Monitoring system and method for centralized monitoring of plate flow production line

A centralized monitoring and monitoring system technology, applied in the pretreatment of molding materials, wood processing appliances, household components, etc., can solve the problems of reducing corporate profits, long distance between equipment and equipment, occupying production workshop space, etc., to reduce operating costs. , The effect of reducing labor costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

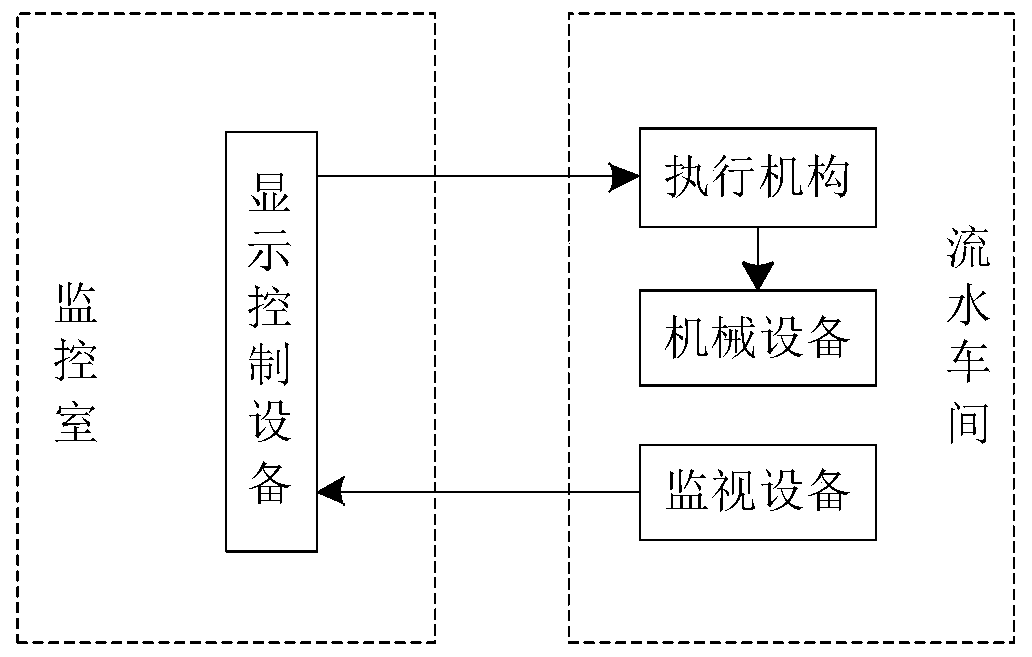

[0046] This embodiment provides a monitoring system for centralized monitoring of the plate flow production line, such as figure 1As shown, including the monitoring equipment, actuators and mechanical equipment located in the production workshop, as well as the display control equipment for centralized control located in the monitoring room;

[0047] The monitoring device is used to monitor the operation status of each process in the production workshop, collect the operation images of each process in the production workshop, and send the operation images to the display control device;

[0048] The display control device is used to display the operation image, obtain the work order of the staff, and send the work order to the execution agency;

[0049] The executive mechanism is used to control the corresponding mechanical equipment to work according to the work order.

[0050] In the traditional plate flow production line, the control system (buttons, switches) and execution...

Embodiment 2

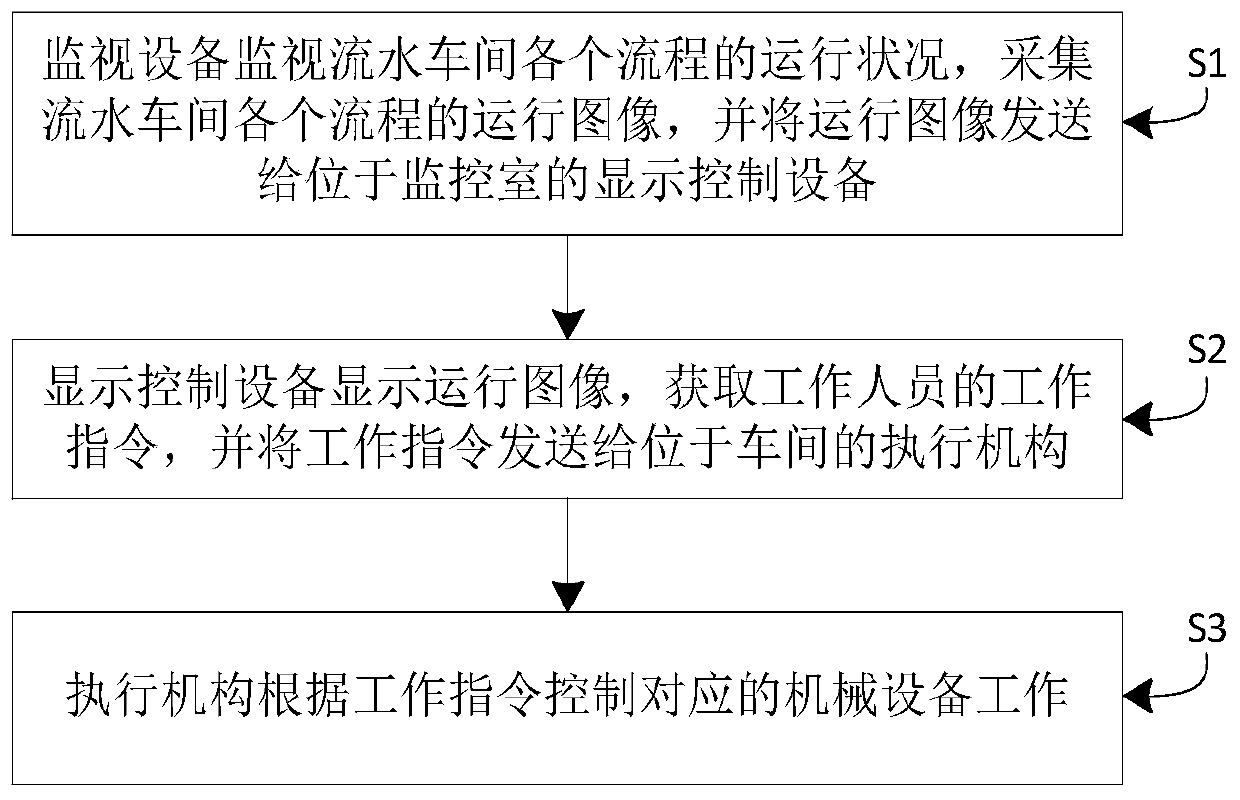

[0103] This embodiment provides a monitoring method for centralized monitoring of the sheet metal flow production line, which is applicable to the monitoring system for the centralized monitoring of the sheet metal flow production line described in Embodiment 1, such as figure 2 shown, including the following steps:

[0104] S1, the monitoring equipment monitors the operation status of each process in the production workshop, collects the operation images of each process in the production workshop, and sends the operation images to the display control equipment located in the monitoring room;

[0105] S2, the display control device displays the running image, obtains the work order of the staff, and sends the work order to the actuator located in the workshop;

[0106] S3, the actuator controls the work of the corresponding mechanical equipment according to the work instruction.

[0107] In the traditional plate flow production line, the control system (buttons, switches) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com