Wire coil transfer device

A technology of transfer device and wire reel, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of inconvenient production and processing, heavy workload, cumbersome work content, etc., to improve production and processing efficiency, The effect of improving transfer efficiency and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: As described above in this part, details are not repeated here.

Embodiment 2

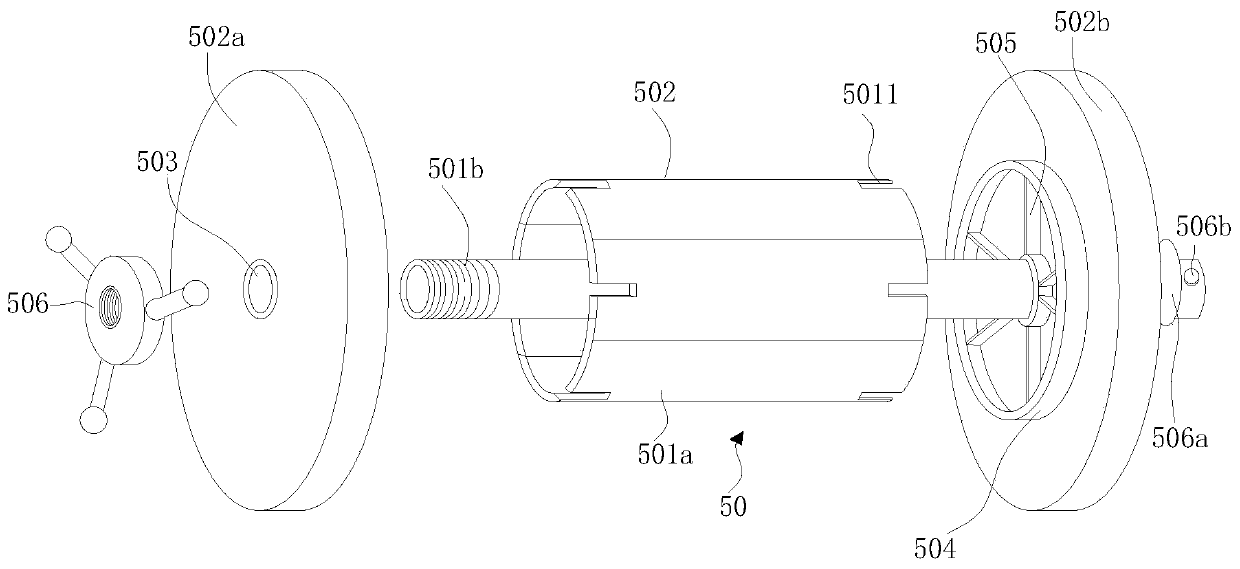

[0055] Embodiment 2: as Image 6 As shown: the winding reel 50 includes a first end plate 502a, a second end plate 502b, and a winding roller 502; the inner shaft centers of the first end plate 502a and the second end plate 502b are provided with limiting grooves 504, The axes of the first end plate 502a and the second end plate 502b are provided with a through hole 503 whose inner diameter is smaller than the inner diameter of the limiting groove 504;

[0056] Such as Image 6 , the inner side of the first end plate 502a is fixedly provided with two shaping pins 6h, and the shaping pins 6h are located inside the limiting groove 504 and distributed around the through hole 503;

[0057] Two insertion holes 6j are opened on the outer peripheral surface of the second end plate 502b, and the insertion holes 6j are holes penetrating through the side wall of the limiting groove 504;

[0058] Such as Figure 6-Figure 9 As shown, the winding roller 502 is composed of two semicircul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com