Solar glass tube impregnation and baking production line

A technology for solar glass and production lines, applied in conveyor objects, coatings, furnaces, etc., can solve the problems of rational utilization of unfavorable space, low production efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

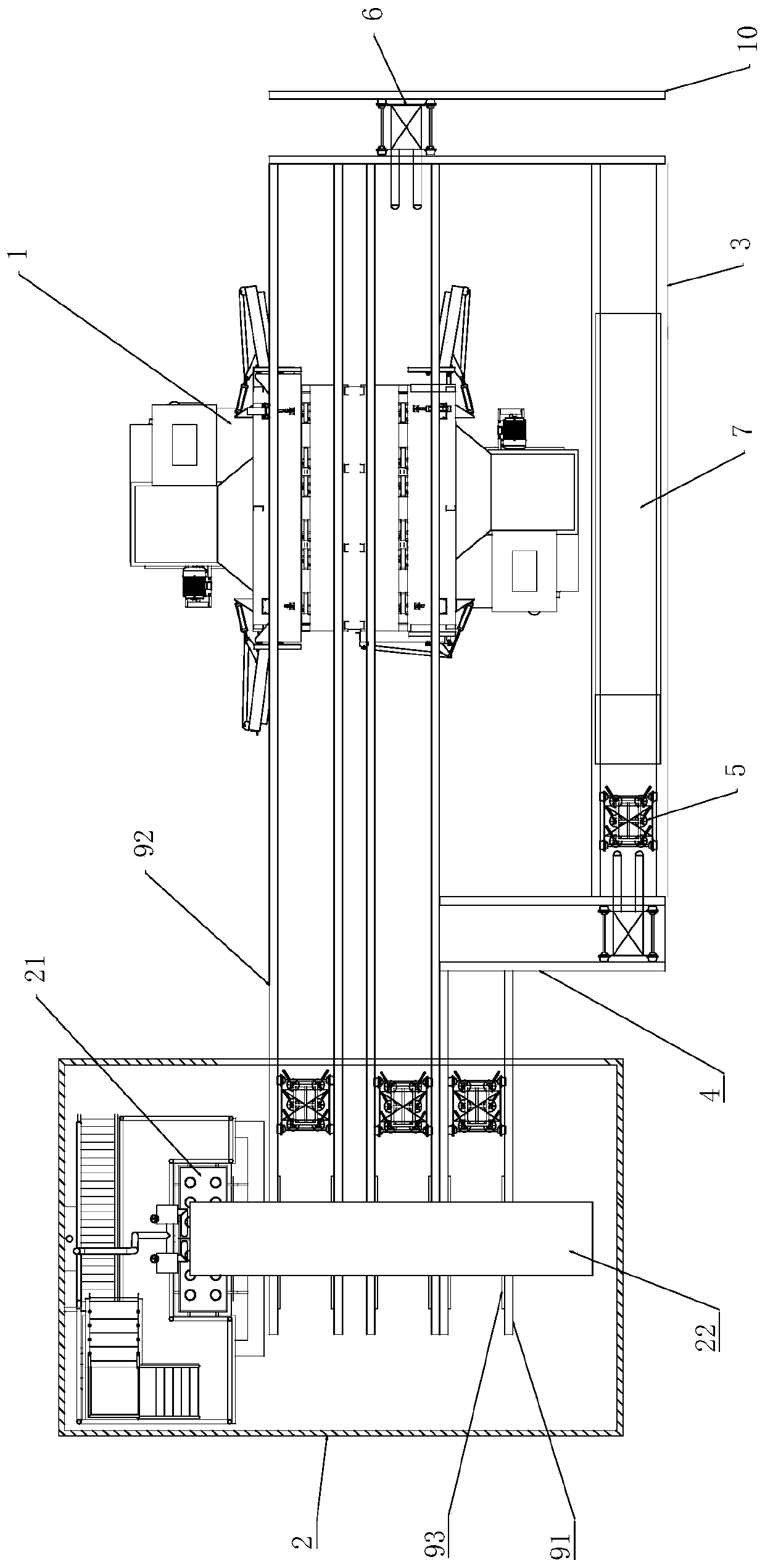

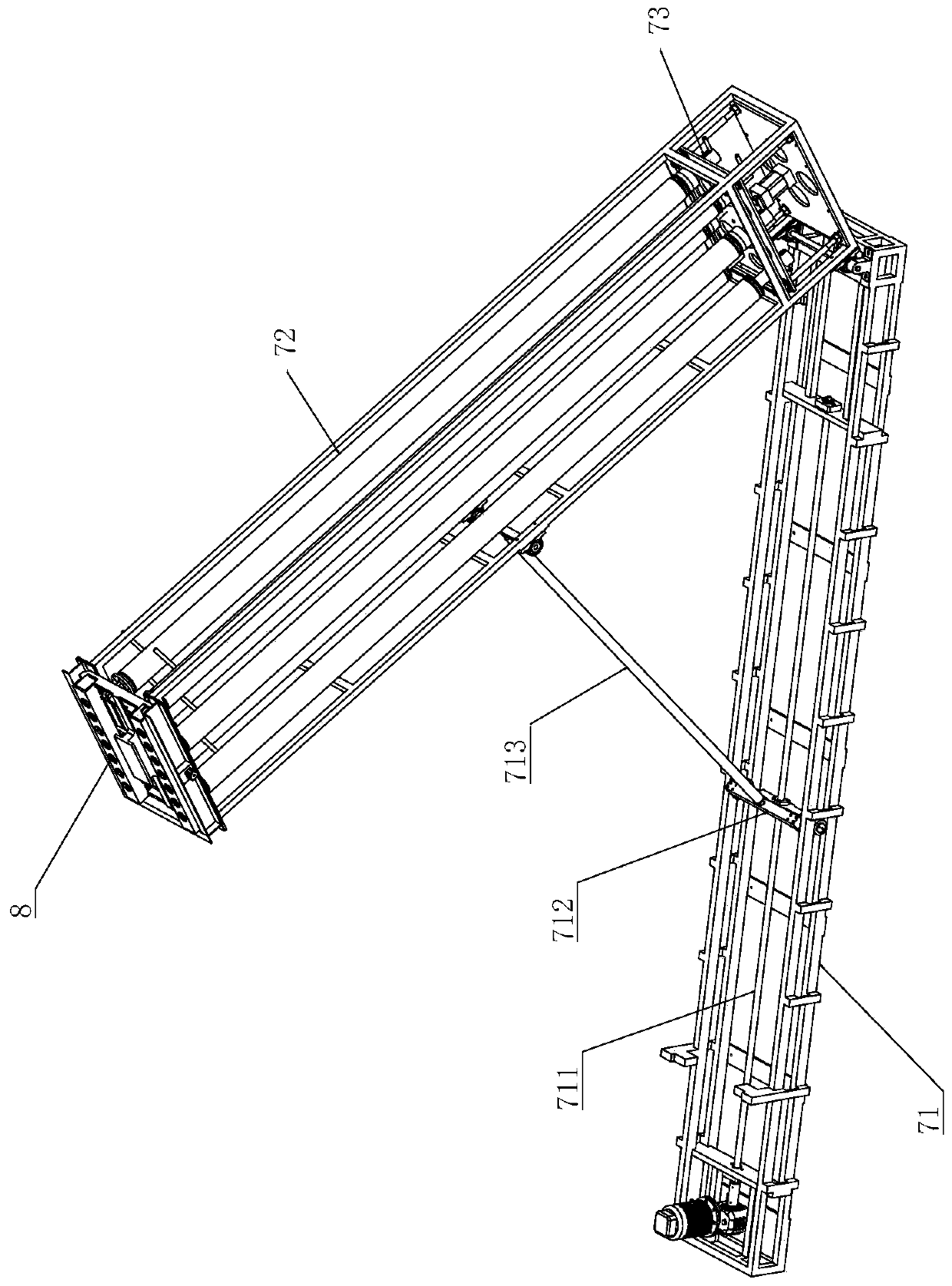

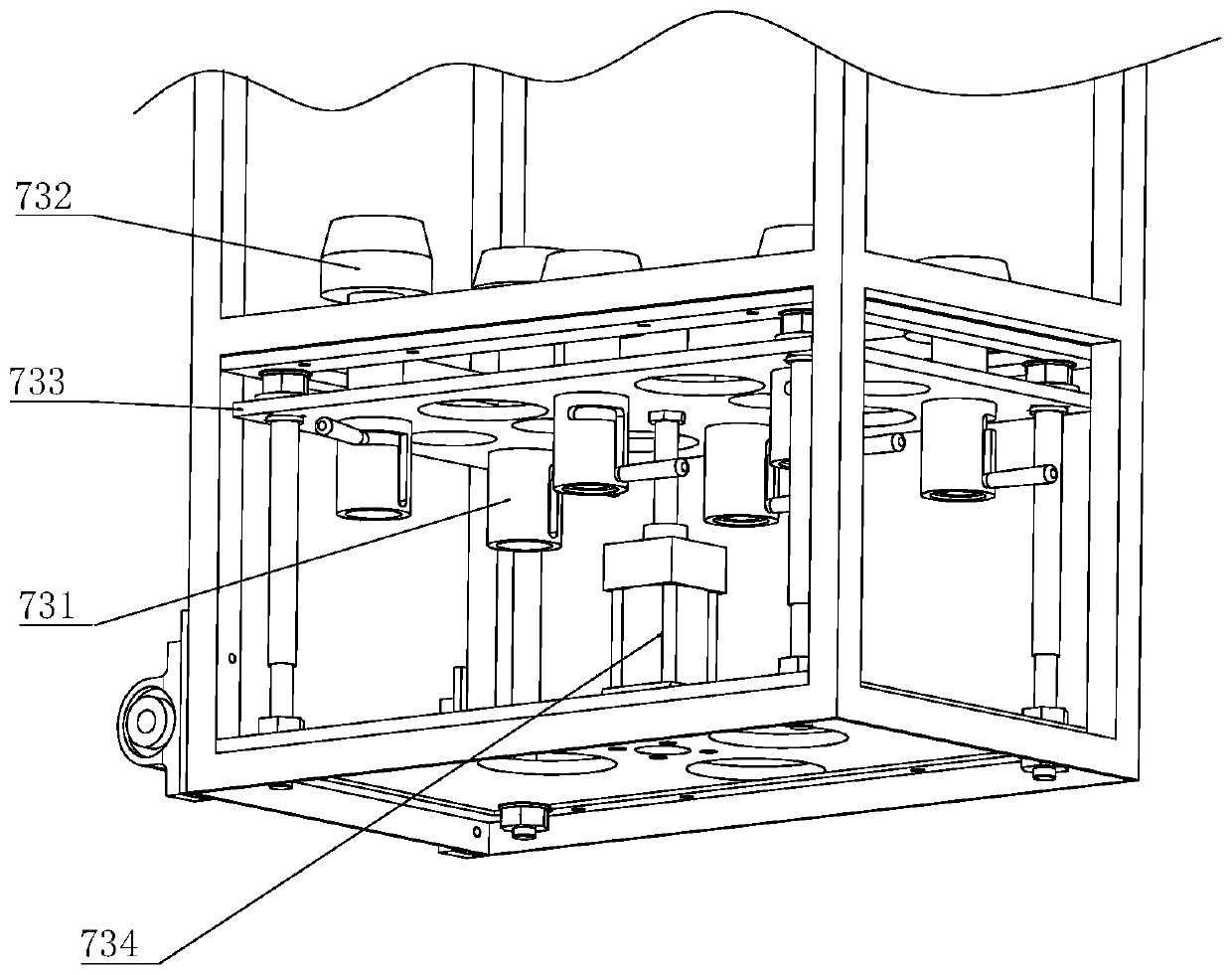

[0028] refer to figure 1 and figure 2 , the embodiment of the present invention provides a solar glass tube dipping and baking production line, including an oven 1, a dipping chamber 2, a feeding track 3, an indexing track 4, a transporting trolley 5, an indexing trolley 6, Overturning device 7, suspension jig 8, the first feeding rail 91 that is used to transport the pipe fittings to the dipping chamber 2, the second feeding rail 92 that is used to transport the pipe fittings from the dipping chamber 2 to the oven 1; The overturning device 7 is arranged below the feeding track 3, and includes a base 71, a rotating frame 72 whose lower end is rotatably connected to the base 71, and a pushing mechanism that drives the rotating frame 72 to rotate. The tool 8 can be slidably connected to the upper end of the rotating frame 72, the lower end of the hanging fixture 8 is connected with a suspension part 81 for hanging a fixed pipe, and the lower end of the rotating frame 72 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com