Online overload clearance fine adjustment device for ultra-wide PC sheet forming machine

A PC sheet and fine-tuning device technology, which is applied to flat products, household appliances, and other household appliances, can solve problems such as waste of raw materials, increased initial preparation time for molding machines, and increased manufacturing costs of ultra-wide PC sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

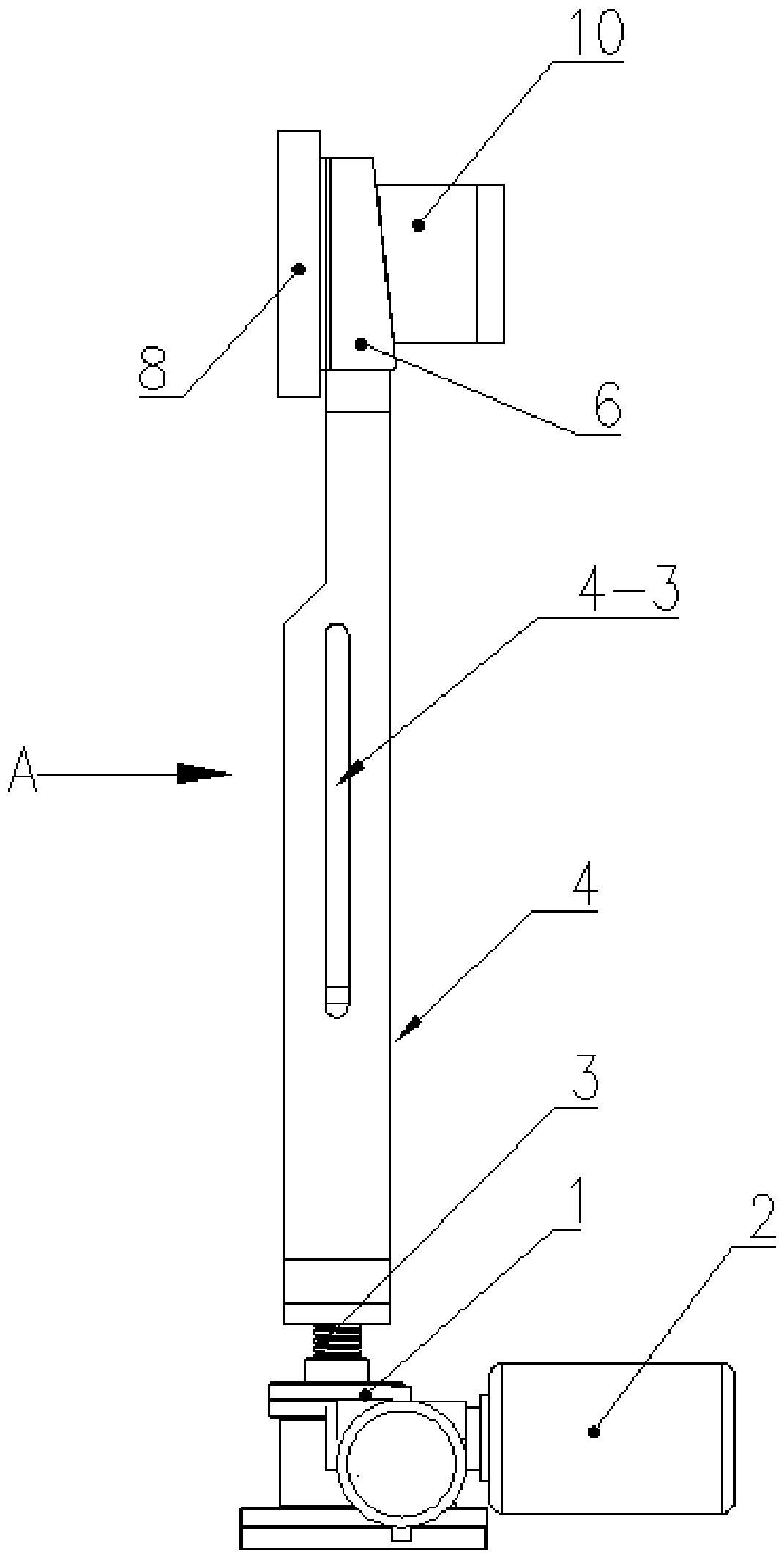

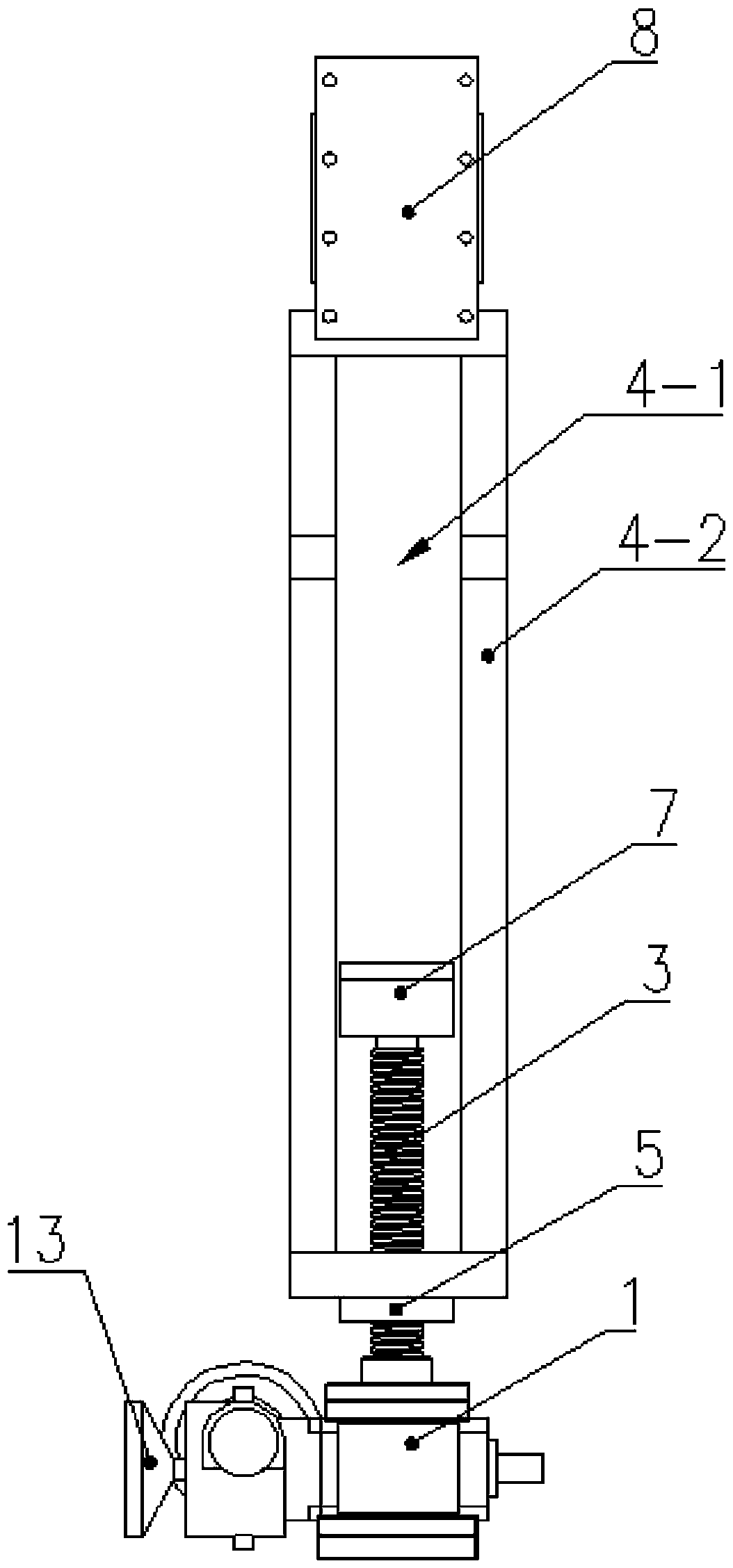

