Multiple graft adhesive with controllable graft degree and preparation method thereof

An adhesive and grafting degree technology, applied in the direction of grafted polymer adhesives, adhesives, adhesive types, etc., can solve the problem of high quality requirements of grafted rubber and elastomers, complex grafting process, and complex bonding process. and other problems, to achieve the effect of good bonding performance, simple bonding method and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

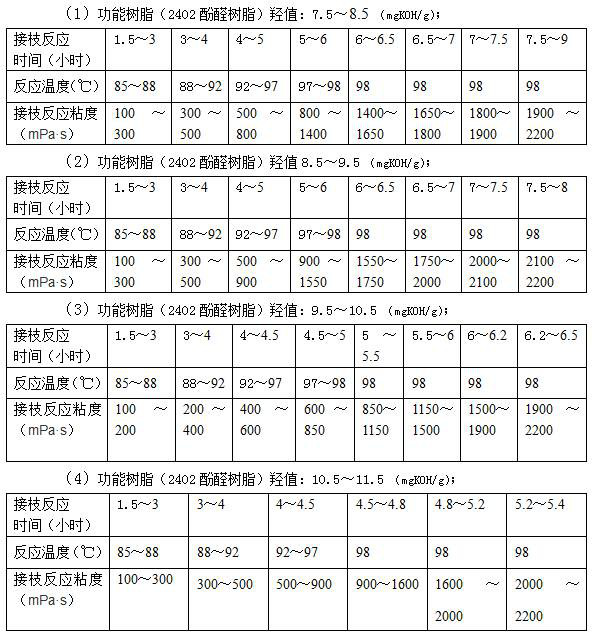

Image

Examples

Embodiment 1

[0051] Raw material formula: (parts by weight)

[0052] Toluene (TOL) 38.49

[0053] Ethyl acetate (EAC) 1.45

[0054] Solvent oil (120#) 18.15

[0055] Neoprene (SN242A) 1.27

[0056] SBS (S / B=40 / 60) 17.43

[0057] Phenolic resin (2402) (hydroxyl value: 7.5~11.5, softening point: ≥100) 2.90

[0058] Methyl methacrylate (MMA) 6.54

[0059] Butyl acrylate (BA) 1.31

[0060] Acrylic acid (AA) 0.17

[0061] Hydroxyethyl Acrylate (HEA) 0.36

[0062] Maleic anhydride 0.2

[0063] Dibenzoyl peroxide (BPO) 0.084

[0064] Inhibitor (1010) 0.29

[0065] Terpene phenolic resin 2.11

[0066] C9 resin 9.8.

[0067] Preparation method: (one-step grafting process)

[0068] In a 1000ML three-necked flask with a stirrer and a condenser, add toluene (TOL), solvent naphtha (120#), ethyl acetate (EAC) according to the above parts to start stirring, add neoprene, SBS, and heat the water to 40 ℃, stir for 1 hour, after the neoprene and SBS dissolve, the temperature reaches 50-55℃, ad...

Embodiment 2

[0084] Embodiment 2 (adopting one-step grafting process)

[0085] The SBS-chloroprene rubber viscosity graft adhesive prepared in Example 2 has the same raw material formula as that in Example 1, the difference is that the phenolic resin (2402) is not involved in the grafting reaction process but is added later, which only plays a role in grafting. For the role of tackifier, the input amount of the initiator needs to be significantly increased, otherwise the grafting reaction is difficult to realize, and the grafting reaction:

[0086] Raw material formula: (parts by weight)

[0087] Toluene (TOL) 38.49

[0088] Ethyl acetate (EAC) 1.45

[0089] Solvent oil (120#) 18.15

[0090] Neoprene (SN242A) 1.27

[0091] SBS (S / B=40 / 60) 17.43

[0092] Methyl methacrylate (MMA) 6.54

[0093] Butyl acrylate (BA) 1.31

[0094] Acrylic acid (AA) 0.17

[0095] Hydroxyethyl Acrylate (HEA) 0.36

[0096] Dibenzoyl peroxide (BPO) 0.097

[0097] Inhibitor (1010) 0.29

[0098] Terpene ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com