Air layer fabric, air layer jacquard fabric and weaving method thereof

A technology of air layer and fabric, which is applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of lack of innovation and achieve the effect of increasing richness, vivid patterns and novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

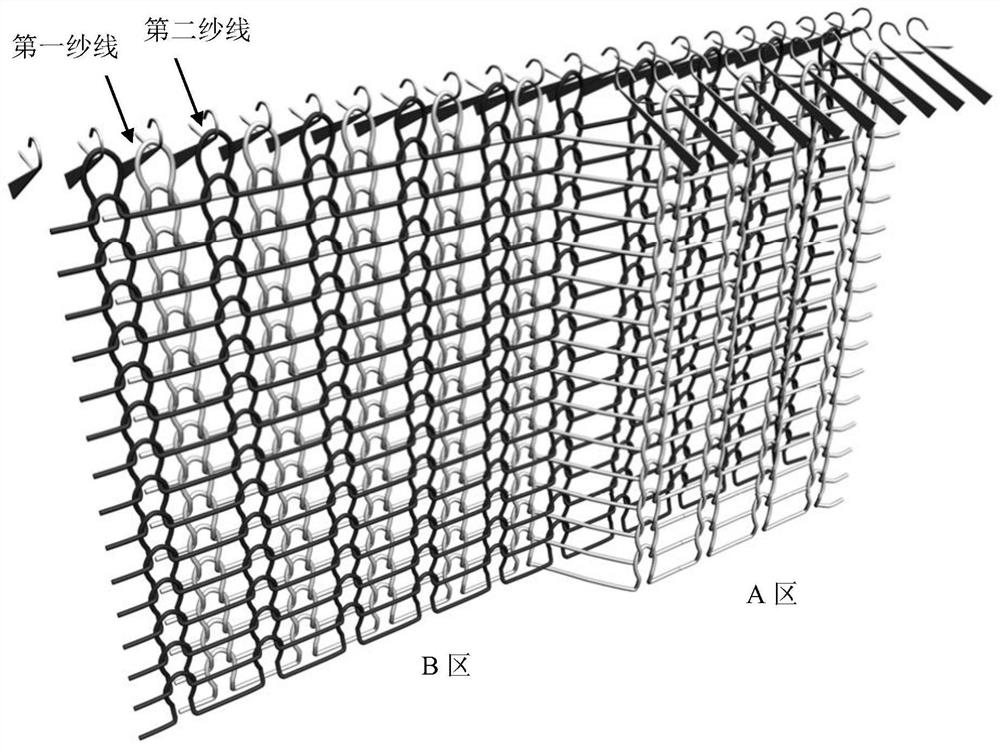

[0067] This embodiment is a weaving method of an air layer jacquard fabric, the jacquard style of the finished product is style 1, and the steps are as follows:

[0068] 1. Make computerized flat knitting machine data in the plate making system, import the required pattern, and the pattern includes A color area and B color area;

