Steel pipe sealing mechanism

A technology for sealing and steel pipes, which is applied in the field of steel pipe sealing mechanisms to achieve the effects of avoiding uneven extrusion, increasing applicability, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

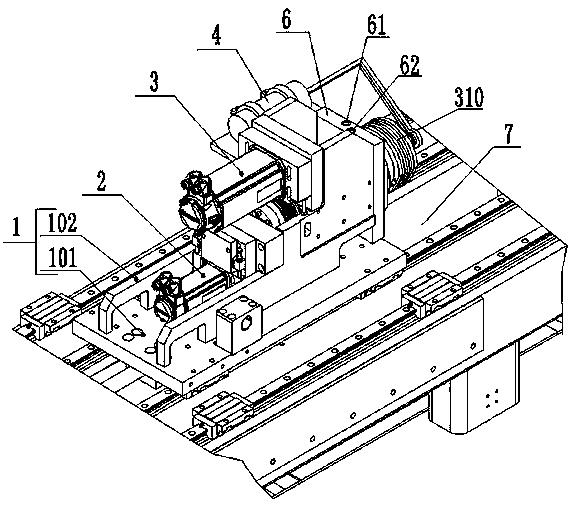

[0031] Embodiment 1 A steel pipe sealing mechanism

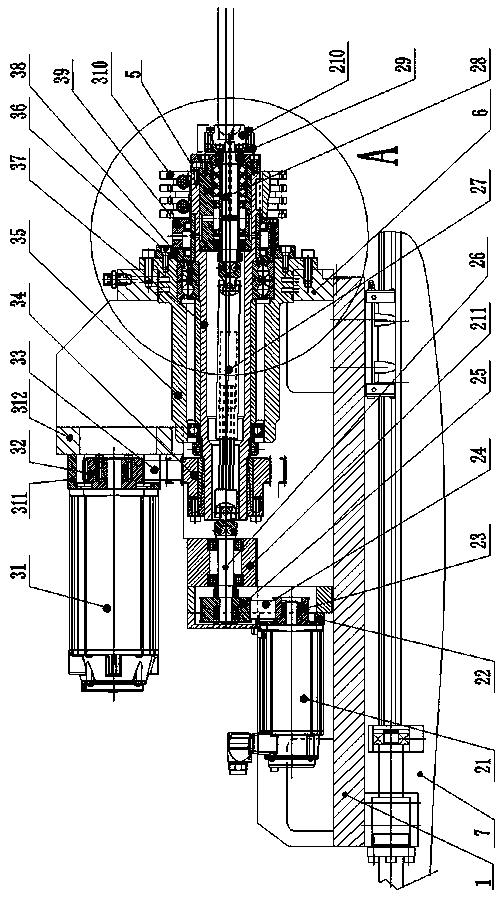

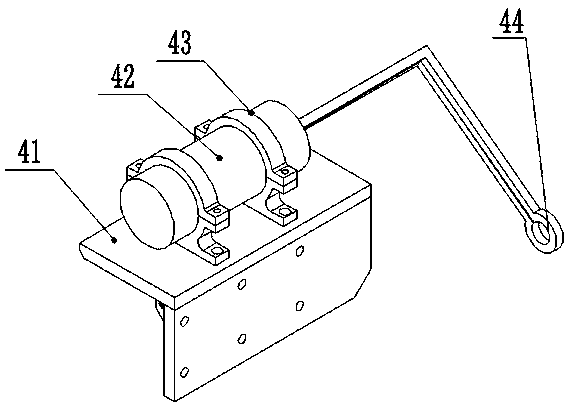

[0032] Such as Figure 1-4 As shown, the present invention provides a steel pipe sealing mechanism, including an inner main shaft assembly 2, an outer main shaft assembly 3 and a heating system 4; , the spindle support 1 includes a bottom plate 101 and a vertical support plate 102, the vertical support plate 102 is welded and fixed on the bottom plate 101; the number of the vertical support plates 102 is two, and the two vertical support plates 102 are arranged at a certain distance; The bottom plate 101 is slidably disposed on the body 7 .

[0033] The inner spindle assembly 2 includes an inner spindle 28, an inner spindle motor 21 and a sealing mold 210; the inner spindle motor 21 is fixed on the inner spindle motor mounting plate 22; the inner spindle motor mounting plate 22 is fixed on the spindle support 1 Above; the output shaft end of the inner main shaft motor 21 is provided with an inner main shaft driving pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com