Engineering geological survey method using horizontal directional drilling

A technology of horizontal directional drilling and horizontal directional drilling rig, which is applied in the directions of directional drilling, drilling equipment and methods, drilling equipment, etc., can solve the problems of not being able to truly and comprehensively reflect the characteristics of surrounding rock, high comprehensive engineering cost, and difficulty in normal implementation, etc. Achieve the effects of long-distance high-precision directional survey, high equipment intensification, and long traversal distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]In order to make the object, technical solution and advantages of the present invention clearer, the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0050] Embodiments of the present invention provide a kind of engineering geological investigation method that adopts horizontal directional drilling, comprising the following steps:

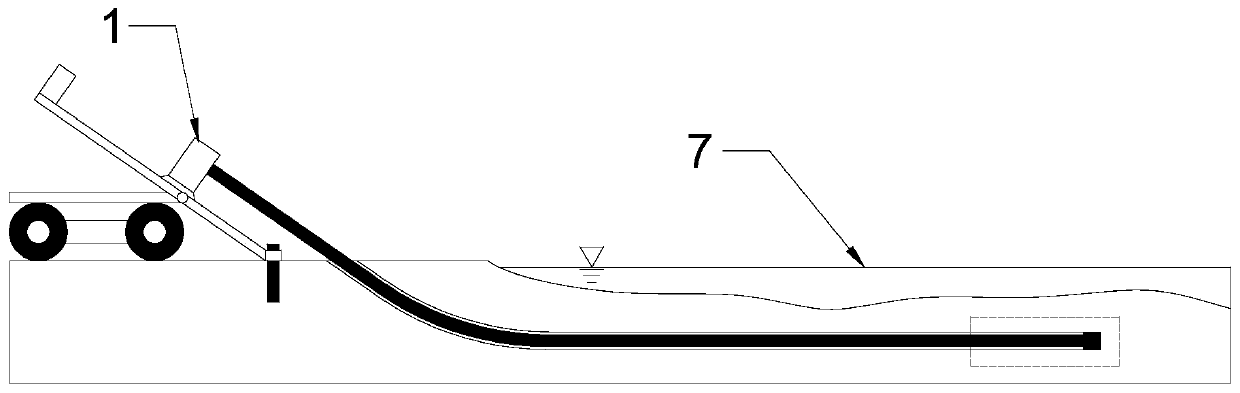

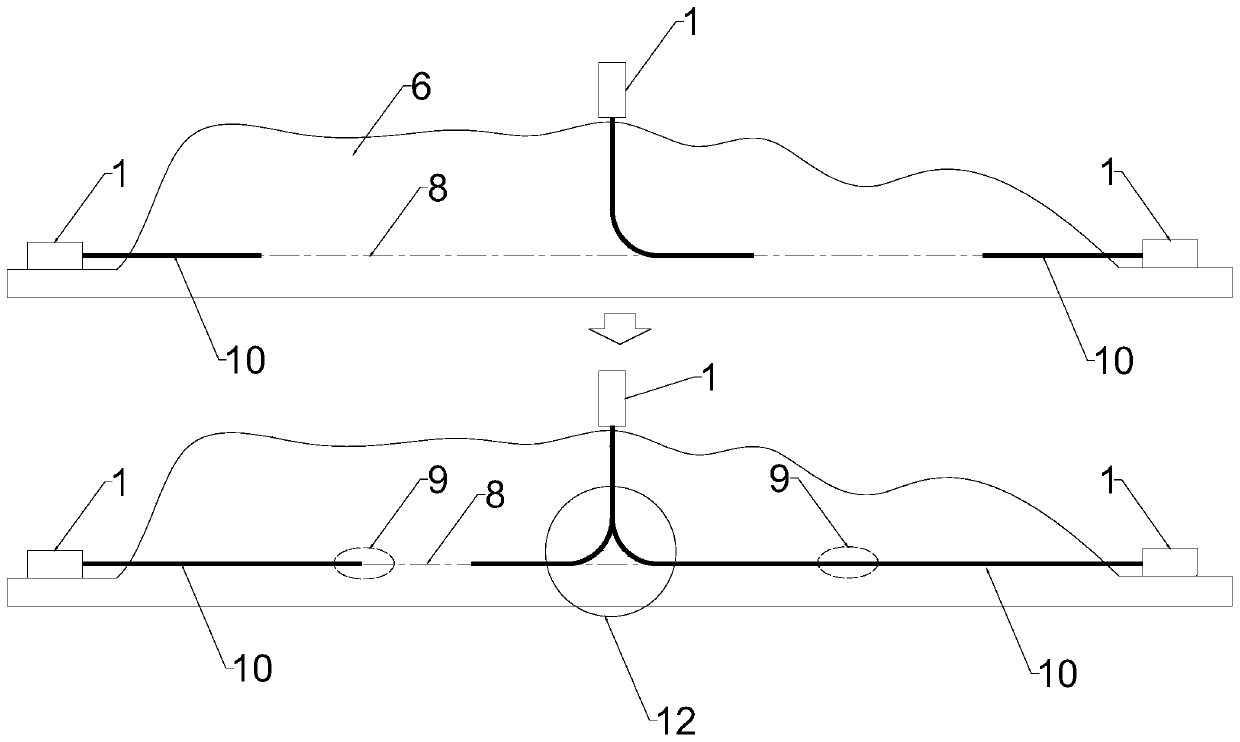

[0051] S1 arranges the horizontal directional drilling machine 1 on one side of the underground engineering, so that the horizontal directional drilling machine 1 carries out horizontal directional drilling along the axis 8 of the underground engineering;

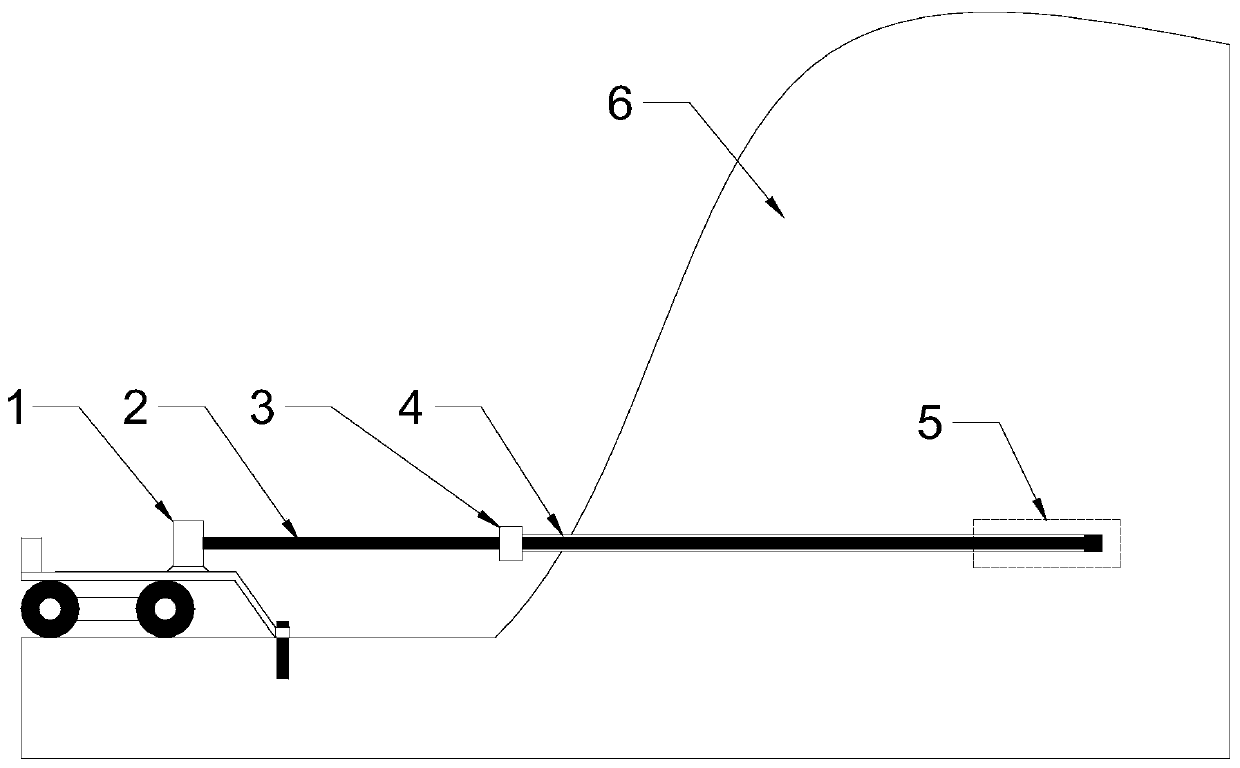

[0052] Please refer to figure 1 , when the underground project is a mountain-crossing project, during the traversing process of the mountain body 6, in order to prevent water gushing formations or broken formations, a casing 4 is set at the entrance of the horizontal directional drilling machine 1 to the borehole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com