Electret nonwoven filter material with cavity structure and preparation method thereof

A filter material and electret technology, applied in the direction of non-woven fabrics, separation methods, filtration separation, etc., can solve the problems of easy loss of charge, prolong the static charge decay period of filter materials, and difficulty in guaranteeing coating fastness, etc., to achieve improved persistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

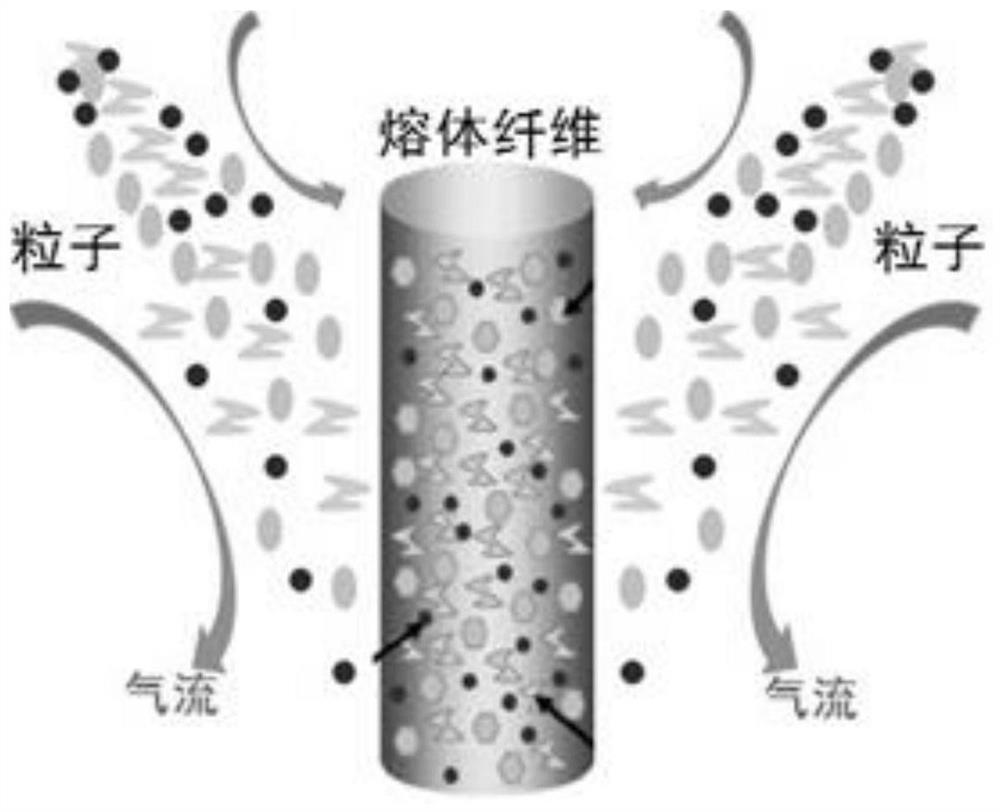

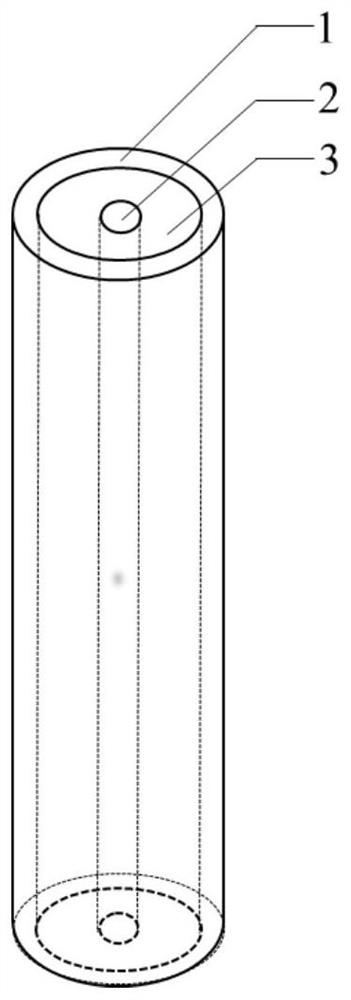

[0037] An electret nonwoven filter material with a cavity structure, which is composed of a polypropylene fiber tube loaded with polytetrafluoroethylene on the outer layer and polyethylene terephthalate nanofibers nested in the fiber tube. The average particle diameter of polytetrafluoroethylene is 300nm, and preparation method is as follows:

