A easy -to -maintain -maintenance -induced gap brake

A technology without gaps and brakes, applied in the direction of brake types, axial brakes, brake actuators, etc., can solve the problems of inconvenient replacement of wearing parts, cumbersome disassembly process, superposition, etc., to ensure machining accuracy and operation process Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

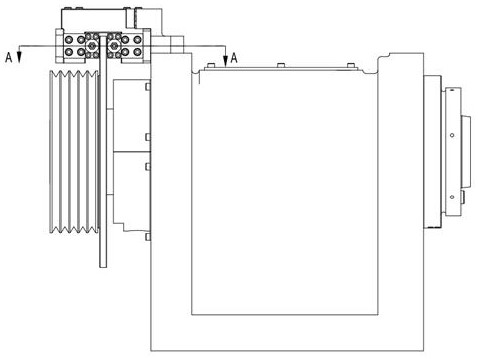

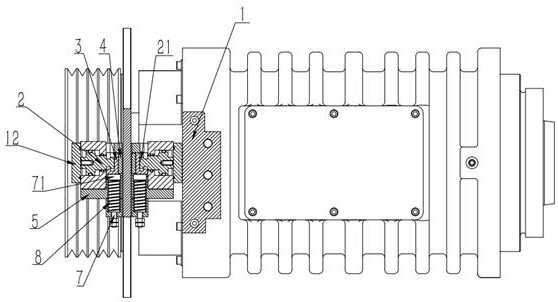

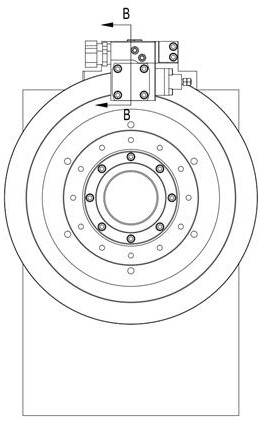

[0021]Embodiment: An easy-to-maintain type gapless brake, including a mounting bracket 1 for fixing on a machine tool, a pushing device arranged oppositely is installed on the mounting bracket 1, and the opposite side of the pushing device has a center line and a The piston rod 2 that can move back and forth along the relative direction, the top of the piston rod 2 is equipped with a brake block for friction braking the machine tool spindle brake disc 9, it is characterized in that: the distal end of the piston rod 2 along the piston rod The center line protrudes outward to form a limit head 21. The diameter of the limit head 21 is larger than the diameter of the piston rod 2. The brake block includes a connection block 3 connected with the piston rod 2. An inverted T is opened on one side of the connection block 3. T-shaped chute 31, the limit head 21 slides into the transverse groove in the inverted T-shaped chute 31 so that the connecting block 3 is connected to the piston r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com