Self-charging non-woven fabric with spray-loaded micro-nano particles and its preparation method and application

A micro-nano particle, self-charging technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of difficult molding, poor electrostatic durability, and high filtration resistance, achieve high ability to store electrostatic charges, increase load The effect of fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

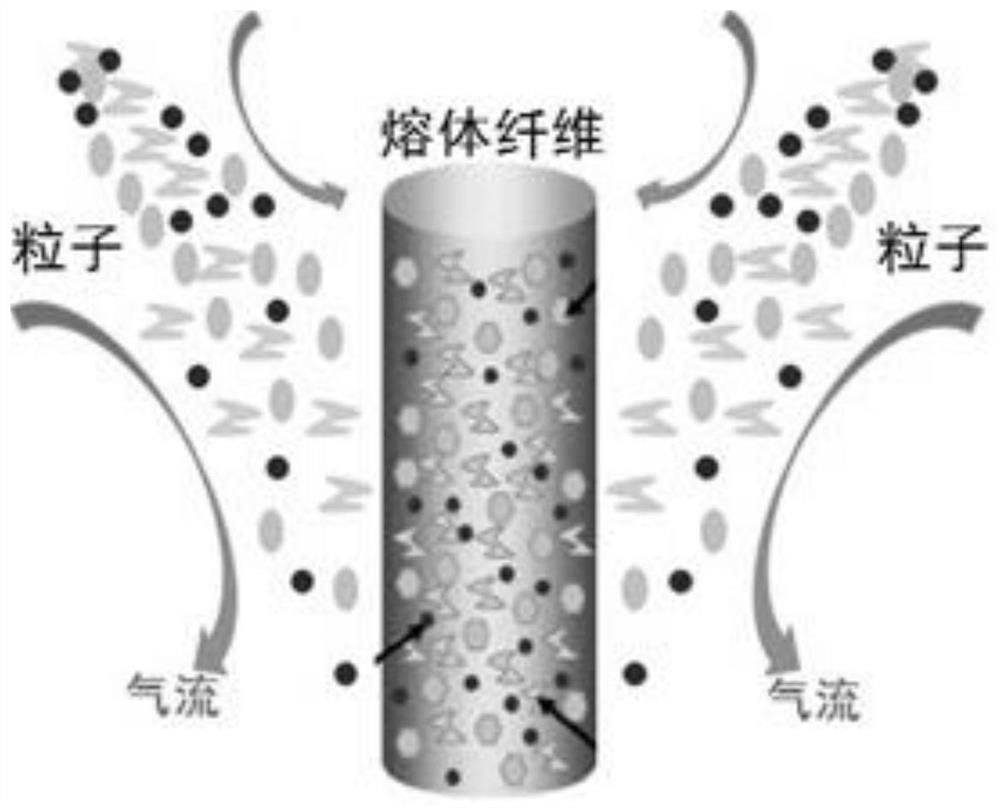

[0039] A self-charging non-woven fabric loaded with micro-nano particles by spraying, which is composed of polypropylene fibers and polytetrafluoroethylene micro-nano particles loaded on the surface of the polypropylene fibers. The average particle size of the polytetrafluoroethylene is 300nm. Prepared by melt-blown method, the details are as follows:

[0040] S1. Melt the dried polypropylene spinning raw material in a twin-screw extruder and spray it out from the spinneret hole for melt spinning;

[0041] Among them, the polypropylene melt extrusion temperature is 240°C, the spinneret aperture is 0.16mm, and the receiving distance is 15cm;

