A Structure for Intermittent Operation of an Engine Balance Shaft

A balance shaft and engine technology, applied in the direction of inertial force compensation, etc., can solve the problems of waste of engine output power, etc., and achieve the effects of reducing fuel consumption, improving mechanical efficiency, and improving fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

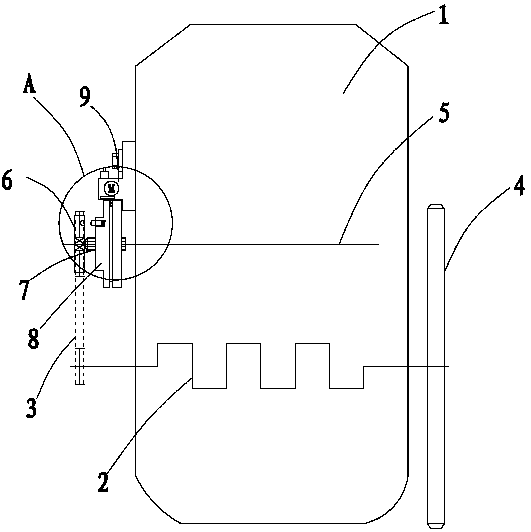

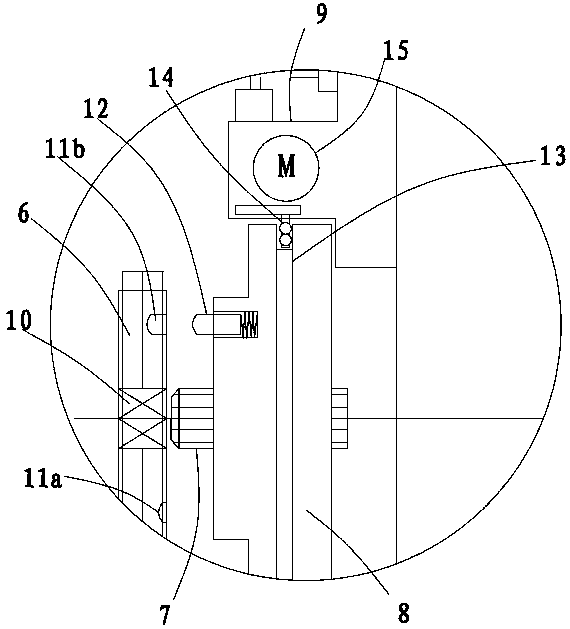

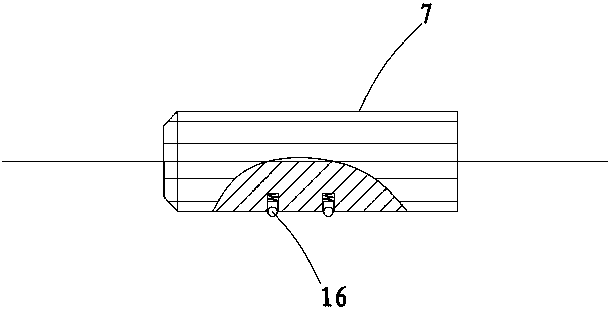

[0021] Embodiment: a kind of engine balance shaft intermittent operation structure, such as figure 1 shown. The device includes an engine 1, and the engine is provided with a crankshaft 2 and a balance shaft 5 parallel to each other. Flywheel 4 is hung on crankshaft 2 rear end, and the front end of crankshaft is provided with sprocket wheel, and balance shaft 5 front ends can be connected with transmission sprocket 6 by bearing 10, and the sprocket wheel of crankshaft front end drives transmission sprocket 6 to rotate by transmission chain 3. On the balance shaft 5, a spline 7 is arranged on the rear side of the transmission sprocket 6, and a sliding connection shaft 8 is slidably sleeved on the spline 7. The engine 1 is also provided with an actuator 9 that toggles and slides the connecting shaft to slide.

[0022] Such as figure 2 As shown, the actuator includes a stepping motor 15 and a paddle 14 that is controlled by the stepping motor to move in translation. The side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com