Assembly line processing device for drilling, milling and tapping of motor shell

A technology for processing devices and motor housings, applied in manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of high strength, inaccurate positioning, and high repair rate, and achieve the effect of avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

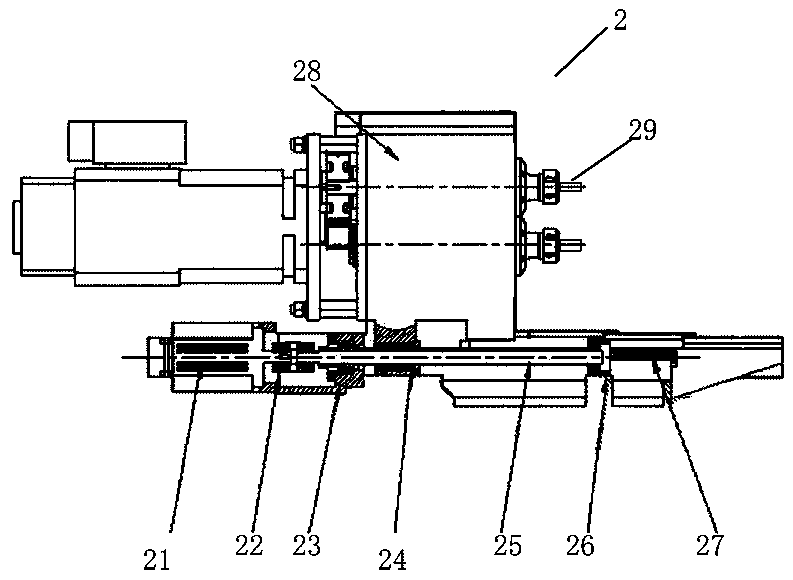

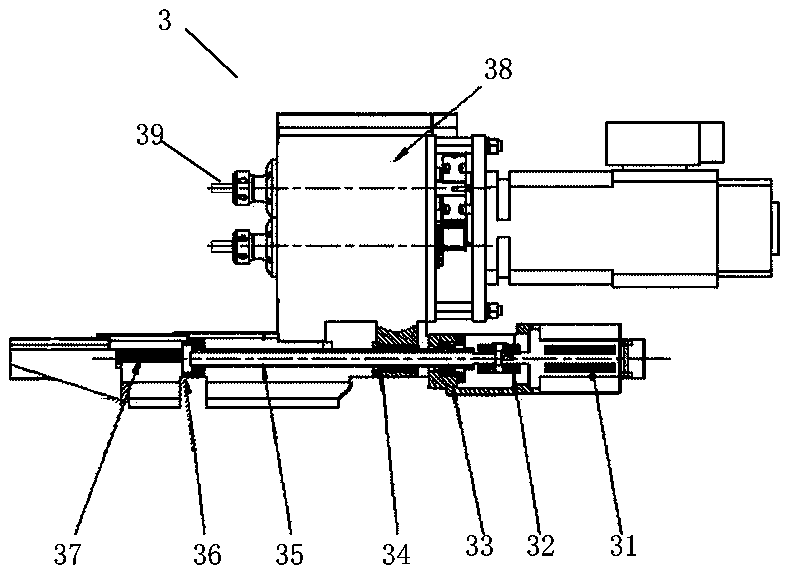

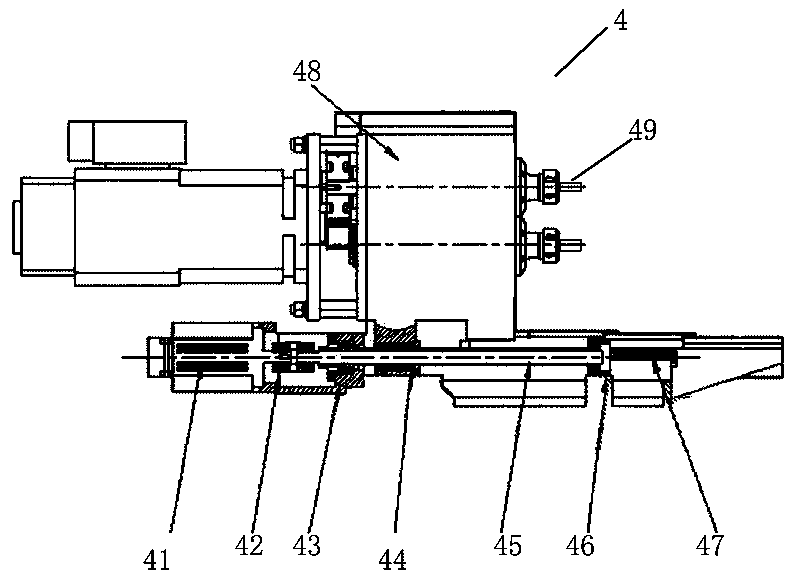

[0015] Please refer to Figure 1 to Figure 7 In the figure, a drilling, milling and tapping assembly line processing device for a motor housing includes a housing transport mechanism, a drilling system, a milling system, a tapping system, and a pressing system. The shell transport mechanism is used to transport the shell fixed on it to the corresponding system; the drilling unit 5 of the drilling system, the milling unit 3 of the milling system, and the tapping unit 4 of the tapping system are used to complete the Drilling, milling and tapping actions. The press-fit unit 5 of the press-fit system is used to fix the motor housing 6 to prevent its position from changing during the processing. The bottom of the motor housing 6 has three fixed heads 61 for fixed installation or hoisting. The motor housing 6 is fixed to the slider 13 of the housing transport mechanism 1 by bolts through the fixed heads 61 like ordinary workpiece processing.

[0016] The housing transport mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com