Grip dynamometer with elastic stabilizing units and palm width adjusting function, and application method of grip dynamometer

An elastic, stable and wide-adjustable technology, applied in the field of hand dynamometers, can solve the problems of limited reproducibility, inconsistent results, and large volume of measuring instruments, and achieve the effects of reducing inaccurate data collection, easy to carry and grasp, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

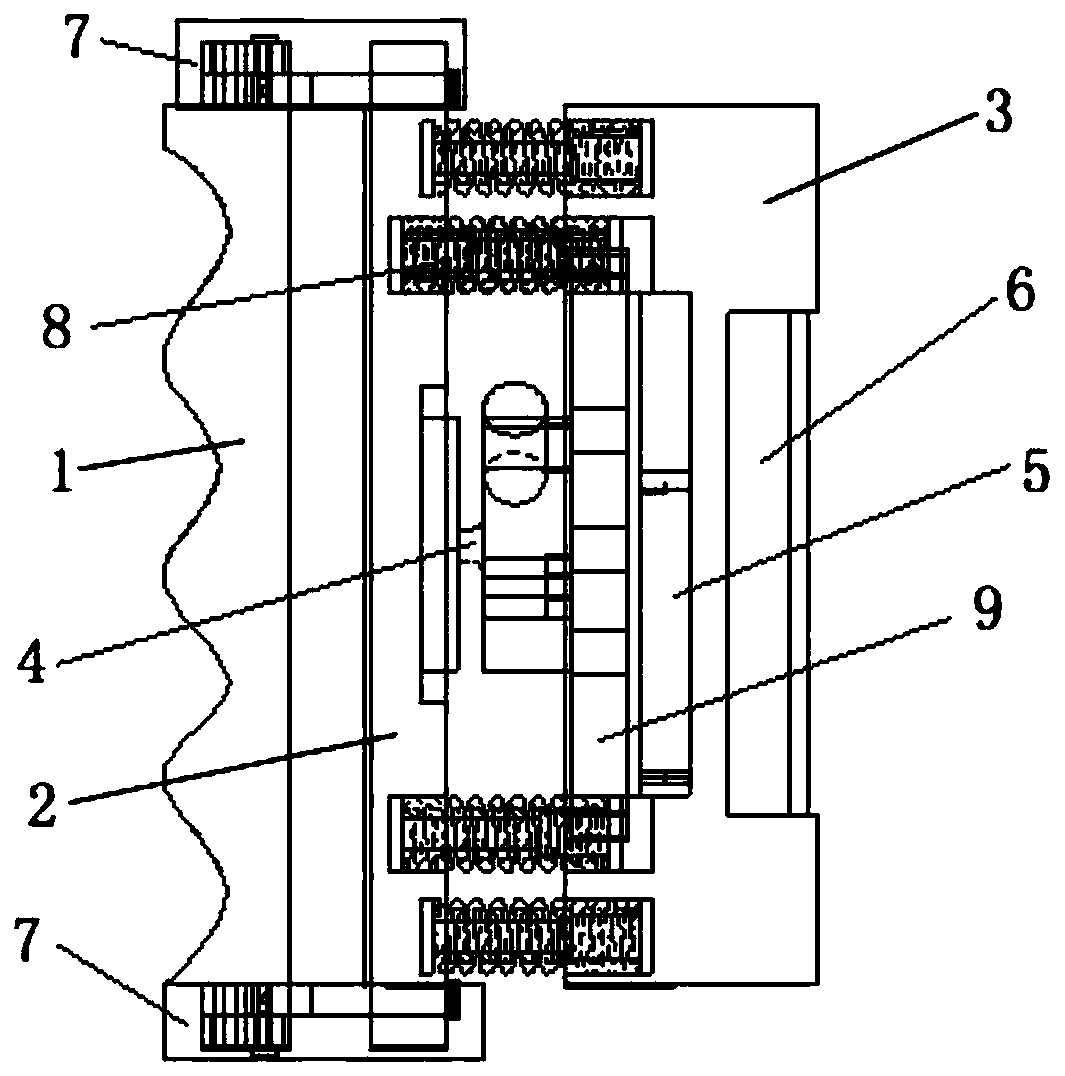

[0036] Such as Figure 1-4 As shown, the grip meter of the present invention with elastic stabilization unit and palm width adjustment function includes a grip 1, a connecting plate 2, a substrate 3, a pressure sensor 4, an integrated circuit board 5 and a battery 6;

