Non-contact prawn physical sign automatic measuring device based on 3D scanner technology

A non-contact, automatic measurement technology, applied in measurement devices, 3D modeling, optical devices, etc., can solve problems such as large measurement errors and shrimp damage, and achieve the effect of improving accuracy and avoiding bumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

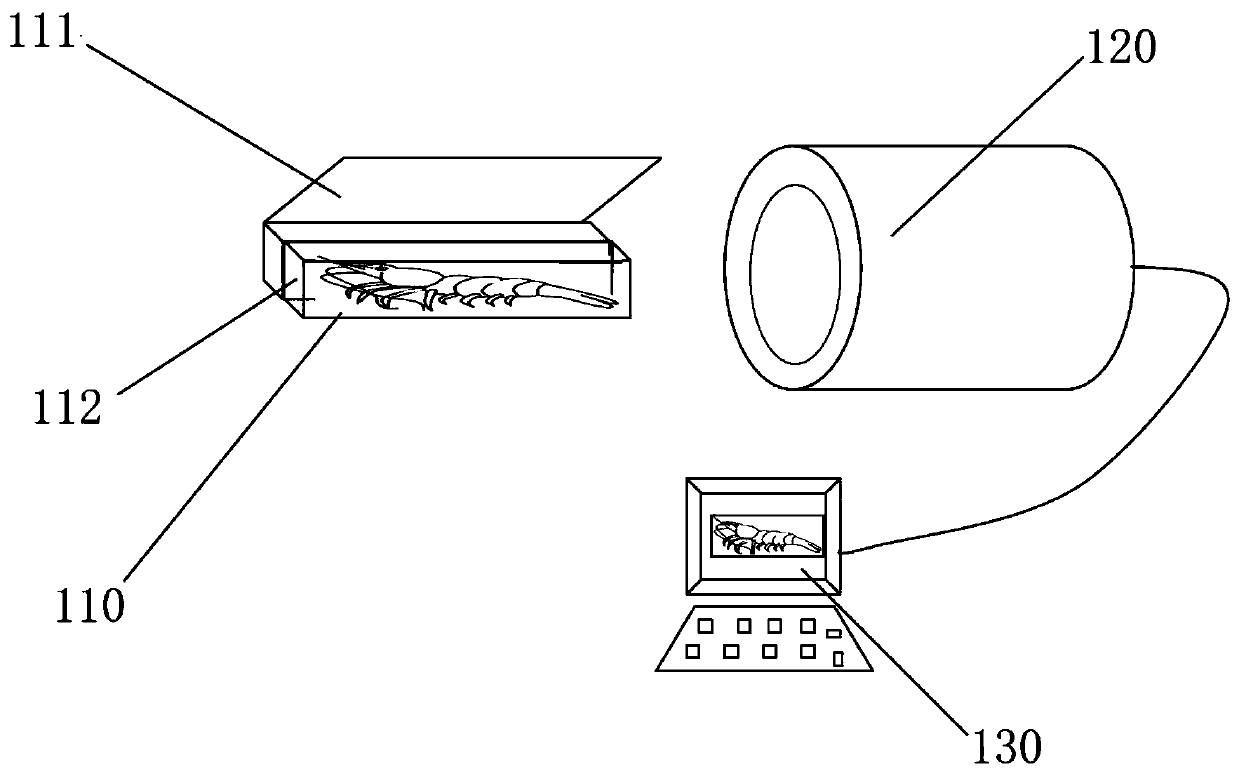

[0023] Please refer to Fig. x, the present embodiment provides a kind of non-contact prawn sign automatic measurement device based on 3D scanner technology, including measuring water tank 110, 3D scanner 120 and computer 130;

[0024] The four walls of the measuring water tank 110 are glass plates for placing live samples of prawns to be measured;

[0025] The 3D scanner 120 includes a 3D scanning camera, a ring light source and a cylindrical body. The cylindrical body is provided with a scanning cavity for placing the measurement tank 110. The 3D scanning camera and the ring light source are arranged on the cylindrical body. scan the inner wall of the cavity;

[0026] The 3D scanning camera is connected to the computer 130 for scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com