Thermal management method and system for electric vehicle and vehicle

An electric vehicle and thermal management technology, applied in electric vehicles, vehicle energy storage, vehicle components, etc., can solve the problem of considering energy consumption optimization, failing to meet the heating or cooling needs of the power battery and passenger compartment, and unable to adjust thermal management strategies, etc. problem to achieve the effect of meeting heating or cooling needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

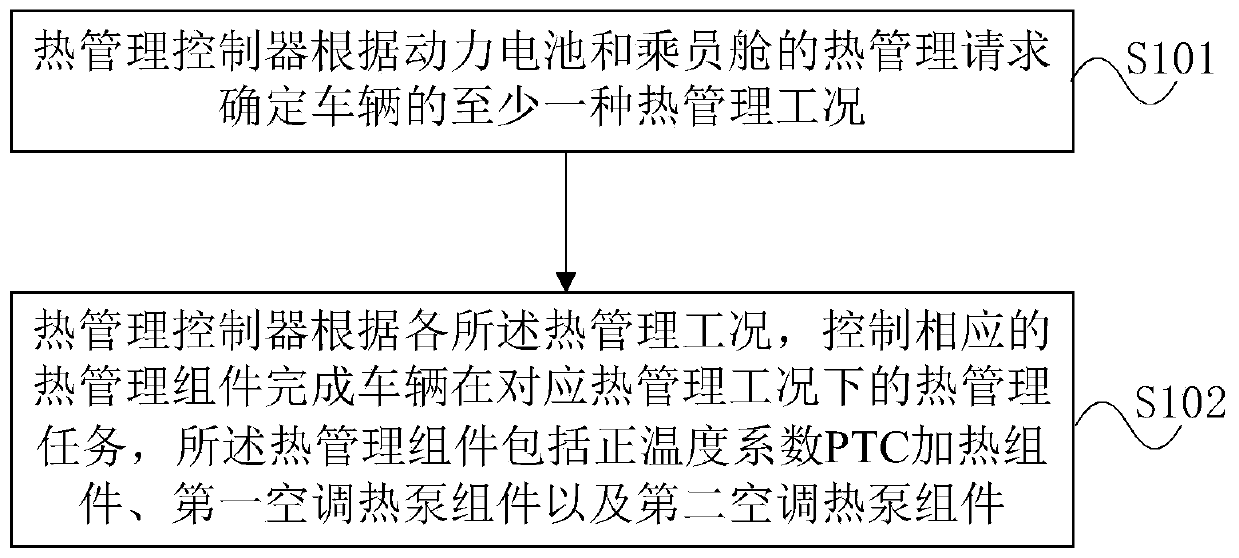

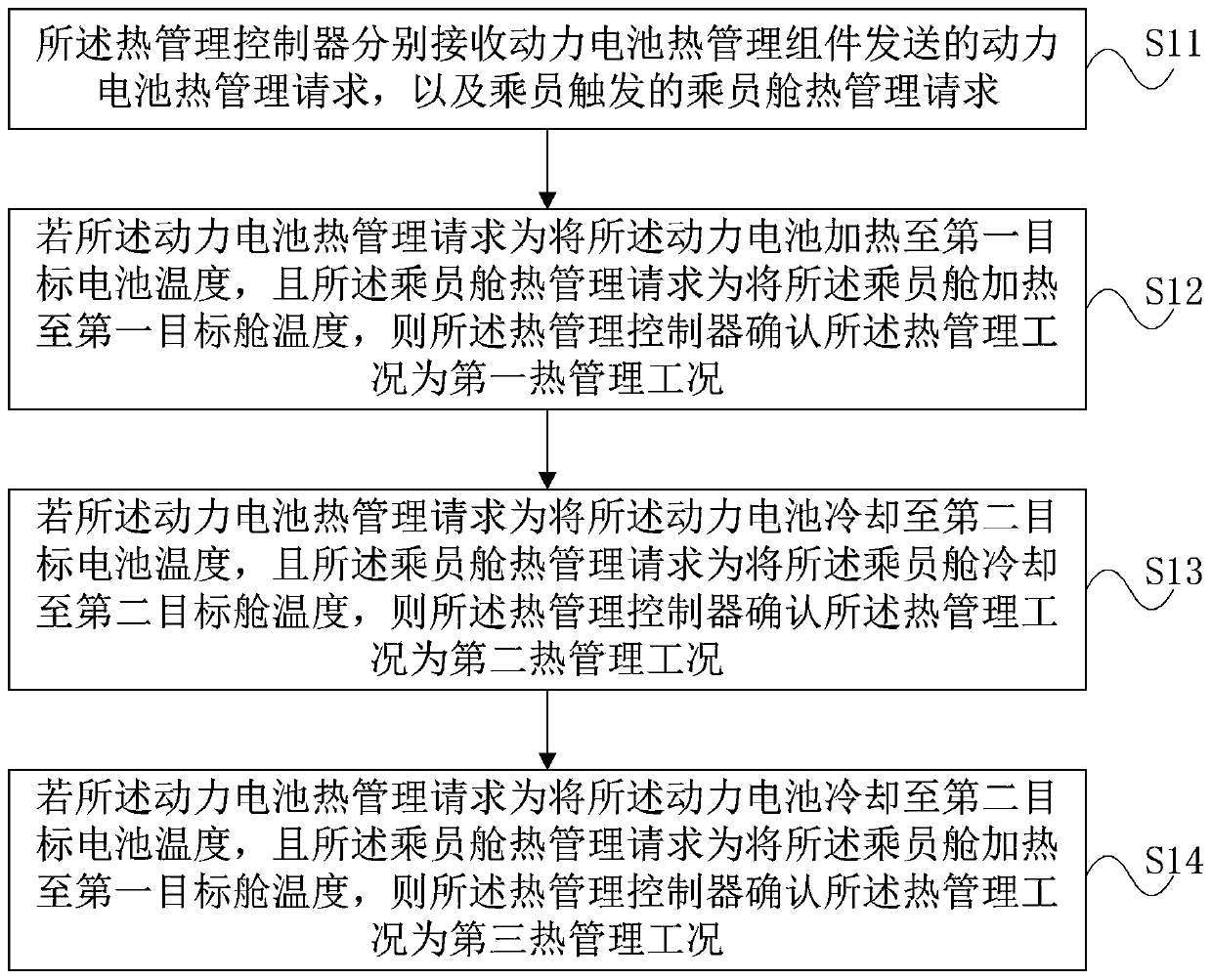

[0029] figure 1 It is a schematic flow chart of a thermal management method for an electric vehicle provided in Embodiment 1 of the present invention. This embodiment is applicable to heating or In case of cooling, the method may be executed by the thermal management controller in the embodiment of the present invention.

[0030] It is understandable that the power battery needs to be cooled accurately during the daily discharge and charging process to prevent the temperature from being too high; at the same time, in the colder environment in the northern region, there are still working conditions where the power battery needs to be heated. In addition, the heating temperature and heating rate should be controlled more precisely to prevent the life of the battery from attenuating due to excessive temperature rise impact. The current battery heating method mainly uses high-power PTC to heat the coolant and perform direct heat exchange with the power battery. Air-conditioning h...

