Cosmetic packaging dropper bottle safety for children

A child safety and cosmetic technology, applied in the directions of packaging, transportation packaging, transportation and packaging, can solve the problems of leakage of the contents of the bottle, loosening of the bottle cap, pollution of the environment, etc., to achieve easy operation, avoid loosening, safety Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

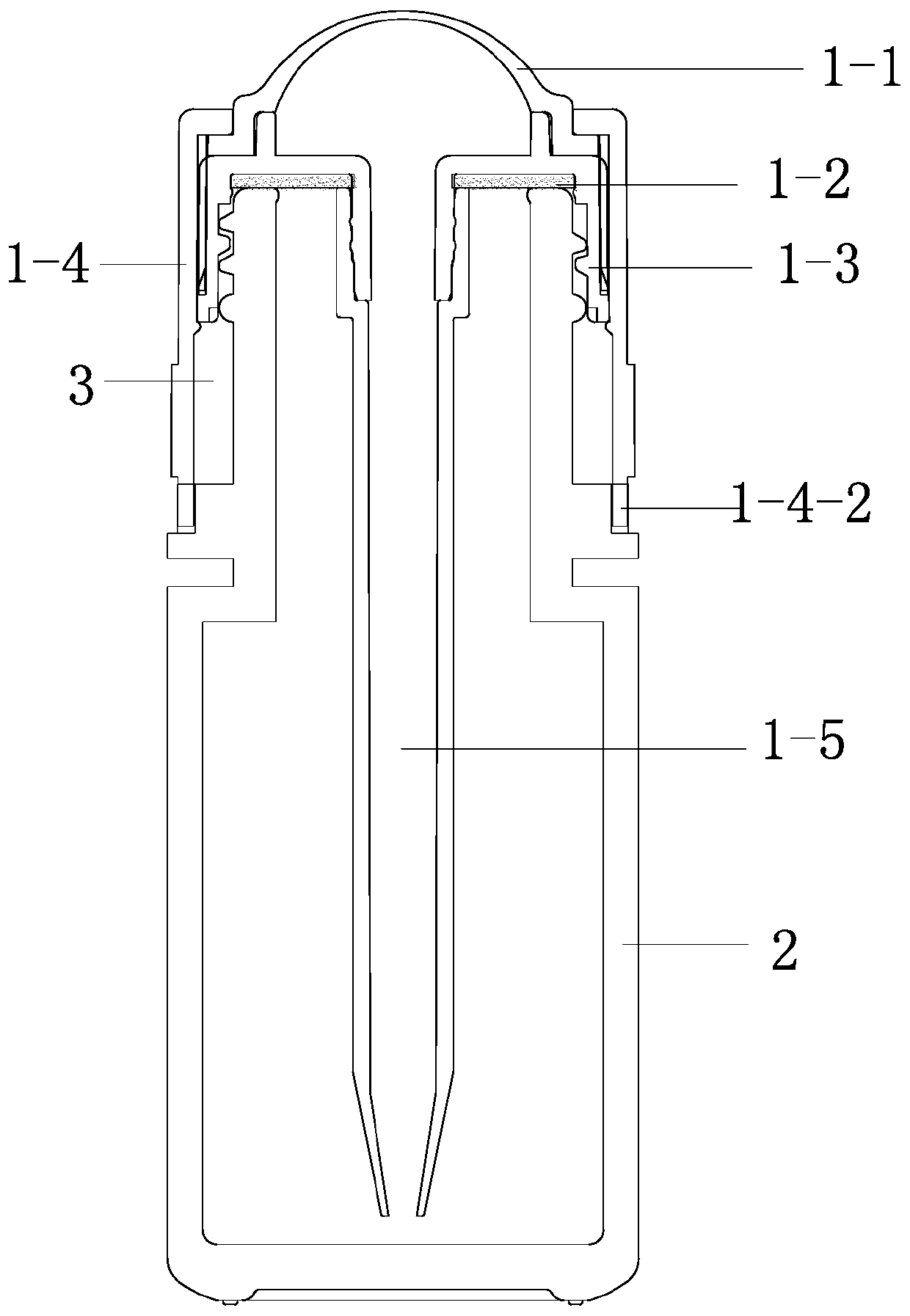

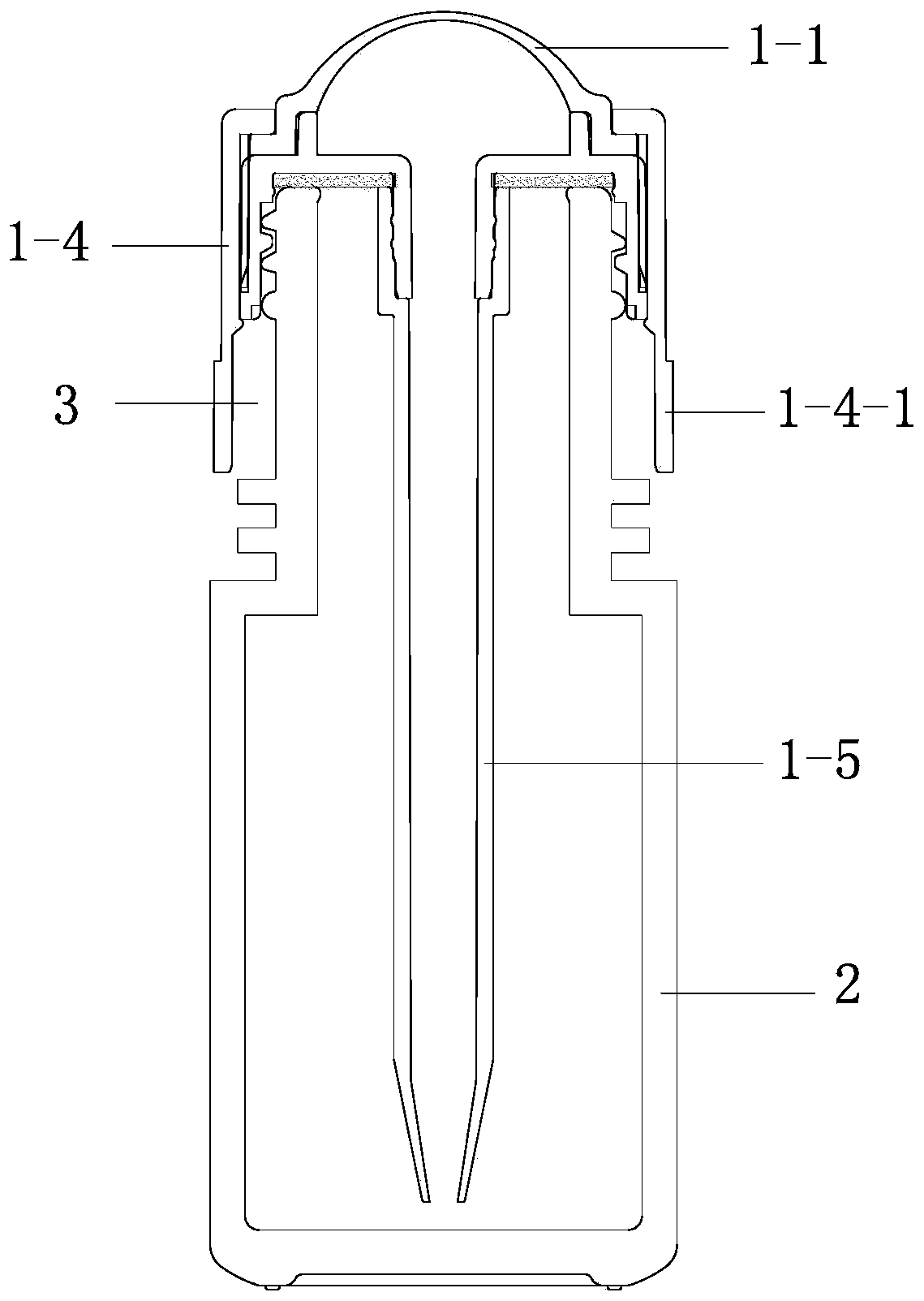

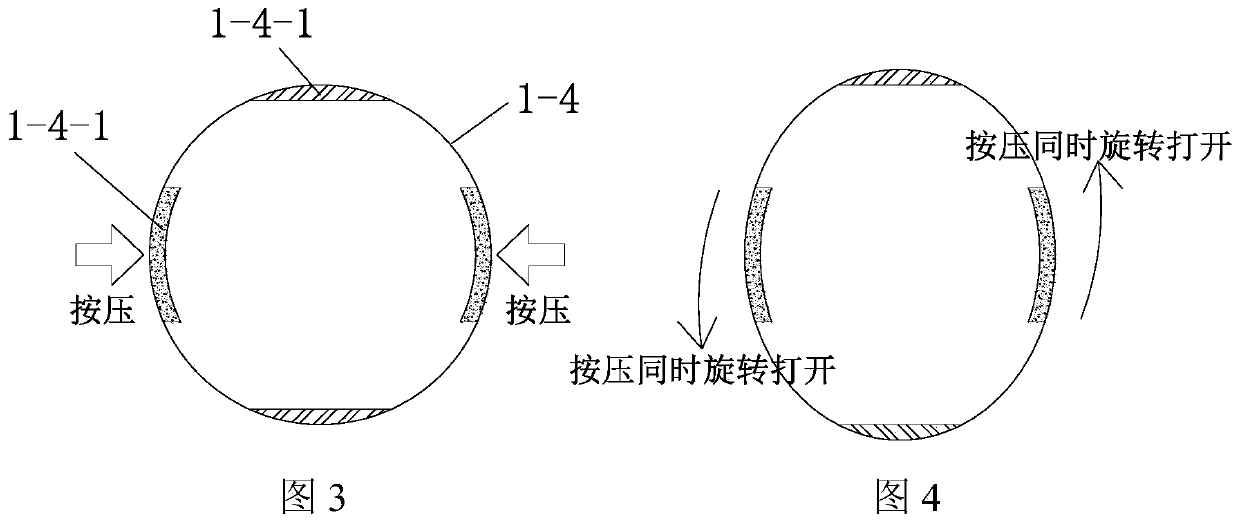

[0014] see Figure 1 ~ Figure 4 , a child-safe dropper bottle for cosmetic packaging, comprising a dropper dispenser and a bottle body 2, the dropper dispenser includes a threaded sleeve 1-3 that is sealingly connected to the upper part of the bottle neck, and the threaded sleeve 1-3 3 is fixed with a button 1-1 and a dropper 1-5 that are hermetically connected to it, and the button 1-1 communicates with the dropper 1-5, and a jacket 1-4 is set on the screw sleeve 1-3 , the screw sleeve 1-3 is clamped on the upper part of the outer jacket 1-4, a gap 3 is provided between the lower part of the outer jacket 1-4 and the bottleneck, and the lower part of the outer jacket 1-4 corresponds to the gap A pressing portion 1-4-1 is respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com