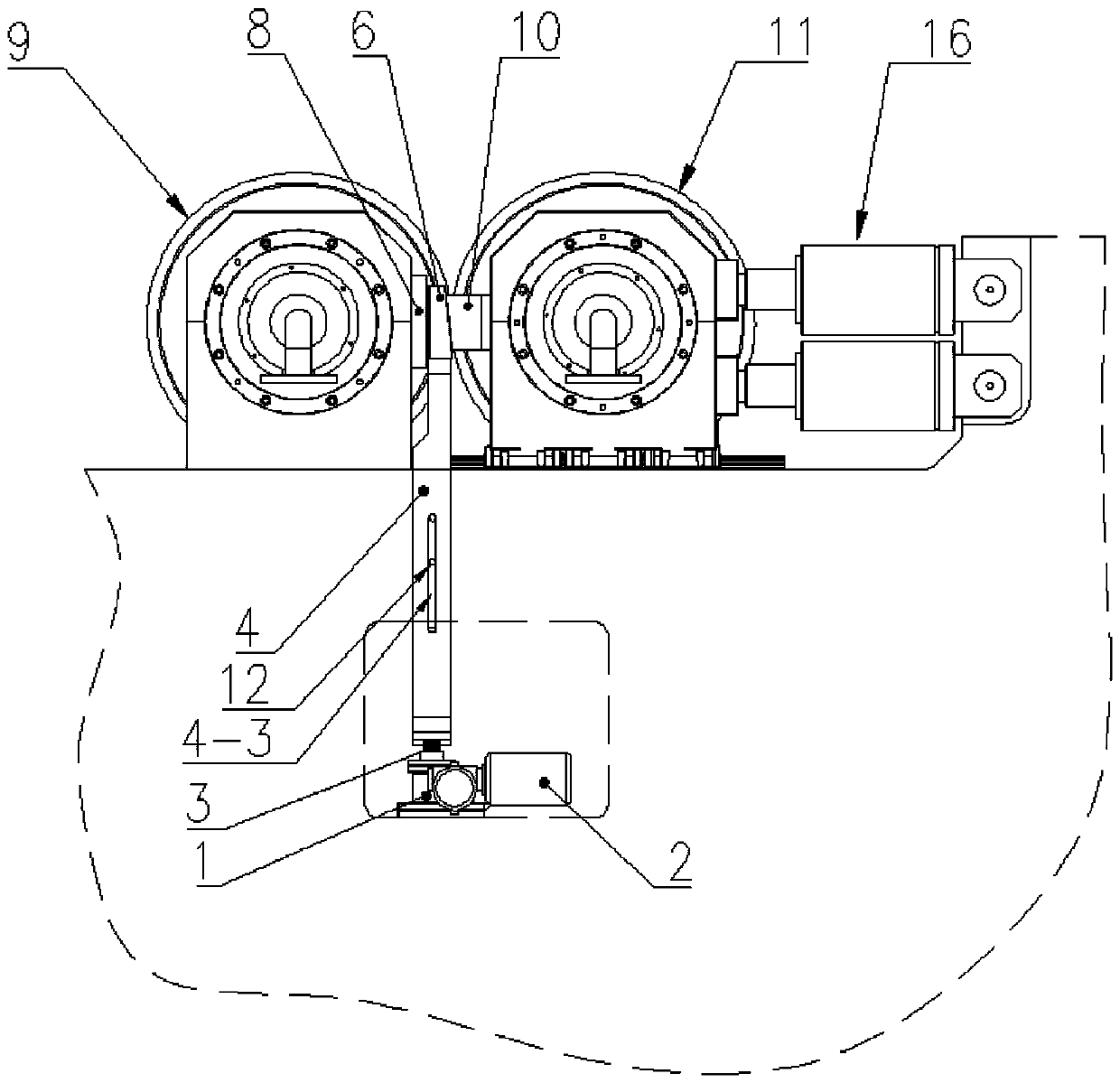

[0020] see Figure 1 to Figure 4 , an online heavy-duty gap fine-tuning device for an ultra-wide PC sheet forming machine, comprising a lifter 1 and a motor 2 . One end of the shaft of the elevator 1 is connected to the shaft of the motor 2 through a worm gear mechanism, the worm 17 of the worm gear mechanism is driven by the motor 2, and the turbine 18 of the worm gear mechanism is fixed on the shaft of the elevator 1 in the circumferential direction. 17 meshes with the turbine 18, the motor 2 drives the worm 17 to rotate, the worm 17 meshes with the turbine 18, and the turbine 18 drives the shaft of the elevator 1 to rotate; the other end is connected with a screw 3 through a reduction gear mechanism, and the driving gear 14 of the reduction gear mechanism Circumferentially fixed on the shaft of the elevator 1, the driven gear 15 of the reduction gear mechanism is circumferentially fixed on the screw 3, the diameter of the driving gear 14 is smaller than the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com