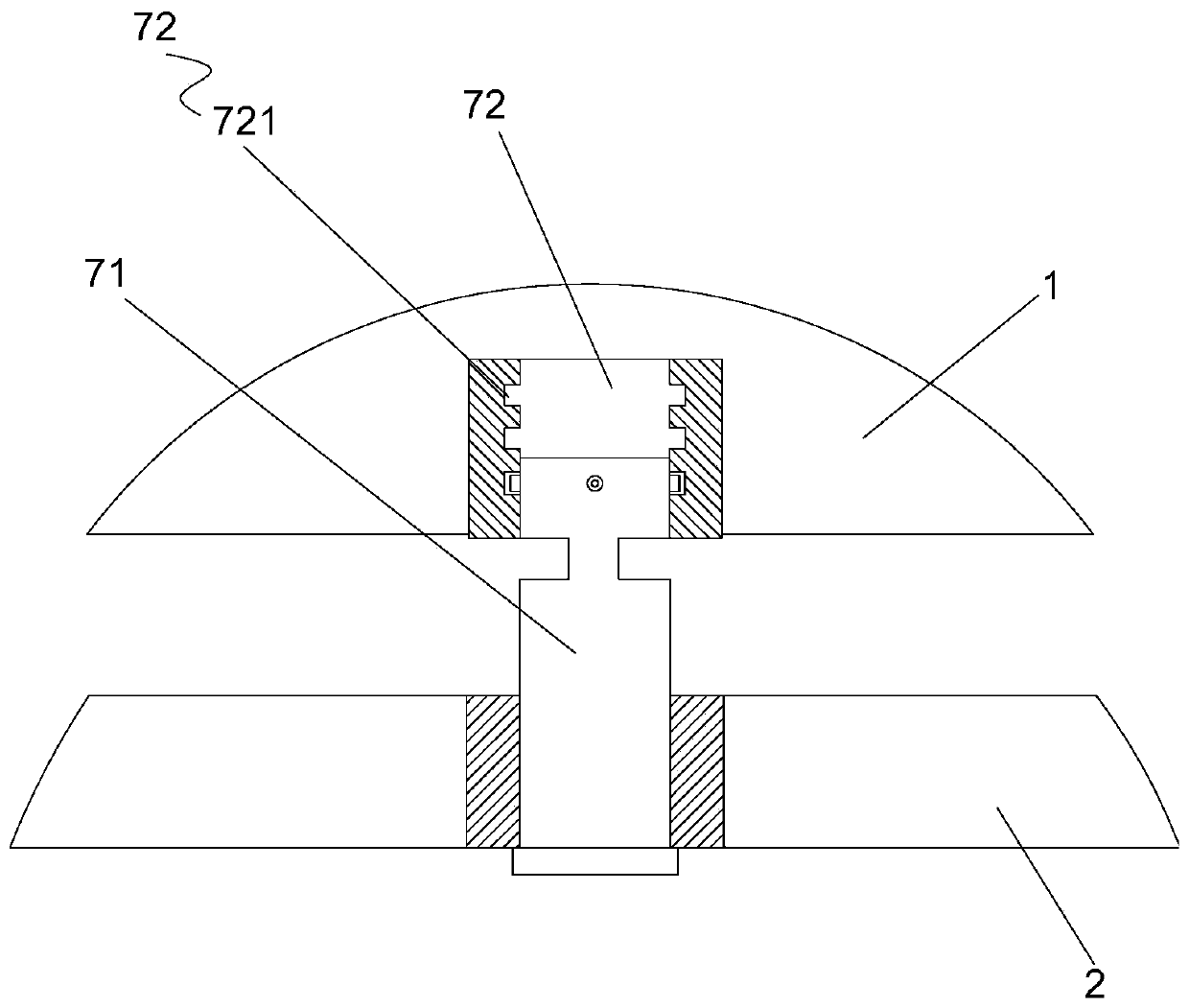

[0037] The two sides of the connecting plate 2 are respectively connected to the grip 1 through a palm width adjusting mechanism 7, and the palm width adjusting mechanism 7 is used to adjust the size of the interval between the grip 1 and the connecting plate 2;

