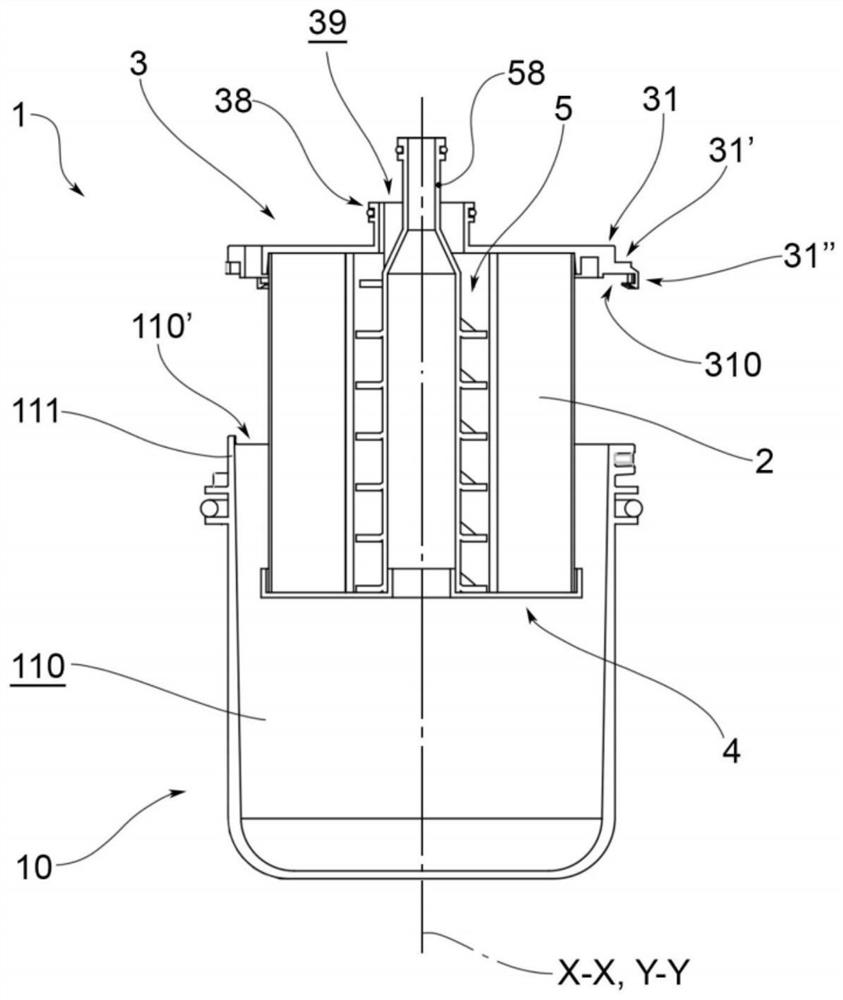

[0016] In the drawings, reference numeral 1 denotes a filter element according to a preferred embodiment of the present invention, and reference numeral 10 denotes a fluid filter assembly according to a preferred embodiment of the present invention, which includes the filter element 1 .

[0017] According to the present invention, the fluid filter assembly 10 extends along and around the main axis Y-Y, and the filter element 1 is adapted to form part of the fluid filter assembly 10 .

[0018] The fluid filter assembly 10 includes a cup body 11 and a cover body 12 that are adapted to engage with each other.

[0019] Specifically, the cup body 11 and the cover body 12 respectively include a first annular body 111 (or an inner annular body) and a second annular body 121 (or an outer annular body) at the periphery. The two annular bodies 121 are specially shaped to engage with each other. Wherein, the first annular body 111 is closer to the main axis Y-Y in the radial direction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com