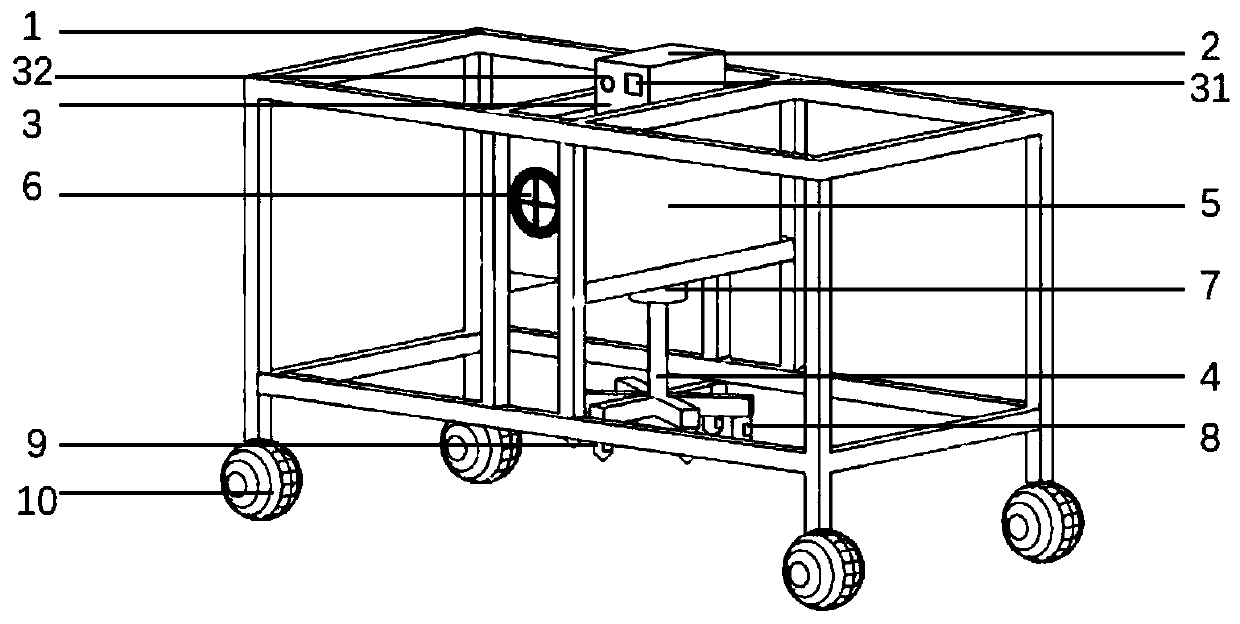

Pitch mixed material compaction shear characteristic detection device in construction compaction process

A technology of asphalt mixture and detection device, which is applied in the direction of measuring device, using stable shear force to test material strength, flow characteristics, etc., can solve problems such as insufficient stability and high quality hidden dangers, and achieve good compaction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

