Pressure-resistant detection device for production of LCD liquid crystal display screens

A liquid crystal display and detection device technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as low detection efficiency, display screens entering the market, and inability to detect each display screen one by one, so as to improve production quality and high detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

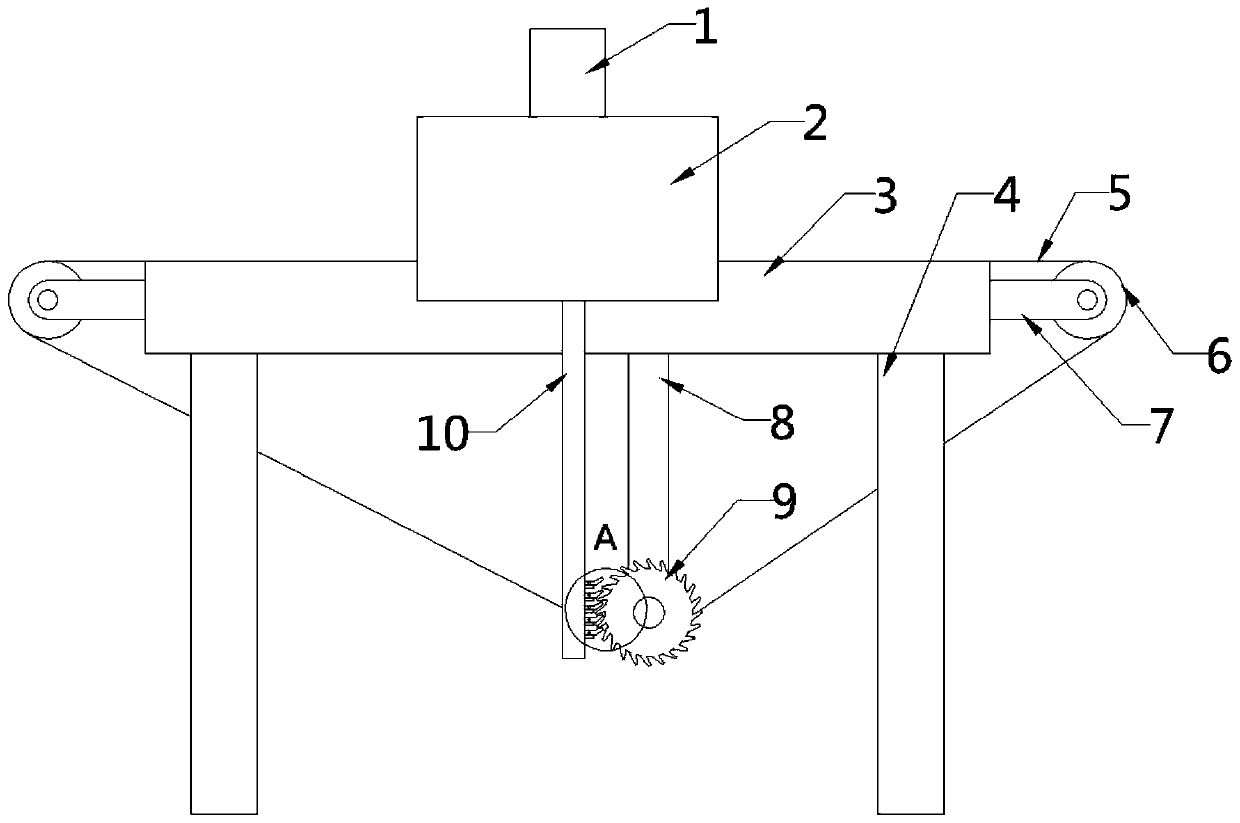

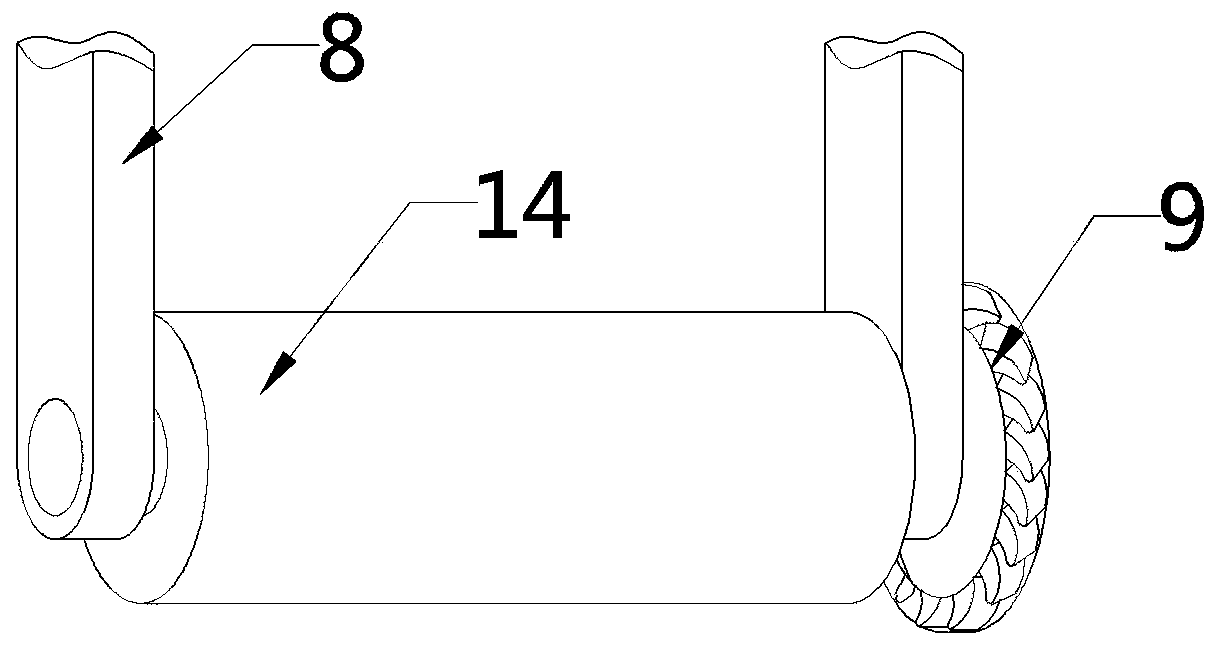

[0020] see Figure 1-4 , the present embodiment provides a pressure-resistant detection device for LCD liquid crystal display production, including a workbench 3 . The upper part of the workbench 3 is provided with a display screen pressing assembly and a display screen conveying assembly. The display screen conveying assembly includes driven pulleys 6 which are respectively rotatably installed on both sides of the workbench 3 and driving pulleys 14 which are rotatably installed below the workbench 3. The two groups of driven pulleys 6 and the drive pulleys 14 are connected by transmission The belt 5 is sleeved and connected. Drive pulley 14 one sides are equipped with gear 9. The display screen pressing assembly controls the gear 9 to rotate intermittently through the transmission assembly.

