Composite forming method of multifunctional integrated composite material

A composite material and composite forming technology, applied in additive processing, additive manufacturing, 3D object support structure, etc., can solve the problems of complex integral forming, shorten the manufacturing cycle, ensure the integrity and comprehensive performance, and have strong designability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

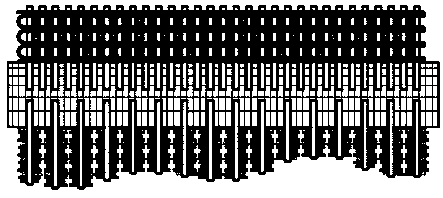

[0032] like Figure 4 As shown in the schematic diagram of the composite material curved surface member, using a composite forming method of a multifunctional integrated composite material of the present invention, the weaving forming steps are as follows:

[0033] ① Use CAD and other software to establish the 3D CAD model of the surface component, and divide the 3D CAD model into functional area 1, functional area 2 and transition area;

[0034] ②Functional area 1 is the basic frame and main part of the component, which is formed by the flexible guiding three-dimensional weaving forming process;

[0035] ③Functional area 2 is mainly a few reinforcing ribs on the outer layer of the component, using continuous fiber 3D printing technology;

[0036] ④ According to the performance requirements of functional area 1 and functional area 2, establish the 3D CAD model of the transition area between functional area 1 and functional area 2;

[0037] ⑤Using the flexible-guided three-di...

Embodiment 2

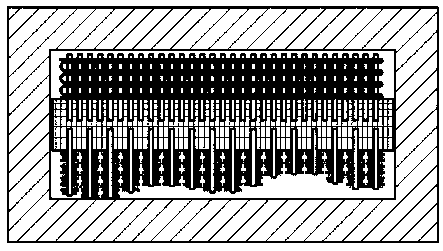

[0041] like Figure 5 As shown in the schematic diagram of the multi-functional integrated composite material component of the complex structure, using a composite forming method of the multi-functional integrated composite material of the present invention, the weaving and forming steps are as follows:

[0042] ① Establishing a three-dimensional CAD model of the complex structural composite material component, and partitioning the three-dimensional CAD model to obtain functional area 1, functional area 2, functional area 3, transition area 1, and transition area 2;

[0043] ②Using 3D printing technology to manufacture transition zone 1 and transition zone 2 of short fiber reinforced composite materials, the density of short fibers in transition zone 1 is distributed in a gradient along the radial direction, and the short fibers in transition zone 2 are evenly distributed;

[0044] ③ Arrange the guide arrays of functional area 1 and functional area 2 through the guide template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com