Dynamic monitoring system for premixed concrete quality

A dynamic monitoring and concrete technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of many people needed, cutting corners, and large workload, reducing the use of labor, improving detection efficiency, The effect of facilitating centralized supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

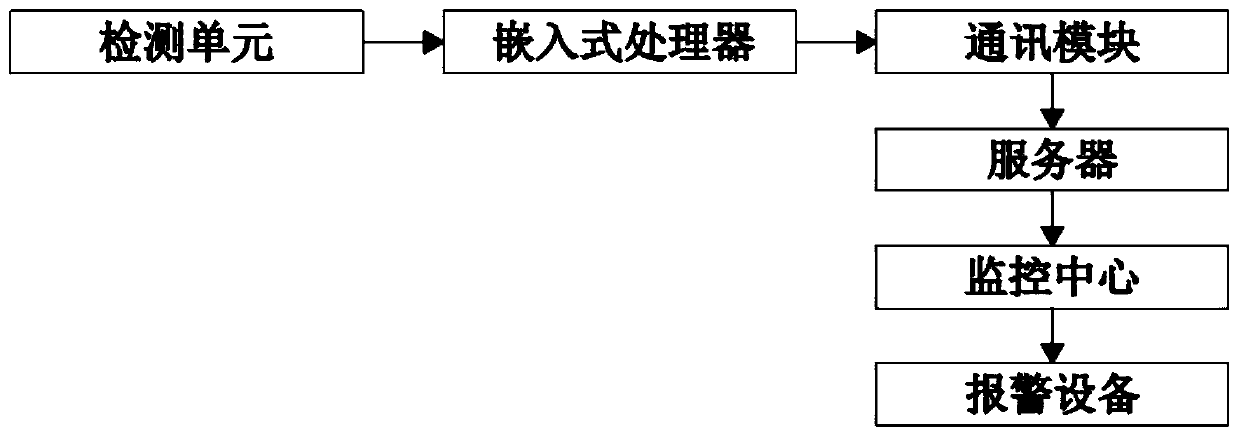

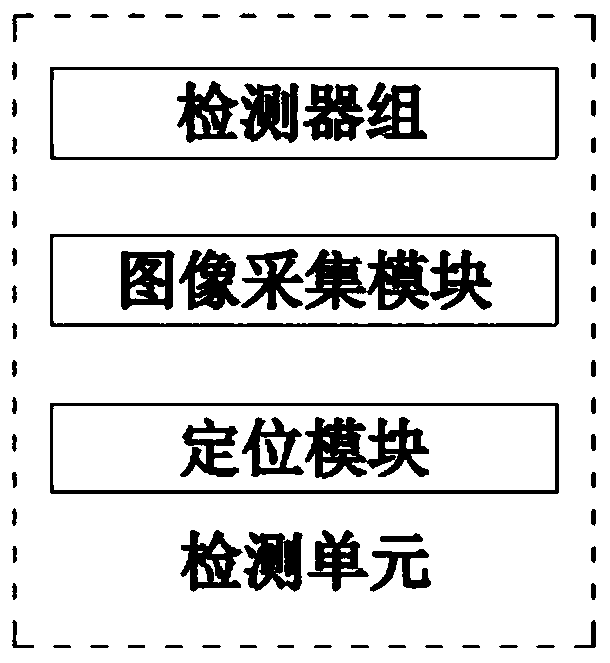

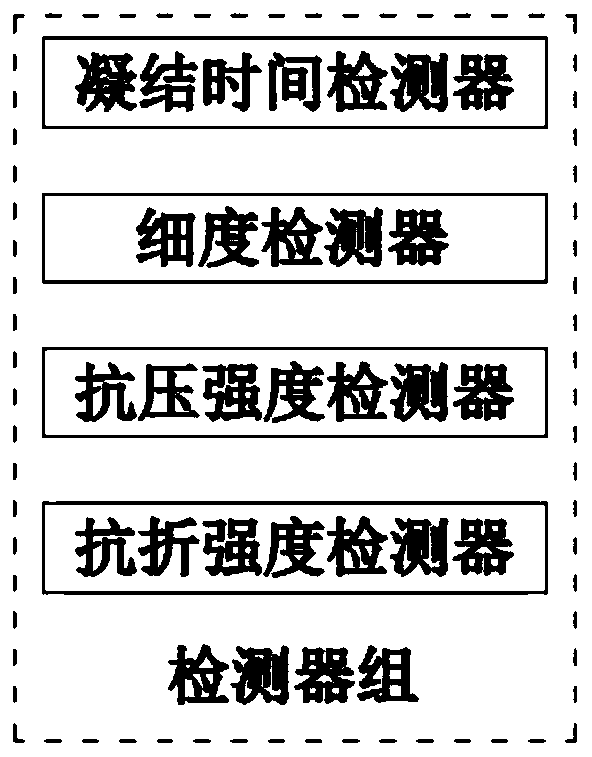

[0030] see Figure 1-3 , the present invention provides a technical solution: a dynamic monitoring system for the quality of pre-mixed concrete, including a detection unit, an embedded processor, a communication module, a server, a monitoring center and an alarm device, the output terminal of the detection unit is connected to the embedded processing The input end of the device establishes a connection, the output end of the embedded processor establishes a connection with the input end of the communication module, the output end of the communication module establishes a connection with the server, and the output end of the server establishes a connection with the monitoring center, so The output terminal of the monitoring center is connected with the alarm equipment;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com