[0038] The pressure sensor 4 is placed in the middle of the connecting plate 2 and the base plate 3, the bottom of the pressure sensor 4 is fixed on the inner surface of the base plate 3, and the detection head of the pressure sensor 4 rests on the inner surface of the connecting plate 2;

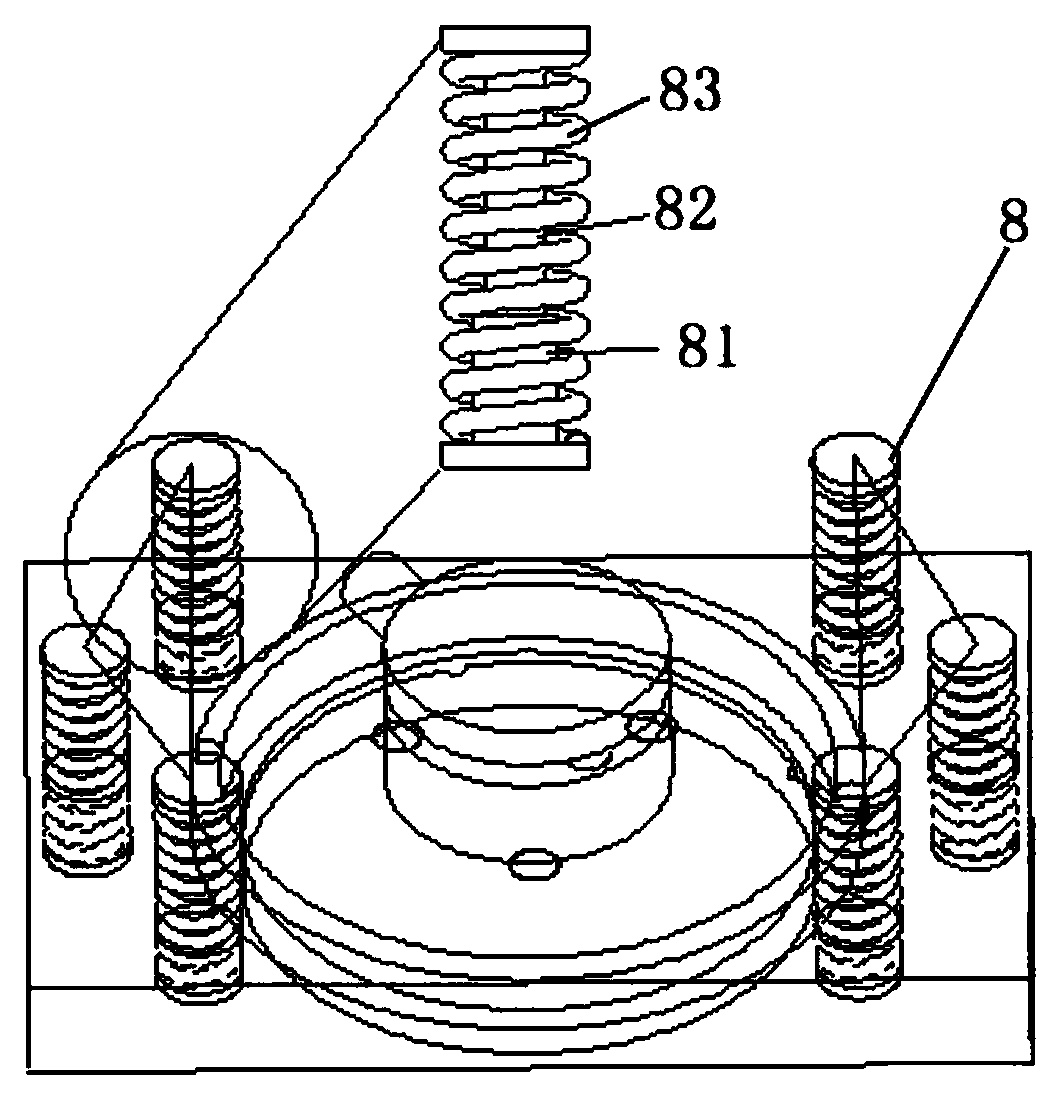

[0039] The connecting plate 2 and the base plate 3 are directly connected with two sets of elastic stable components symmetrically arranged on both sides of the pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com