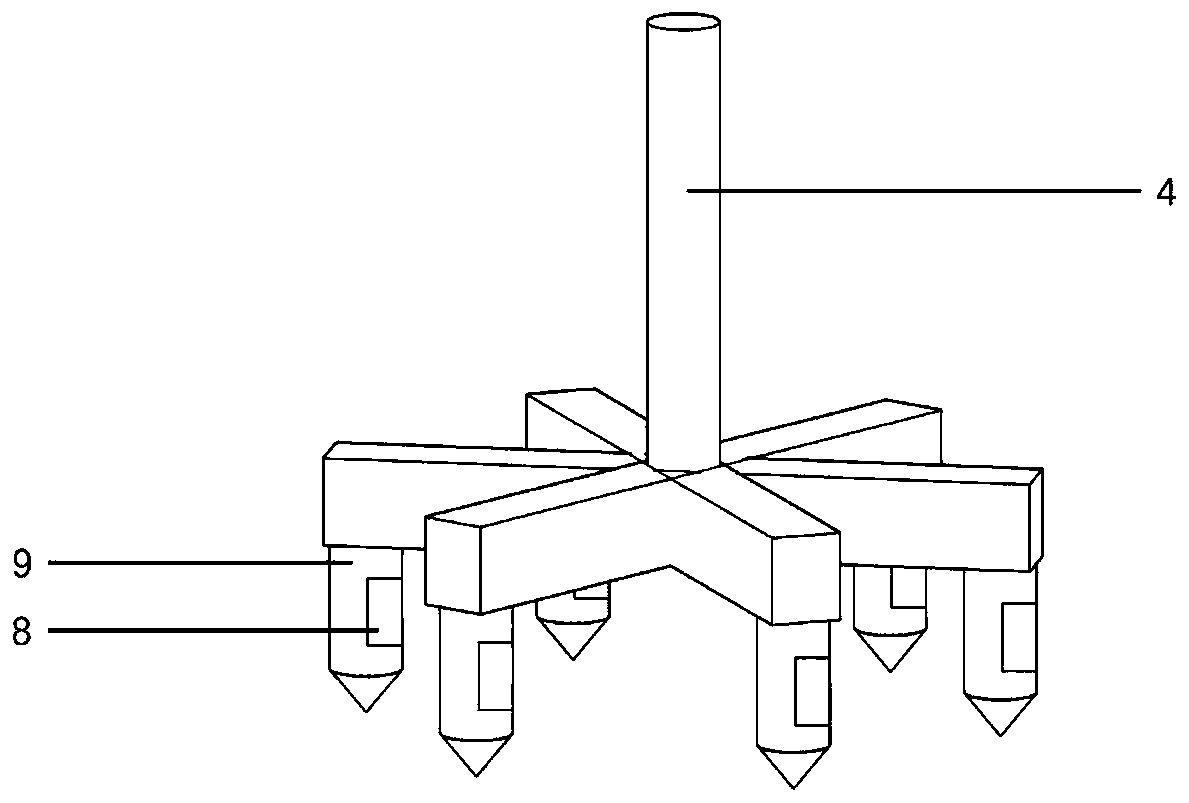

Method used

Image

Examples

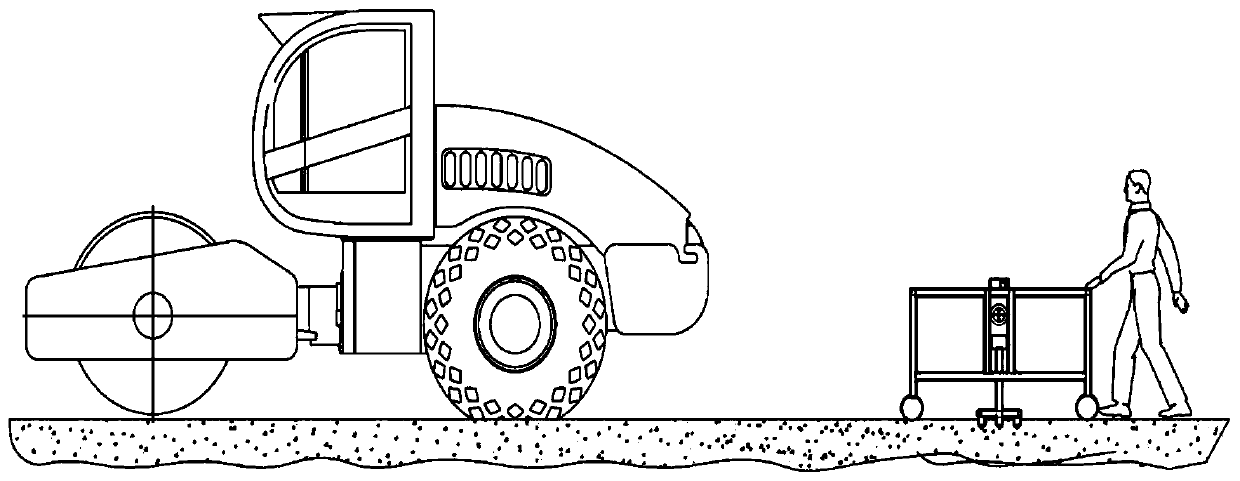

Embodiment 1

[0057] In this embodiment, taking the AC-13C asphalt mixture on the upper layer as an example, the mixture is in the state of being paved. For example, a certain road section is compacted with three types of rollers. The selection of rolling methods is shown in Table 2:

[0058] Table 2 Rolling method of a certain section

[0059]

[0060] The initial pressure should be rolled immediately after the paver. After the static pressure of the steel drum roller is used, the compaction degree of the asphalt mixture should be measured by the nuclear density meter, and the real-time compaction detection of the mixture should be measured by the compaction shear characteristic detection device Index K / K min And the internal temperature T of the mixture. Among them, the electric motor drives the stirring shaft to rotate slowly and at a constant speed. The speed can be freely selected from 5 degrees / min to 10 degrees / min. The compaction status detection indicators are shown in Table 3:

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com