Active cooling double-spray pipe support plate ejection rocket for rocket based combined cyclic engine

An ejection rocket and active cooling technology, which is applied to engine cooling, combined engines, rocket engine devices, etc., can solve problems such as the harsh environment of ejection rocket engines, achieve reliable cooling, reduce flow resistance, and reduce complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

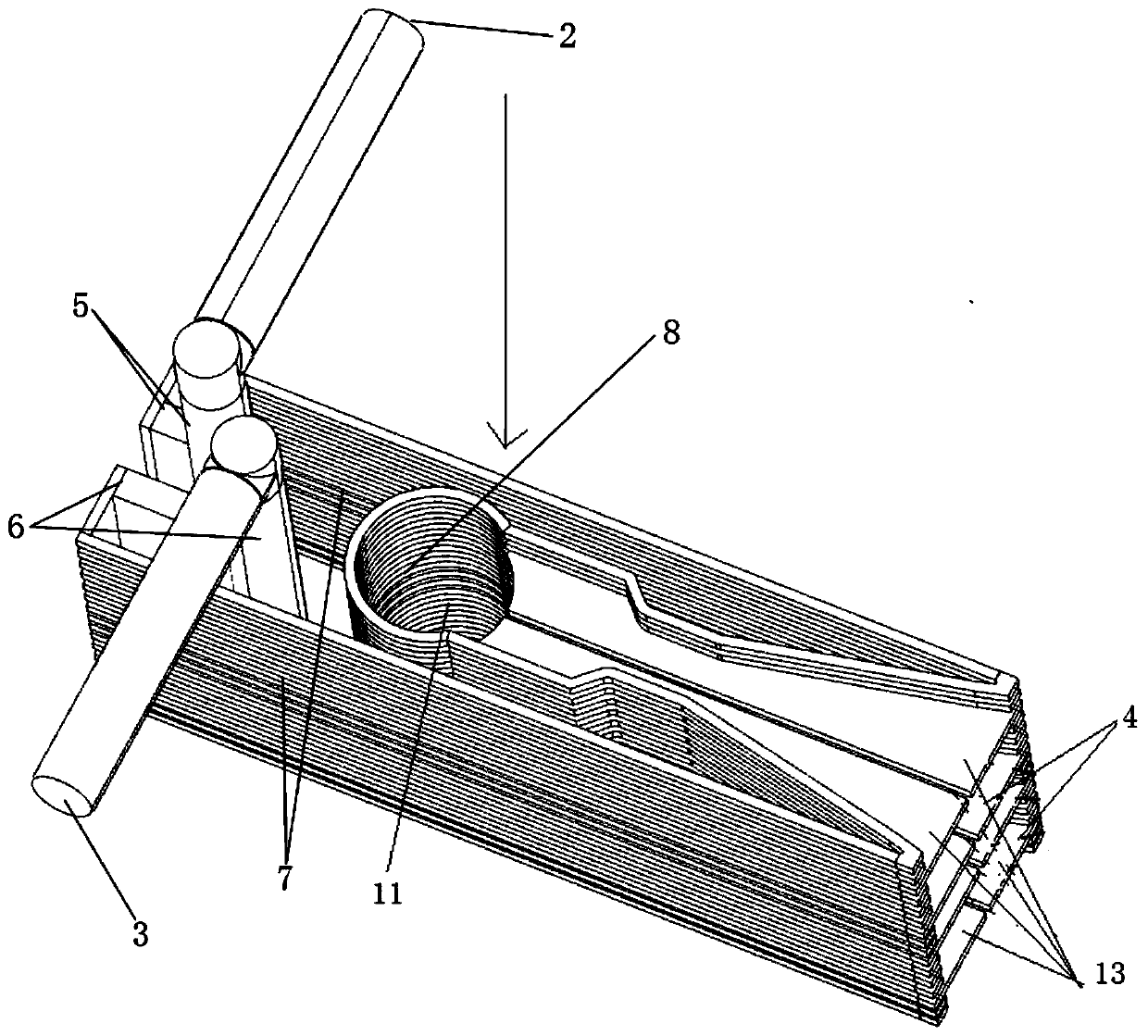

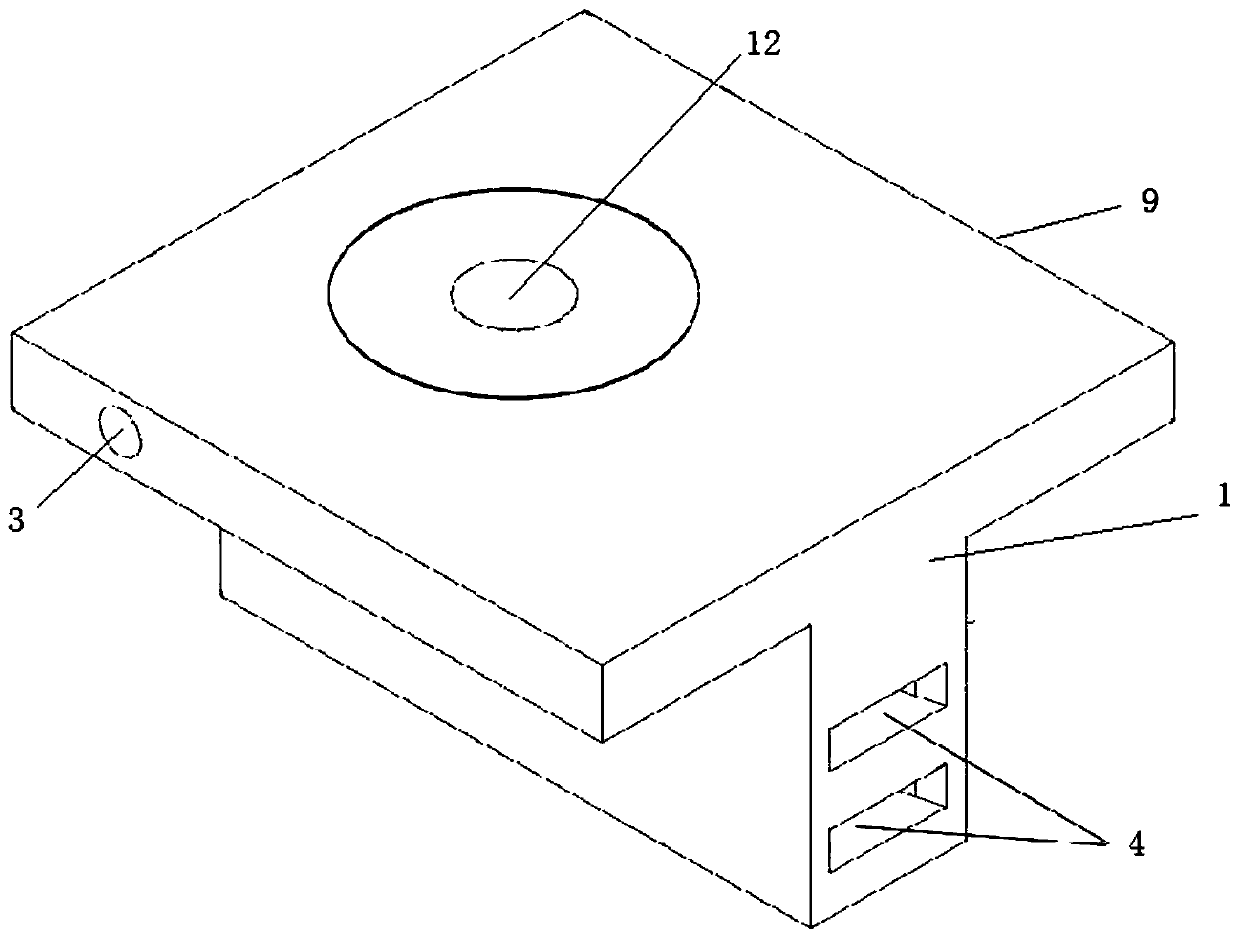

[0022] The present invention is a rocket-based combined cycle engine with active cooling double nozzle support plate ejection rocket, such as figure 1 As shown, the prop ejection rocket body 1 is included, and the prop ejection rocket body 1 is a solid cuboid for longitudinally placing in the isolation section of the engine; the width of the prop ejection rocket body 1 is less than the width of the isolation section, Two independent gas flow passages are formed with the front and rear side walls of the isolation section.

[0023] A vertical combustion chamber 11 is provided near a short side in the prop ejection rocket body 1, and the combustion chamber 11 is a cavity with an open upper end.

[0024] Near the other short side of the combustion chamber 11, there are two vertical Rafal nozzles 4 spaced up and down, communicating with the combustion chamber 11; each Rafal nozzle 4 longitudinally penetrates the support plate to eject the rocket body 1. Its open end communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com