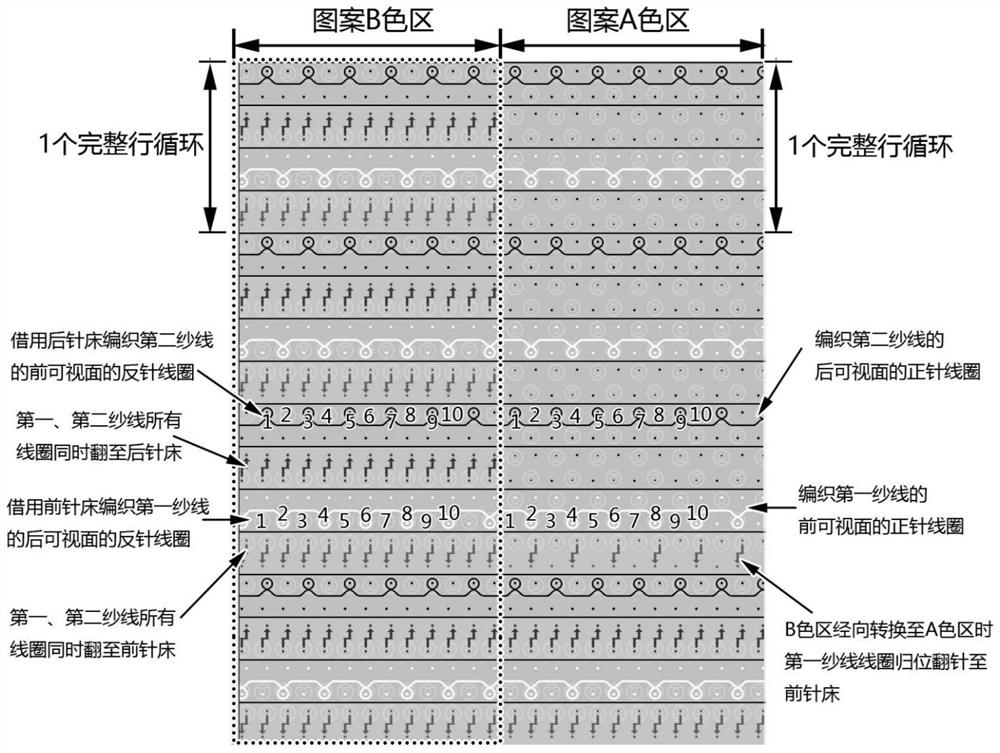

[0069] 2. The A and B color areas adopt the jacquard pattern of the above-mentioned style 1. The front and rear visible surfaces of the A color area are all positive stitches, and the front and rear visible surfaces of the B color area are all reverse stitches. The color area adopts figure 1 with 2 The transfer and 1X1 offset empty needle knitting methods in the knitting process shown are circular filling;

[0070] 3. Both the first yarn and the second yarn are made of 2 / 30 100% wool 3 yarns; the first yarn is white, and the second yarn is black;

[0071] 4. Import the data into the computerized flat knitting machine for weaving, and obtain the air...

Embodiment 2

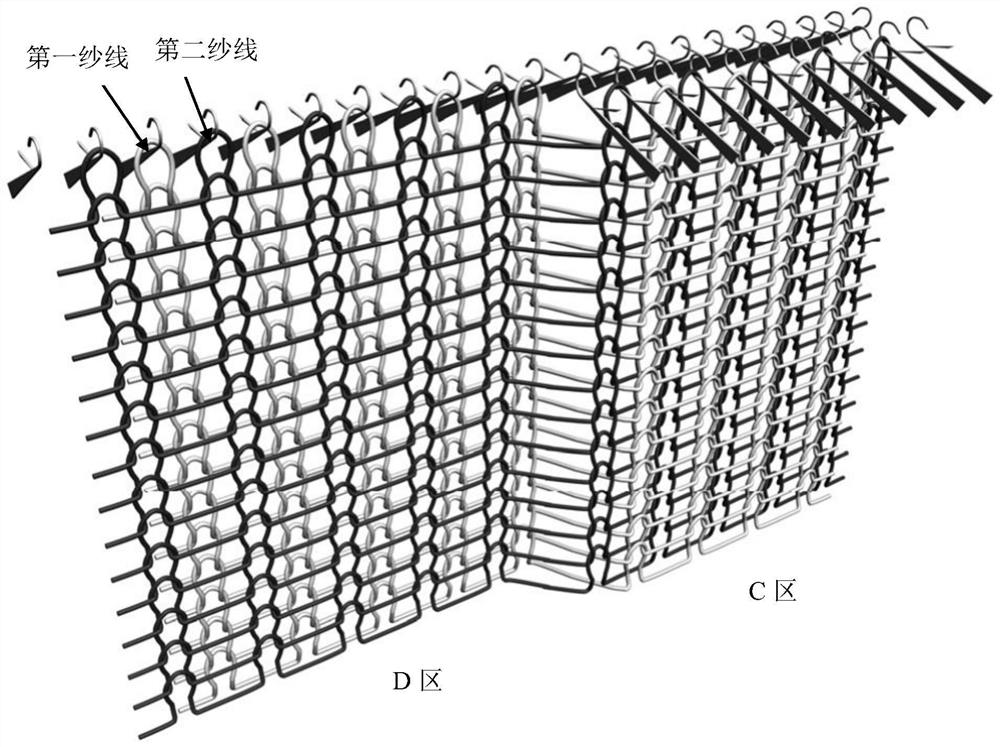

[0073] This embodiment is a weaving method of an air layer jacquard fabric, the jacquard style of the finished product is style 2, and the steps are as follows:

[0074] 1. Make computerized flat knitting machine data in the plate making system, import the required pattern, and the pattern includes C color area and D color area;

[0075] 2. The jacquard pattern of style 2 is used in the C and D color areas, and the front and rear visible surfaces are all anti-stitch stitches, and the color areas adopt image 3 with 4 The transfer and 1X1 offset empty needle knitting method in the knitting process shown is circular filling;

[0076] 3. Both the first yarn and the second yarn are made of 2 / 30 100% wool 3 yarns; the first yarn is white, and the second yarn is black;

[0077] 4. Import the data into the computerized flat knitting machine for weaving, and obtain the finished air layer jacquard fabric with reverse stitches. Finished products such as Figure 7 with 8 As shown, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com