A kind of self-cleaning polyester fiber for bedding filling and preparation method thereof

A polyester fiber, self-cleaning technology, used in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of unsuitable photocatalytic mass production applications, expensive magnetron sputtering equipment, and high use costs. The effect of inhibiting the growth of bacteria, improving the load fastness and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

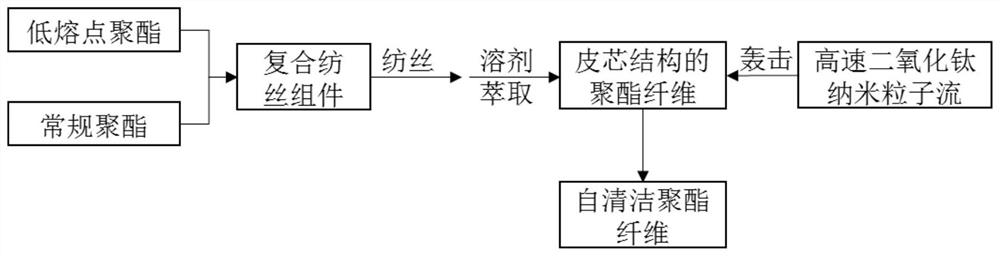

Method used

Image

Examples

Embodiment 1

[0041] A kind of self-cleaning polyester fiber for bedding filling, comprising the polyester fiber of the skin-core structure and titanium dioxide nanoparticles with a particle diameter of about 60nm loaded in the skin layer of the skin-core structure, the skin layer of the skin-core structure is A low-melting polyester with a melting point of 110°C and a thickness of about 100 nm. The core layer of the skin-core structure is polyethylene terephthalate (PET); the titanium dioxide nanoparticles form protrusions on the surface of the skin layer, so The protrusions endow the surface of the cortex with superhydrophobic properties. The self-cleaning polyester fiber for bedding filling is prepared through the following steps:

[0042] S1. Melt blending cellulose acetate butyrate and low-melting point polyester with a mass ratio of 8:1 as the cortex spinning raw material, and conventional polyester melt blending as the core spinning raw material;

[0043] S2. Putting the skin layer ...

Embodiment 2~8

[0051] Compared with Example 1, the self-cleaning polyester fiber for bedding provided in Examples 2-8 is different in that TiO 2 Particle size, skin thickness, cellulose acetate butyrate (m 1 ) and low melting point polyester (m 2 ) mass ratio and cortex spinning raw material (m 3 ) and core spinning material (m 4 ) quality ratio as shown in Table 1, others are basically the same as in Example 1, and will not be repeated here.

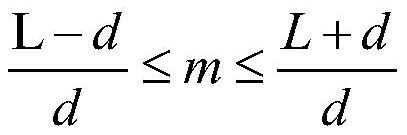

[0052] In the following examples, the loading amount of titanium dioxide nanoparticles is calculated according to the thickness of the polyester fiber skin layer and the particle size of titanium dioxide, so as to reasonably control the speed, flow rate and bombardment time of the high-speed titanium dioxide nanoparticle flow.

[0053] Preparation conditions and performance test results of Table 1 Embodiment 2~8

[0054]

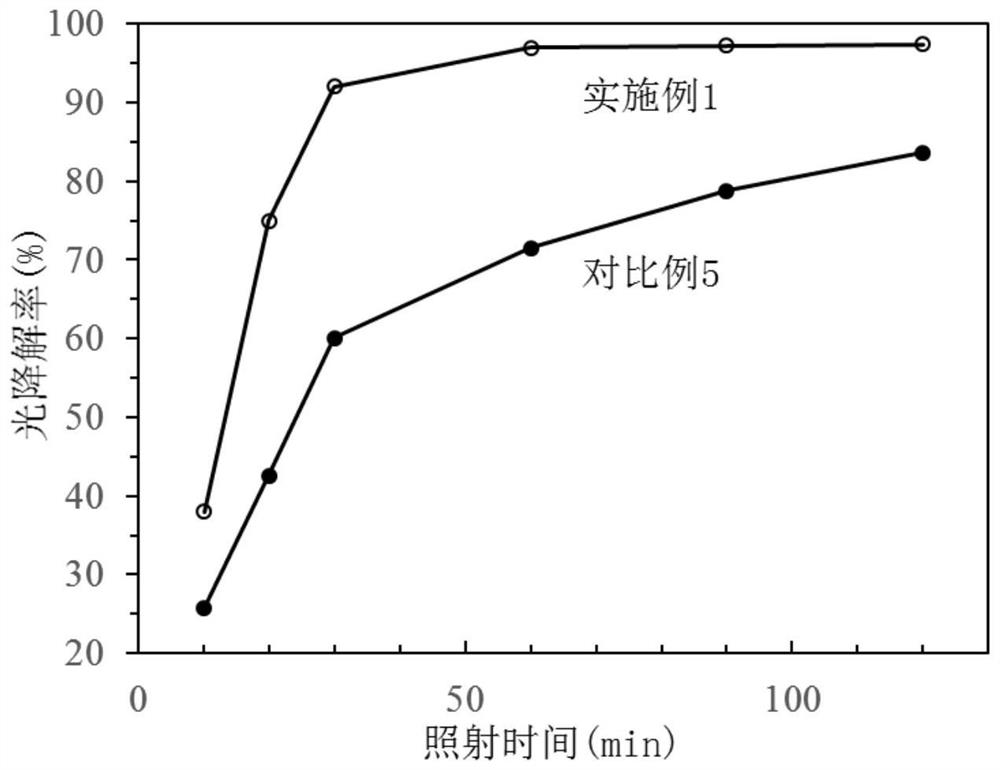

[0055] As can be seen from Table 1, with cellulose acetate butyrate (m 1 ) and low melting point polyester (m 2 ) decreas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com