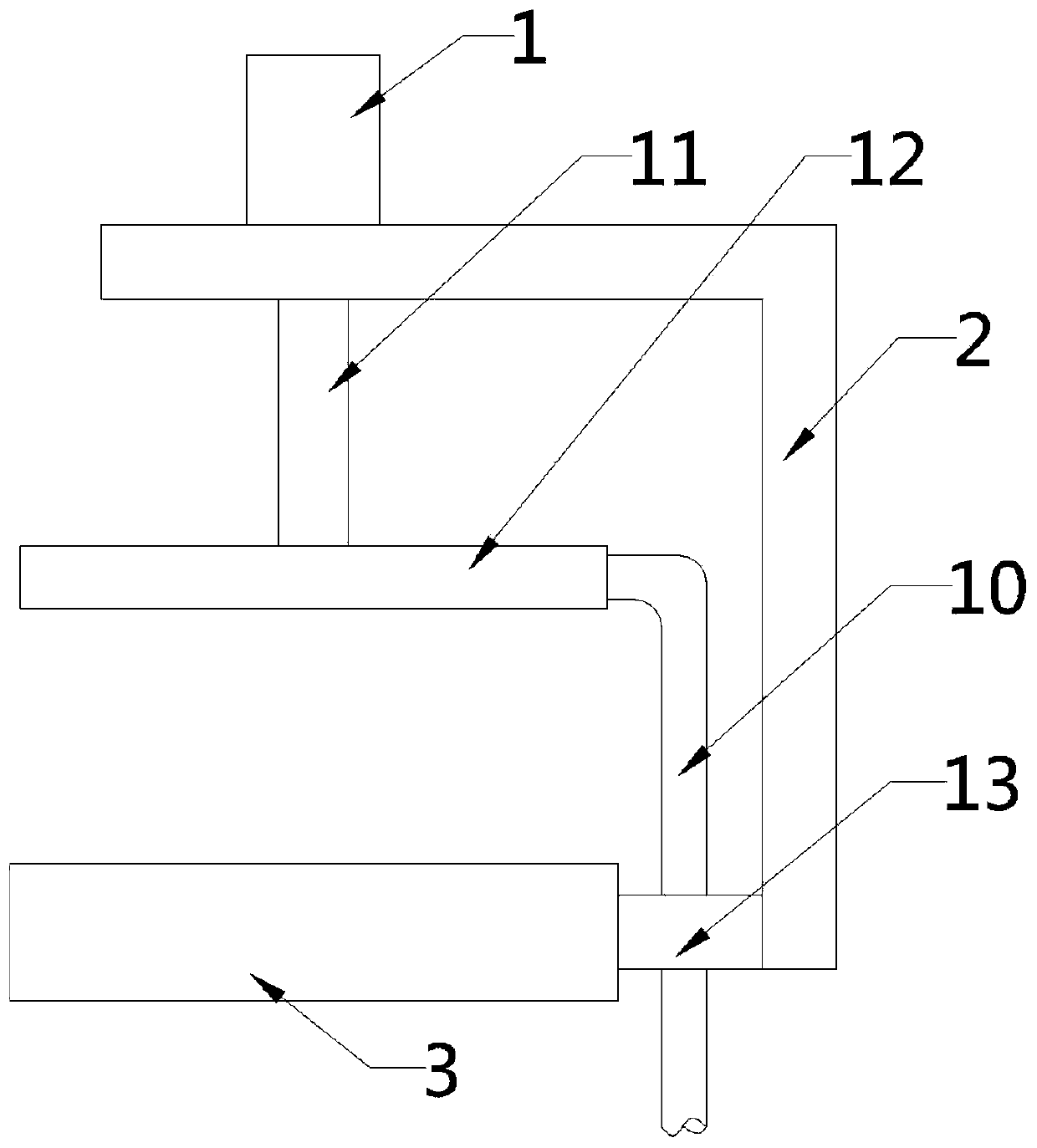

[0021] Support legs 4 are installed at the bottom of the workbench 3 . The display pressing assembly includes a bracket 2 fixedly connected to the side of the workbench 3 . The supp...

Embodiment 2

[0033] see figure 1 , a pressure-resistant detection device for LCD liquid crystal display production. Compared with Embodiment 1, the side of the bracket 2 is fixedly connected to the workbench 3 through several connecting rods 13 arranged at intervals. One end of the driving rod 10 away from the pressing plate 12 passes between the connecting rods 13 and cooperates with the gear 9 to facilitate the up and down movement of the driving rod 10 .

[0034] In the embodiment of the present invention, through the setting of two sets of driven pulleys 6 and the driving pulley 14, the transmission belt 5 forms a triangular structure, and the driving pulley 14 is driven to rotate intermittently by using the up and down movement of the display screen pressing assembly, thereby realizing the transmission of the transmission belt. The intermittent operation of 5 not only realizes the continuous feeding of the display screen, but also provides stable conditions for the pressing operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com