Cavity part machining tooling and machining method thereof

A part processing and cavity technology, which is applied in the field of mechanical tools, can solve the problems of high processing cost and long processing time, and achieve the effects of strong practicability, improved processing efficiency and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

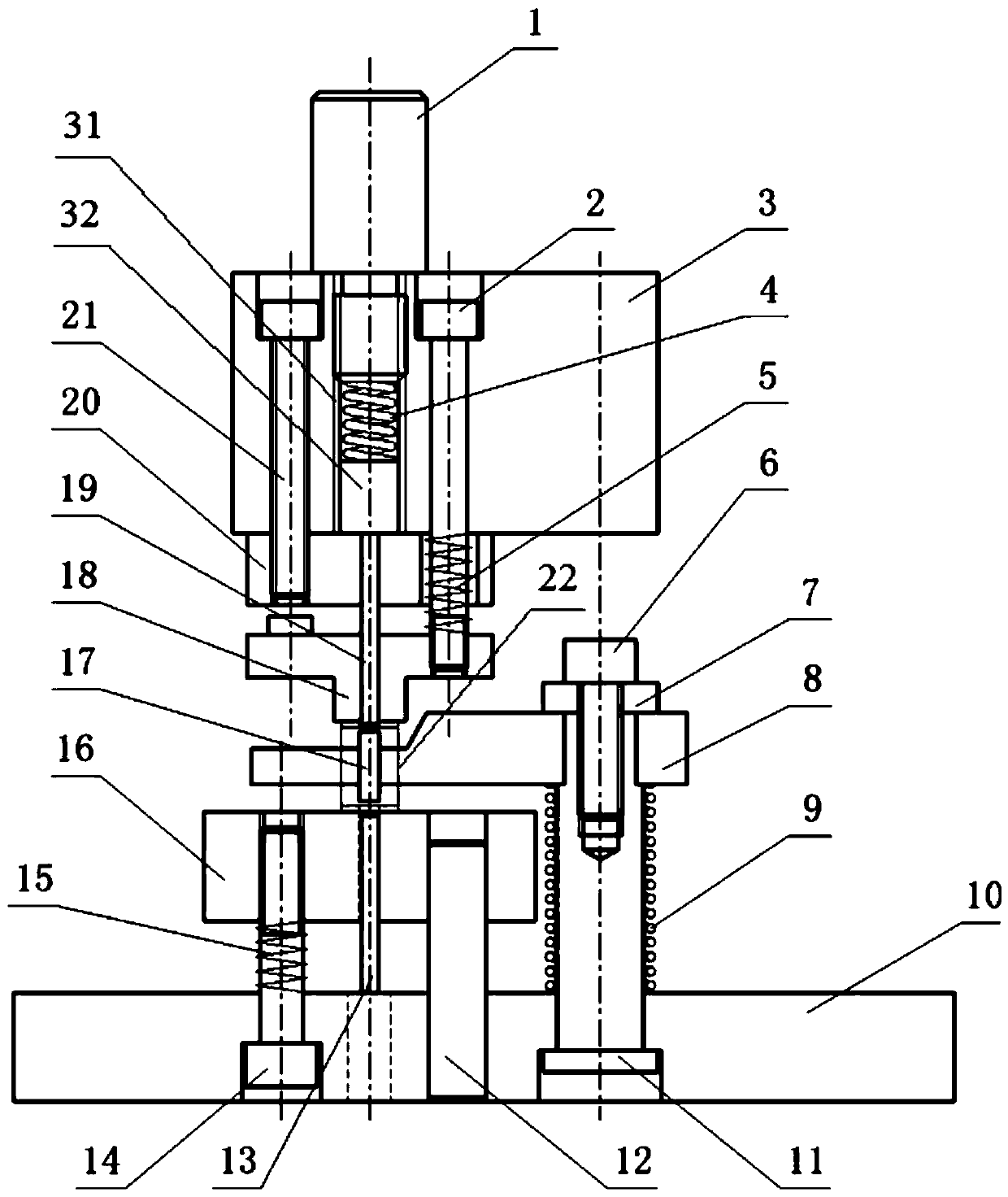

[0018] The technical problem to be solved by the present invention is: the square groove right-angle machining of cavity parts usually requires right-angle inserting, wire cutting, electric spark and other processes to realize. In slotting machining, in order to reduce the amount of product deformation, it is usually processed with smaller cutting parameters, so the processing time is longer; in wire cutting and EDM, the processing cost is higher. The technical thought that the present invention proposes with regard to this technical problem is: through the structure of the 4th spring 4, slide block 32 and the second cutter bar 19, and by the second cutter bar 19, the first cutter bar 13 and the trimming tool 17 Axes are set, both can realize the square groove chamfering processing of workpiece 22 cavity tops, also can realize the square groove chamfering processing of workpiece 22 cavity bottoms, like this, the stroke that the chamfering tool 17 and workpiece 22 move relativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com