Goods sorting method, control system and cargo sorting system

A control system and cargo technology, applied in the direction of control/regulation system, non-electric variable control, vehicle position/route/height control, etc., can solve problems such as difficult application, inconvenient and flexible deployment of conveyor lines, and low picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

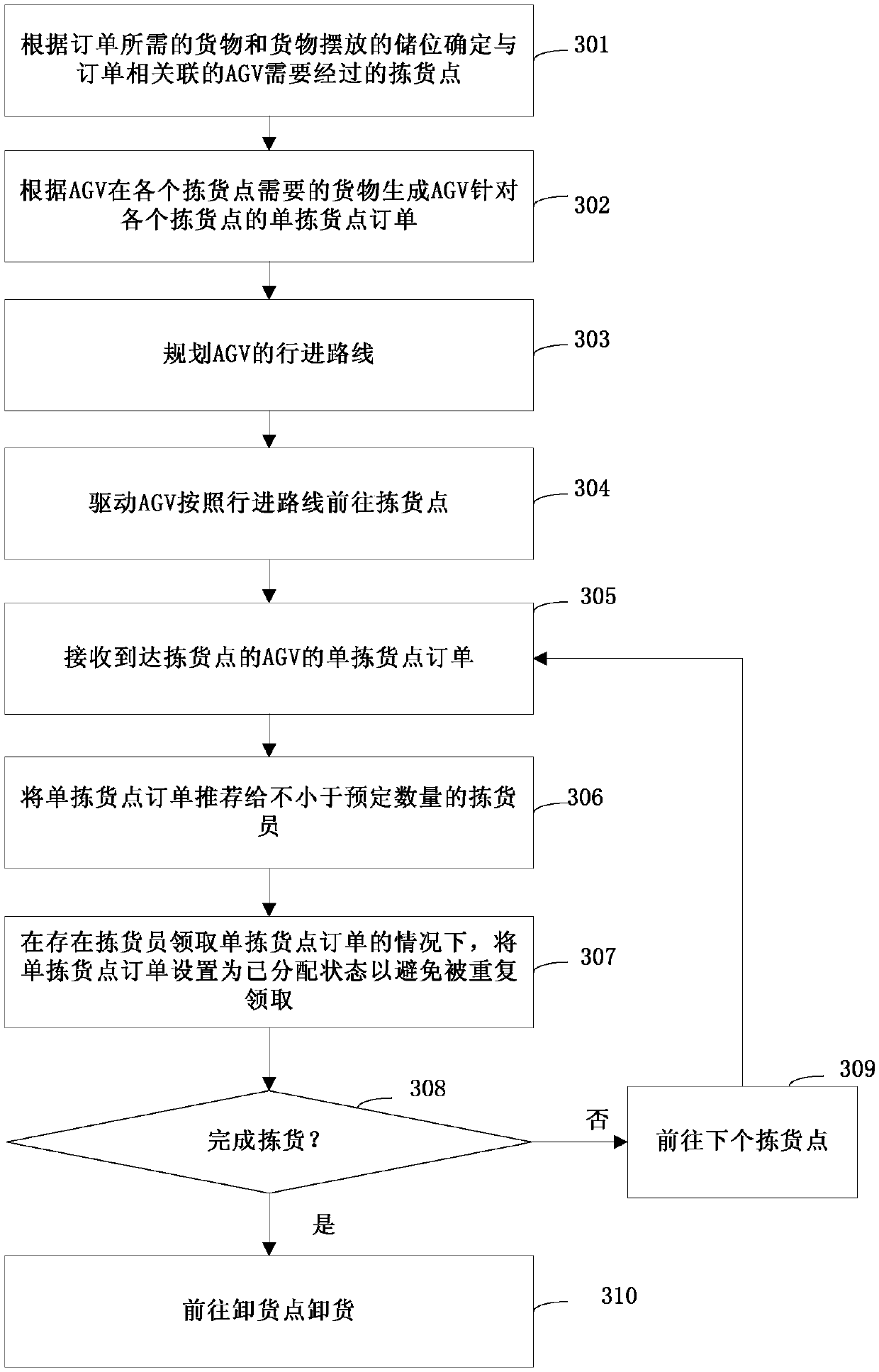

[0040] The technical solution of the present disclosure will be described in further detail below with reference to the drawings and embodiments.

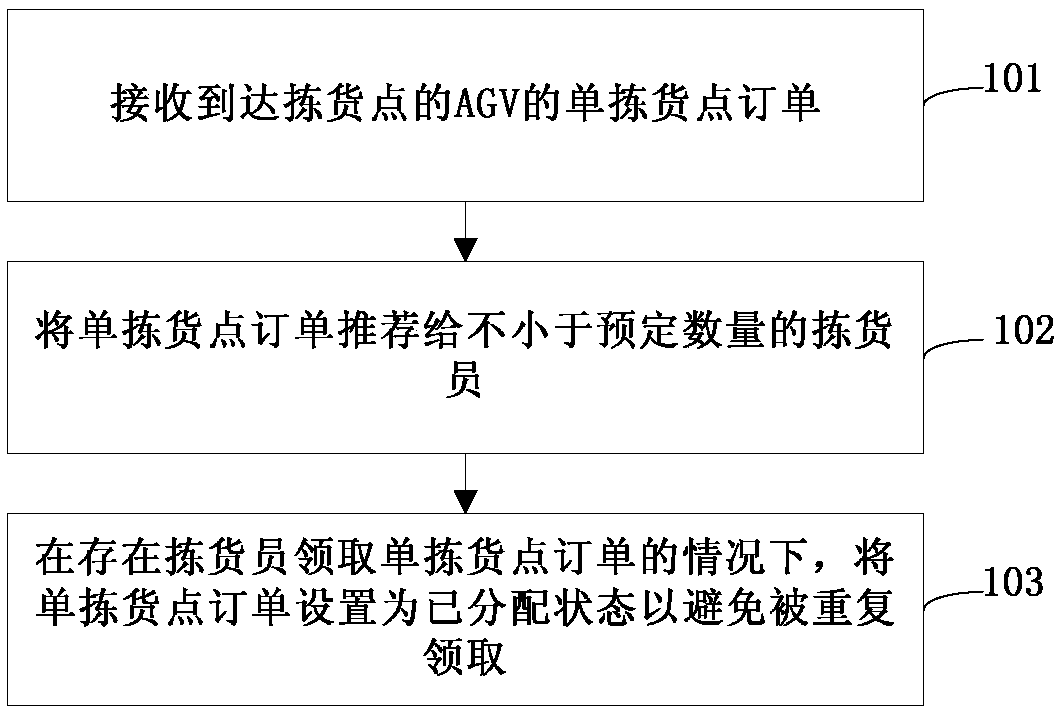

[0041] The flowchart of an embodiment of the cargo sorting method of the present disclosure is as follows figure 1 shown.

[0042]In step 101, a single picking point order of an AGV arriving at the picking point is received, and the single picking point order includes information on goods belonging to a single picking point in the order associated with the AGV. In one embodiment, the information of the goods may include information such as the name of the goods, model, barcode, two-dimensional code and / or other goods identification, and may also include the required quantity of the goods.

[0043] In one embodiment, a single AGV can be associated with an order, and the single-picking point order includes the goods information that the AGV needs to belong to an order at a single picking point. In this way, when the AGV completes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com