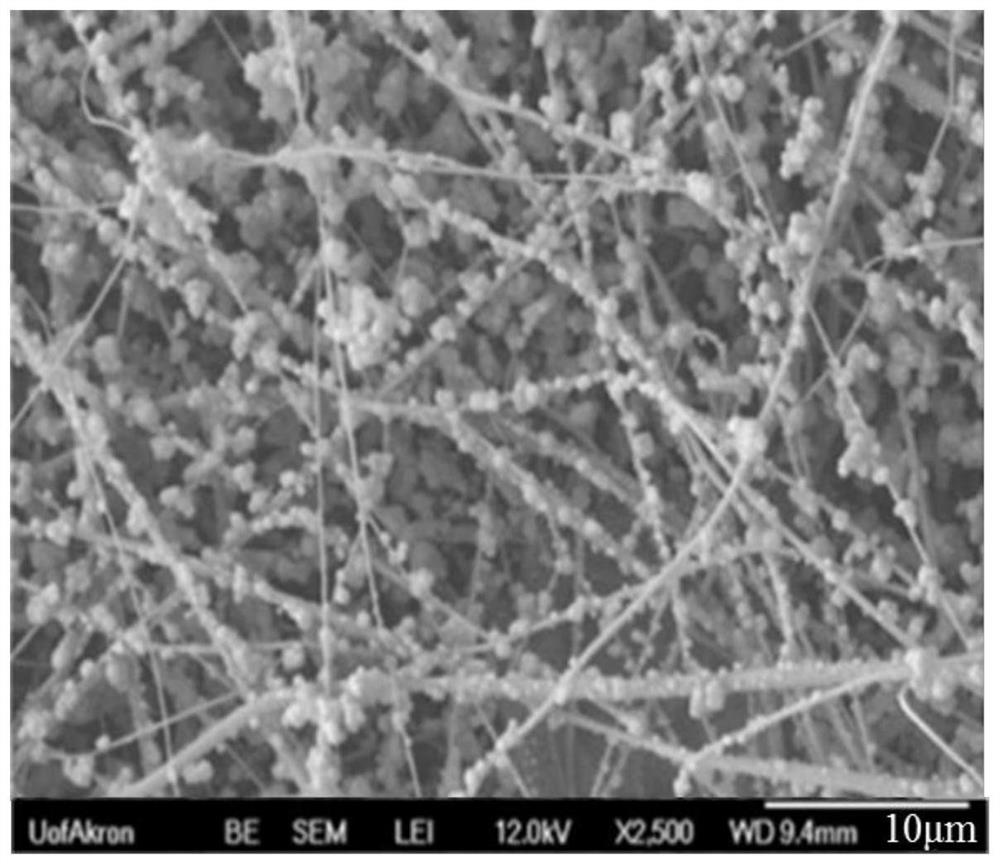

[0042] S2. The polymer melt fiber is sprayed with the melt-blown air flow dispersed with polytetrafluoroethylene micro-nano particles, so that the polytetrafluoroethylene micro-nano particles are sprayed and loaded onto the surface of the polypropylene fiber melt along with the air flow to obtain a surface load Polypropylene fibers of po...

Embodiment 2~16

[0049] The spray-loaded self-charging non-woven fabrics provided in Examples 2-16 are all composed of polypropylene fibers and polytetrafluoroethylene micro-nano particles loaded on the surface of the polypropylene fibers. Compared with Example 1, the difference lies in that the particle size and preparation conditions of polytetrafluoroethylene micro-nano particles are shown in Table 1, and the others are basically the same as in Example 1, and will not be repeated here.

[0050] Table 1 Example 2~16 particle size and preparation conditions of polytetrafluoroethylene micro-nano particles

[0051]

[0052]

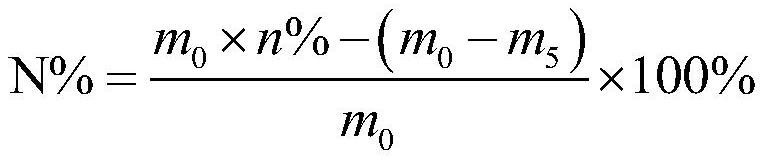

[0053] The load and load fastness of the self-charging non-woven fabrics of blown-loaded micro-nano particles provided in Examples 2-16 are shown in Table 2, as can be seen from Example 1 and Examples 2-4, with the As the particle size of fluoroethylene micro-nano particles increases, the loading capacity gradually decreases. This is because when the particle size of...

Embodiment 17

[0063] A self-charging non-woven fabric loaded with micro-nano particles by spraying, which is composed of polyethylene fibers and polytetrafluoroethylene micro-nano particles loaded on the surface of polyethylene fibers. The average particle diameter of the polytetrafluoroethylene is 300nm. Compared with Example 1, the preparation method is different in that the polyethylene melt extrusion temperature is 230° C., and the others are roughly the same as Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com