[0038] S1. Polypropylene is melted to obtain melt spinning raw material a, and thermodynamically incompatible polyethylene terephthalate and cellulose acetate butyrate are melt blended at a mass ratio of 1:9 to obtain melt spinning raw material b;

[0039] S2. The melt-spinning raw material a and the melt-spun raw material b described in step S1 are ejected from the dual-channel coaxial spinneret holes for melt spinning;

[0040] Wherein, the melt-spinning raw material a is ejected from the outer spinneret hole, and the melt-spun raw material b is ejected from the inner spinneret hole; the diameter of the inner spinneret hole of the dou...

Embodiment 2~7

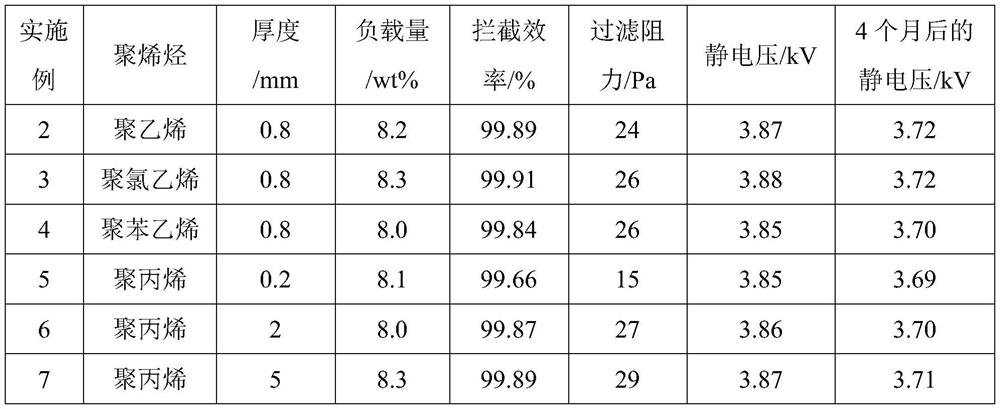

[0048] Compared with Example 1, the electret nonwoven filter material with a cavity structure provided by Examples 2 to 7 differs in that the type of spinning raw material a is shown in Table 1, and the others are basically the same as in Example 1. Same, no more details here. Table 1 also shows the thickness, load capacity and filtration performance related parameters of the electret nonwoven filter materials prepared in Examples 2-7.

[0049] From the performance test results of the electret nonwoven filter materials prepared in Example 1 and Examples 2-7, it can be seen that when the preparation process parameters are basically unchanged, the loading capacity of polytetrafluoroethylene does not change much. When the thickness remains the same and only the type of polyolefin is changed, the static voltage and static voltage persistence of the filter material do not change much, so the interception efficiency and filtration resistance are not much different. From Example 1 a...

Embodiment 8~12

[0053] Compared with Example 1, the electret nonwoven filter material with cavity structure provided by Examples 8 to 12 differs in that the composition of the spinning raw material b is shown in Table 2, and the others are basically the same as in Example 1. Same, no more details here. The electret nonwoven filter materials prepared in Examples 8-12 all have a thickness of 0.8 mm.

[0054] From the performance test results of the electret nonwoven filter materials prepared in Example 1 and Examples 8-12, it can be seen that as the mass ratio of polyester and matrix increases, the diameter of the polyester fiber filaments in the inner layer increases gradually , the static voltage and static voltage persistence gradually decrease, resulting in a gradual decrease in the interception efficiency of the filter material, and a gradual increase in the filtration resistance. This is because when the matrix content decreases, the space occupied by the matrix decreases, and after solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com