An Optimum Design Method for the Length of Blast Furnace Main Belt

An optimized design and belt technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as the inability to increase the feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

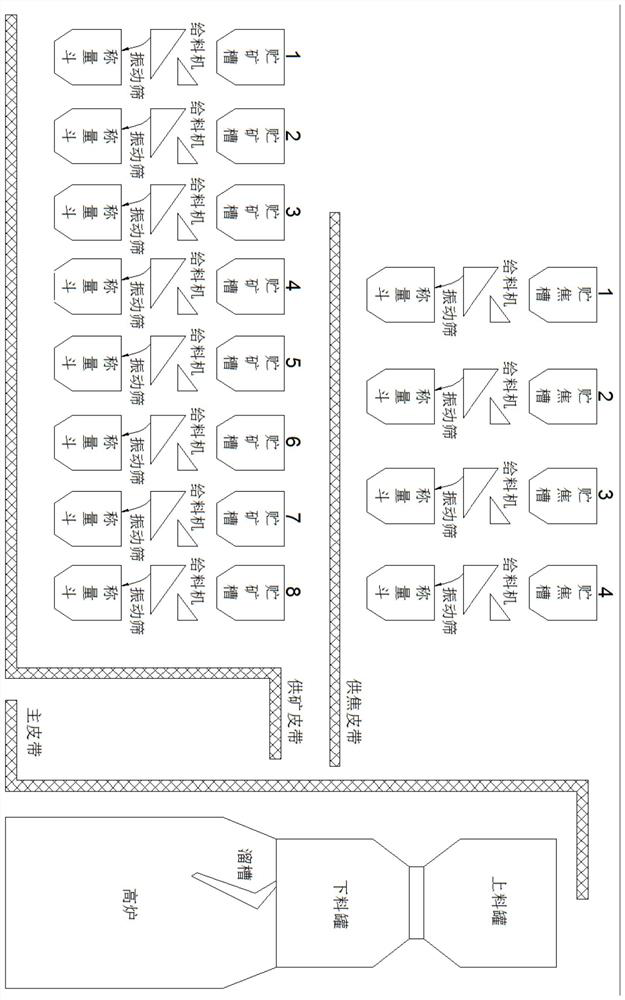

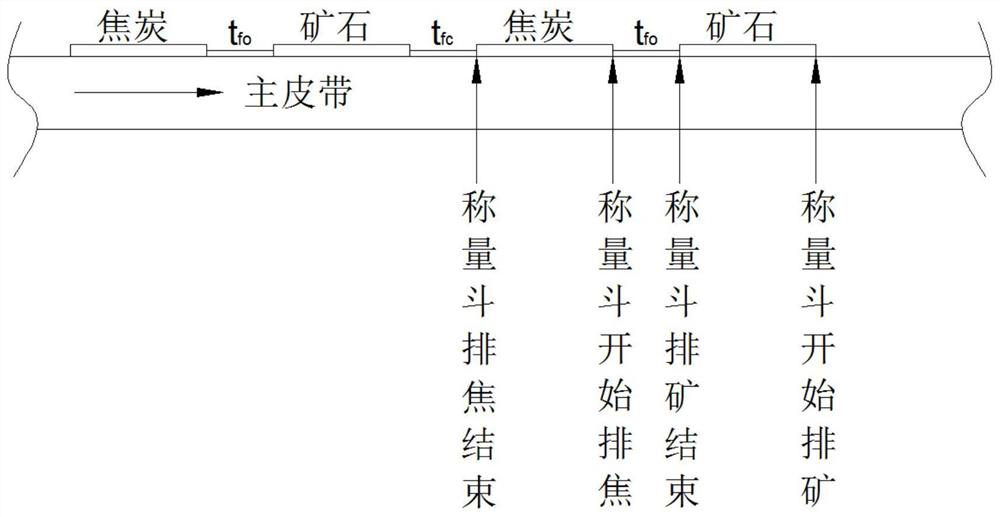

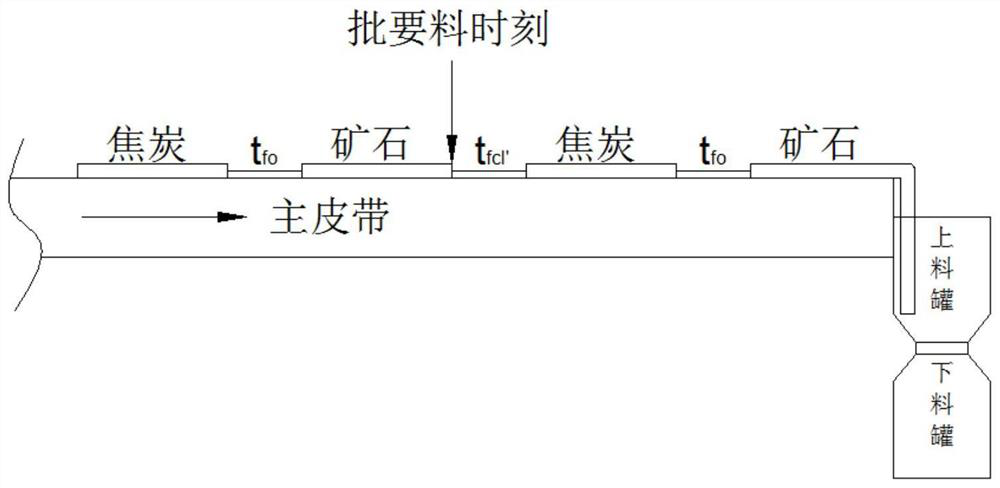

[0043] refer to Figure 1-3 , an optimal design method for the length of the blast furnace main belt, which combines the automatic feeding model of the top of the blast furnace feeding system using the main belt feeding with the feeding equipment and feeding timing, sets the starting time of the feeding signal, and passes Convert the length and speed of the main belt into time T L , calculate t according to the maximum batch weight and equipment design capacity in the design requirements o and t zo , and then the running time t of the material itself o , Material from the upper tank to the lower tank t zo , and T L Add up to get the feeding time t of the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com