Buffering type energy accumulator

A kind of accumulator, heavy-duty technology, applied in the direction of mechanical equipment, etc., can solve the problems of short service life of accumulator, increase of equipment maintenance and replacement cost, poor buffering effect, etc., to achieve improved service life, low maintenance and replacement cost, good cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

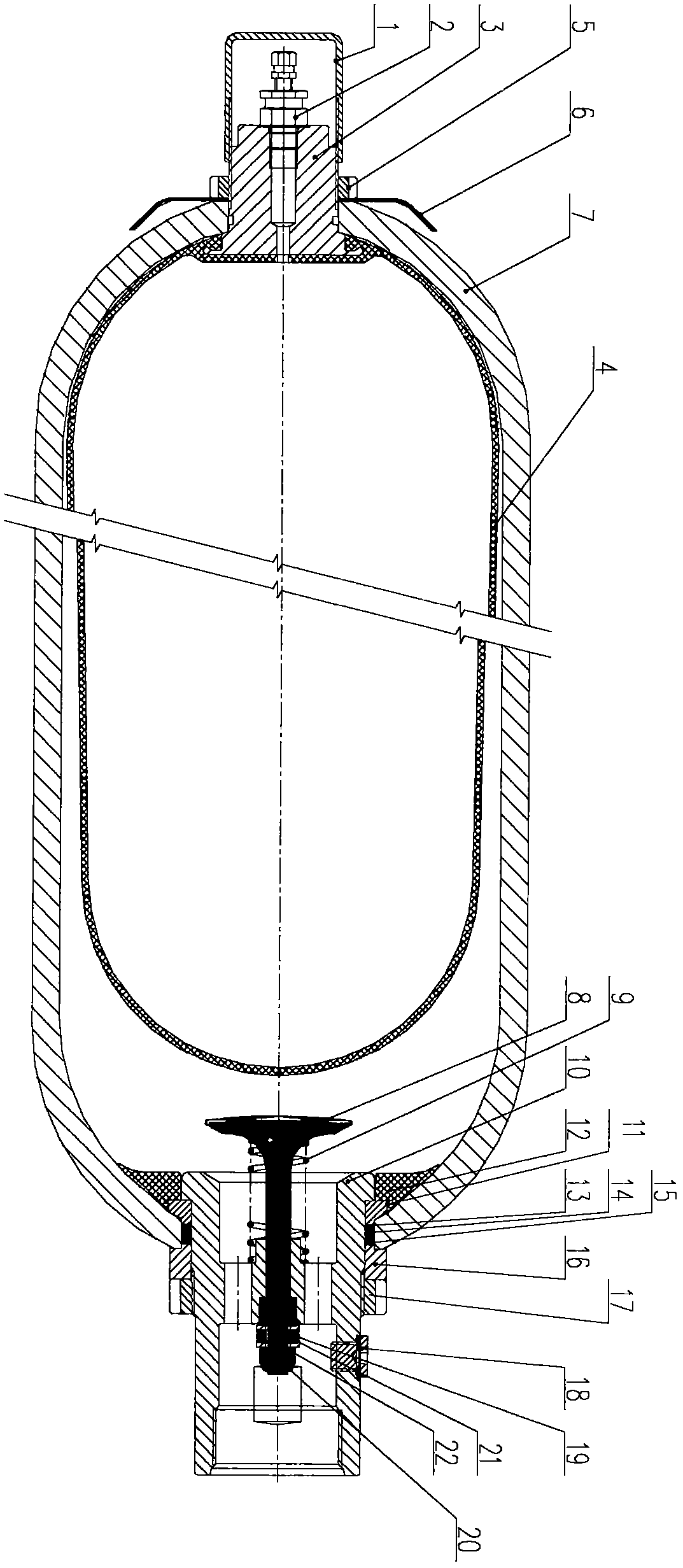

[0011] refer to figure 1 , this specific embodiment adopts the following technical solutions: buffer type accumulator, including protective cap 1, heavy-duty inflation valve 2, gas valve stem 3, capsule 4, round nut 5, nameplate 6, housing 7, fungus valve 8, Spring 9, flow valve body 10, support ring 11, rubber ring 12, metal retaining ring 13, O-ring 14, F4 retaining ring 15, pressure ring 16, lock nut 17, plug 18, piston 19, flat washer 20, Disc spring 21 and self-locking nut 22. Capsule 4 is arranged inside housing 7. One end of capsule 4 is connected to heavy-duty inflatable valve 2 through air valve stem 3. Protective cap 1 is arranged outside air valve stem 3. Air valve stem 3 passes through One end of the round nut 5 and the housing 7 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com