Embodiment 2

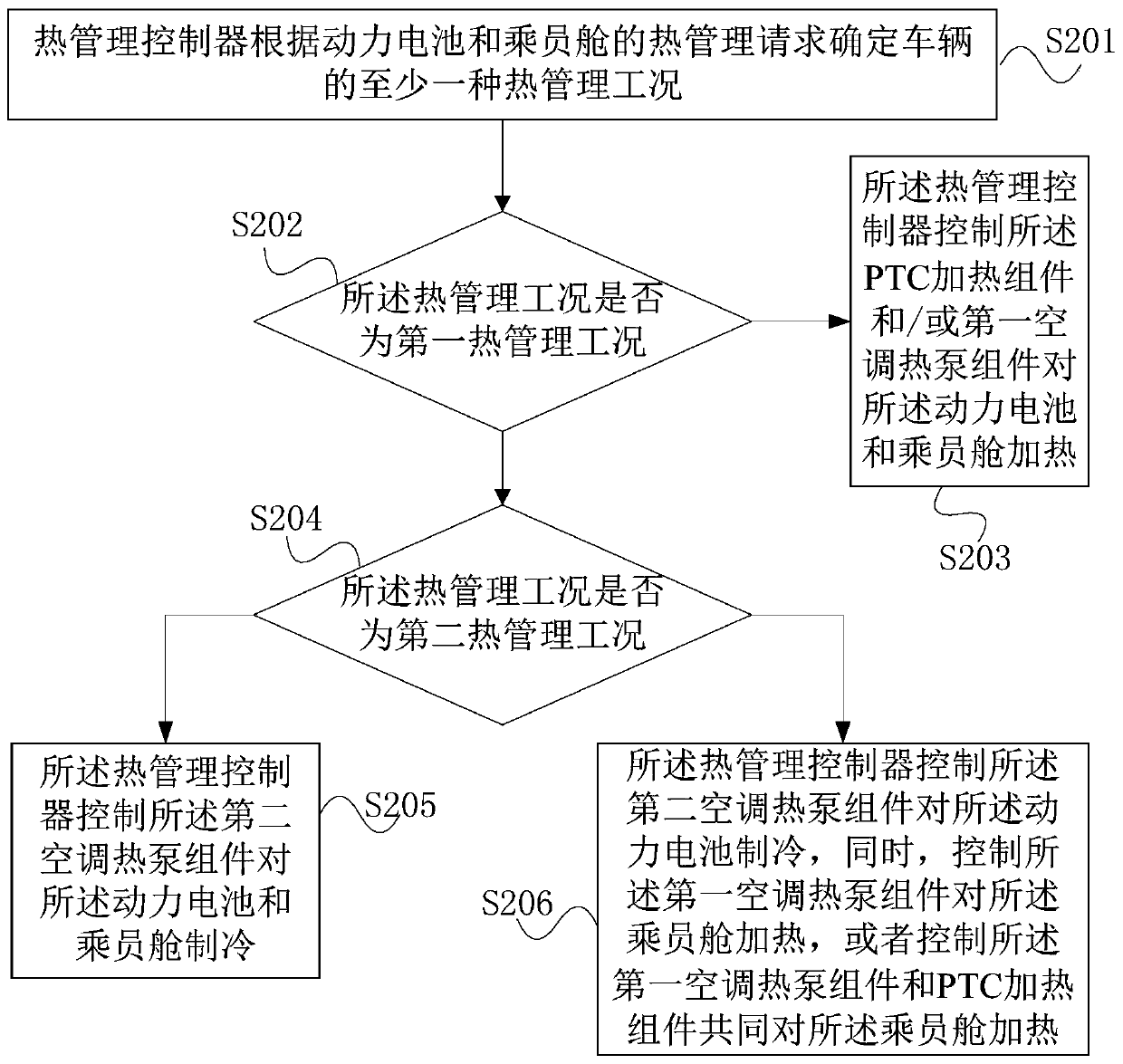

[0063] image 3 It is a schematic flowchart of a thermal management method for an electric vehicle provided in Embodiment 2 of the present invention. This embodiment is further optimized on the basis of Embodiment 1. In this embodiment, the thermal management controller controls the corresponding thermal management components to complete the thermal management tasks of the vehicle under the corresponding thermal management conditions according to each of the thermal management conditions, which is embodied as: if the thermal management conditions is the first thermal management condition, the thermal management controller controls the PTC heating component and / or the first air-conditioning heat pump component to heat the power battery and the passenger compartment; if the thermal management condition is the second thermal management working condition, the thermal management controller controls the second air-conditioning heat pump assembly to cool the power battery and the pas...

Embodiment 3

[0138] Figure 7 It is a schematic structural diagram of an electric vehicle thermal management system provided by Embodiment 3 of the present invention. This embodiment is applicable to adopting different thermal management strategies for heating or In case of cooling, the system includes: thermal management controller 301, power battery thermal management component 302, first air conditioner heat pump component 303, second air conditioner heat pump component 304, PTC heating component 305, power motor component 306 and power motor cooling component 307 ,

[0139] Wherein, the thermal management controller 301 is respectively connected with the power battery thermal management component 302 , the first air conditioner heat pump component 303 , the second air conditioner heat pump component 304 , the PTC heating component 305 , the power motor component 306 and the power motor cooling component 307 .

[0140] The thermal management controller 301 is used to determine at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com